3957203

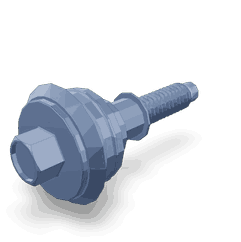

Captive Isolator Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3957203 Captive Isolator Cap Screw is a specialized component designed for use in heavy-duty trucks. Its primary function is to secure various truck components while also providing isolation from vibrations and noise. This screw is integral to maintaining the structural integrity and operational efficiency of truck assemblies.

Basic Concepts

A Captive Isolator Cap Screw is a type of fastener that combines the functions of a traditional cap screw with vibration isolation capabilities. It is designed to secure components in place while minimizing the transmission of vibrations and noise between them. In the context of heavy-duty trucks, these screws play a vital role in ensuring that sensitive components are protected from the harsh vibrations generated by the engine and road conditions 1.

Purpose and Function

The Cummins 3957203 Captive Isolator Cap Screw serves multiple functions within the operation of a truck. Primarily, it secures components such as engine mounts, transmission housings, and other critical parts. Additionally, it isolates these components from vibrations, which helps in reducing noise and preventing wear and tear on both the fastener and the components it secures. This isolation contributes to a smoother operation and extends the lifespan of the truck’s mechanical systems 2.

Key Features

The Cummins 3957203 Captive Isolator Cap Screw is characterized by several key features that enhance its performance. Its design includes an integrated isolator, which is typically made from a resilient material such as rubber or polymer. This isolator sits between the screw and the component, providing the necessary vibration damping. The screw itself is usually made from high-strength steel, ensuring durability and resistance to corrosion. Additionally, the screw features a captive design, meaning the isolator remains attached to the screw, simplifying the installation process and reducing the risk of losing the isolator during maintenance.

Benefits

The use of the Cummins 3957203 Captive Isolator Cap Screw offers several advantages. By effectively isolating vibrations, it contributes to improved engine performance and reduced noise levels within the truck’s cabin. This isolation also helps in minimizing wear and tear on both the fastener and the components it secures, leading to enhanced durability and longevity of the truck’s mechanical systems. Furthermore, the captive design of the screw simplifies maintenance procedures, making it a practical choice for heavy-duty applications 3.

Troubleshooting and Maintenance

Common issues with the Cummins 3957203 Captive Isolator Cap Screw may include wear on the isolator material, leading to reduced effectiveness in vibration isolation, or corrosion on the screw itself. Regular inspection and maintenance are recommended to ensure the screw remains in optimal condition. If wear or corrosion is detected, replacement of the screw is advised to maintain the integrity of the truck’s assembly. Proper torque settings should be observed during installation to ensure the screw is securely fastened without over-tightening, which could damage the isolator or the component being secured.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry, particularly in the production of heavy-duty truck components. The company’s commitment to excellence is reflected in its products, which are designed to meet the demanding requirements of heavy-duty applications.

Captive Isolator Cap Screw in Cummins Engines

The Captive Isolator Cap Screw, part number 3957203, manufactured by Cummins, is an essential component in several of their engine models. This part plays a role in maintaining the structural integrity and operational efficiency of the engines by securing the isolator mounts to the engine block.

ISB and ISB CM2150 Engines

In the ISB and ISB CM2150 engines, the Captive Isolator Cap Screw is used to fasten the engine isolators to the engine block. These engines are known for their robust design and are often used in heavy-duty applications. The isolator mounts help in reducing vibrations and noise, thereby enhancing the overall performance and longevity of the engine.

ISB CM850 Engine

The ISB CM850 engine also utilizes the Captive Isolator Cap Screw to secure the isolator mounts. This engine variant is designed for applications that require high power output and reliability. The isolator mounts are critical in maintaining the engine’s stability and ensuring that the engine operates smoothly under various conditions.

QSB5.9 CM850 Engine

Similarly, the QSB5.9 CM850 engine incorporates the Captive Isolator Cap Screw to attach the isolator mounts. This engine is engineered for demanding applications, providing a balance of power, efficiency, and durability. The isolator mounts, secured by the Captive Isolator Cap Screw, are vital in minimizing the transmission of vibrations and noise, which is crucial for the engine’s performance and the comfort of the operator.

Each of these engines benefits from the precise engineering of the Captive Isolator Cap Screw, ensuring that the isolator mounts remain firmly in place. This helps in maintaining the engine’s structural integrity and operational efficiency, contributing to the overall reliability and performance of the engine.

Role of Part 3957203 Captive Isolator Cap Screw in Engine Systems

The part 3957203 Captive Isolator Cap Screw is integral to the secure and efficient operation of various engine components. In the arrangement of engine assemblies, this component ensures that the valve cover is properly fastened to the engine block. This secure attachment is essential for maintaining the integrity of the valve cover, which houses the valve train components.

By using the Captive Isolator Cap Screw, vibrations and movements that could otherwise affect the valve cover are minimized. This isolation helps in preserving the alignment and function of the valves, which are pivotal for the engine’s combustion process.

Additionally, the screw plays a role in sealing the cover to prevent any leaks of oil or other fluids that could compromise engine performance. Its design allows for easy installation and removal, facilitating maintenance and repairs without the need for additional tools or complex procedures.

Conclusion

In summary, the Cummins 3957203 Captive Isolator Cap Screw is a key element in ensuring that the valve cover remains securely in place, contributing to the overall reliability and efficiency of the engine system. Its design and function are critical in maintaining the structural integrity and operational efficiency of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.