3957942

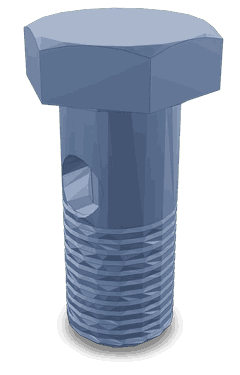

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Banjo Connector Screw 3957942 is a component manufactured by Cummins, designed for use in commercial trucks. This article provides an overview of the banjo connector screw, its function, key features, benefits, and maintenance suggestions.

Basic Concepts of Banjo Connector Screw

A banjo connector screw is a type of fitting used in hydraulic and fuel systems to connect hoses or pipes. It consists of a bolt with an integrated fitting that allows for the secure attachment of hoses. The design includes a banjo fitting, which is a flat, circular component with threaded holes for the screw. This fitting is essential for creating a reliable connection in systems where fluid transfer is critical 1.

Function and Role in Truck Operation

The 3957942 plays a role in the hydraulic and fuel systems of commercial trucks by providing a secure connection point for hoses. It ensures the proper flow of fluids, such as fuel or hydraulic fluid, within the system. This component is integral to maintaining system integrity and performance, as it helps prevent leaks and ensures consistent fluid delivery 2.

Key Features

- Manufactured by Cummins, a reputable engine manufacturer.

- Designed for durability and reliability in heavy-duty applications.

- Features a robust construction to withstand high pressure and vibration.

- Compatible with various hydraulic and fuel system configurations.

Benefits

- Enhances the security of hose connections, reducing the risk of leaks.

- Improves system efficiency by ensuring a consistent fluid flow.

- Easy to install and replace, facilitating maintenance procedures.

- Contributes to the overall reliability of the truck’s hydraulic and fuel systems.

Troubleshooting and Maintenance

- Regular inspection for signs of wear or damage is recommended.

- Ensure proper torque is applied during installation to prevent leaks.

- Replace the banjo connector screw if any corrosion or damage is detected.

- Use appropriate sealants or thread lockers to enhance the connection’s integrity.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation for quality and innovation, Cummins serves commercial, industrial, and transportation markets worldwide. The company’s commitment to excellence ensures that its components, like the 3957942, meet the high standards required for heavy-duty applications.

Compatibility of Banjo Connector Screw Part 3957942 with Cummins Engines

The Banjo Connector Screw part 3957942, manufactured by Cummins, is a crucial component in the fuel and hydraulic systems of various Cummins engines. This part is designed to ensure a secure and leak-proof connection between the banjo fitting and the fuel or hydraulic line. Below is a detailed description of its compatibility with different Cummins engines:

B Series Engines

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

The B series engines, particularly the B4.5 and B6.7 variants, utilize the Banjo Connector Screw part 3957942 in their fuel systems. This screw is essential for maintaining the integrity of the fuel line connections, ensuring that the engine operates smoothly and efficiently.

D Series Engines

- D4.0 CM2620 D103B

The D4.0 CM2620 D103B engine also incorporates the Banjo Connector Screw part 3957942. This part is critical in securing the connections in the engine’s hydraulic and fuel systems, providing a reliable seal that prevents leaks and ensures consistent performance.

F Series Engines

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

The F series engines, including the F3.8 and F4.5 variants, rely on the Banjo Connector Screw part 3957942 for their fuel system connections. This screw is integral in maintaining the pressure and flow of fuel to the engine, ensuring optimal operation.

ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B149

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

The ISB series engines, which include various configurations such as ISB4.5, ISB5.9, and ISB6.7, utilize the Banjo Connector Screw part 3957942 in their fuel systems. This screw is essential for securing the connections in the fuel lines, ensuring that the engine receives the necessary fuel pressure and flow.

ISBE Series Engines

- ISBE4 CM850

The ISBE4 CM850 engine also employs the Banjo Connector Screw part 3957942. This part is critical in maintaining the integrity of the fuel line connections, ensuring that the engine operates smoothly and efficiently.

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

The ISC series engines, including the ISC8.3 variant, use the Banjo Connector Screw part 3957942 in their fuel systems. This screw is essential for securing the connections in the fuel lines, ensuring that the engine receives the necessary fuel pressure and flow.

ISL Series Engines

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

The ISL series engines, including the ISL9 variant, incorporate the Banjo Connector Screw part 3957942 in their fuel systems. This screw is critical in maintaining the integrity of the fuel line connections, ensuring that the engine operates smoothly and efficiently.

ISM Series Engines

- ISM CM876

The ISM CM876 engine also utilizes the Banjo Connector Screw part 3957942. This part is essential for securing the connections in the fuel lines, ensuring that the engine receives the necessary fuel pressure and flow.

Role of Part 3957942 Banjo Connector Screw in Engine Systems

The Part 3957942 Banjo Connector Screw is integral to the efficient operation of various engine systems. It ensures secure and leak-free connections in multiple components, enhancing overall system performance and reliability.

Converter and Catalytic Systems

In converter and catalytic systems, the Banjo Connector Screw plays a significant role in maintaining the integrity of fluid pathways. It secures connections in the plumbing, preventing leaks that could compromise the efficiency of the catalytic converter and the overall emission control system.

Doser and Fluid Systems

For doser and fluid systems, this component is essential in the precise delivery of fluids. It ensures that connections in the doser system remain tight, allowing for accurate dosing of fluids into the exhaust stream. This is particularly important for systems that require consistent fluid levels to operate effectively.

Exhaust Cooler and Water Outlet Tube

In the exhaust cooler and water outlet tube assemblies, the Banjo Connector Screw helps in managing the flow of coolant. It secures connections in the plumbing, ensuring that coolant is efficiently circulated through the exhaust cooler to reduce temperatures and protect downstream components.

Hardware Kit and Corrosion Resistor

When included in a hardware kit, this screw contributes to the durability and longevity of the system by providing corrosion-resistant connections. Its role in resisting corrosion is vital in maintaining the structural integrity of the hardware kit components over time.

Radiator and Turbocharger Plumbing

In radiator and turbocharger plumbing systems, the Banjo Connector Screw ensures that coolant and other fluids are delivered without leaks. This is essential for maintaining optimal operating temperatures and preventing overheating in both the radiator and turbocharger.

Exhaust Recirculation and Water Systems

For exhaust recirculation and water systems, this component secures connections in the plumbing, ensuring that recirculated exhaust gases and water are effectively managed. This helps in reducing emissions and improving engine efficiency.

Upfit Kit and Vent Systems

In upfit kits and vent systems, the Banjo Connector Screw is used to secure connections in additional components added to the engine system. It ensures that these upfit components function as intended without leaks, contributing to the overall performance and safety of the engine.

Engine Coolant and Expansion Tank

Finally, in engine coolant and expansion tank systems, this screw plays a role in maintaining the integrity of coolant pathways. It ensures that coolant is efficiently circulated through the engine and expansion tank, helping to regulate engine temperature and prevent overheating.

Conclusion

The Banjo Connector Screw 3957942 is a critical component in the hydraulic and fuel systems of commercial trucks, ensuring secure and leak-free connections. Its robust construction, compatibility with various Cummins engines, and role in maintaining system integrity make it an essential part for heavy-duty applications. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.