3946085

Twelve Point Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Twelve Point Cap Screw, part number 3946085, is a specialized fastener designed for use in commercial trucks. Cummins, a prominent name in the automotive and heavy-duty truck industry, manufactures this component to meet the rigorous demands of truck operation and maintenance. This part is integral to ensuring the secure attachment of various components within commercial trucks, contributing to their overall structural integrity and performance.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is a type of fastener characterized by its twelve-sided head, which provides a greater number of engagement points compared to traditional hex-head screws. This design reduces the likelihood of cam-out, where the fastener slips out of the driving tool, and allows for increased torque application. Twelve point cap screws are commonly used in mechanical assemblies where high torque and secure fastening are required 1.

Role of the Twelve Point Cap Screw in Truck Operation

The Cummins Twelve Point Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is used to secure various components, ensuring they remain firmly in place under the dynamic conditions experienced during truck operation. By providing a reliable fastening solution, this part helps maintain the structural integrity of the truck, contributing to its safe and efficient performance 2.

Key Features of the Cummins Twelve Point Cap Screw

The Cummins Twelve Point Cap Screw is designed with specific features that enhance its performance and durability. The twelve-point head offers more engagement points than a traditional hex-head, reducing the risk of cam-out and allowing for higher torque application. The screw is made from high-quality materials, ensuring it can withstand the stresses and vibrations encountered in commercial truck applications. Additionally, the design of the screw facilitates easier installation and removal, enhancing maintenance efficiency 3.

Benefits of Using Cummins Twelve Point Cap Screws

Cummins Twelve Point Cap Screws offer several advantages for commercial truck applications. The increased number of engagement points provided by the twelve-point head allows for greater torque application without the risk of cam-out, ensuring a secure fastening. The high-quality materials used in the construction of these screws contribute to their durability and resistance to wear and corrosion. Furthermore, the design of the screw simplifies installation and removal, reducing maintenance time and effort.

Installation Considerations

Proper installation of the Twelve Point Cap Screw is crucial for ensuring optimal performance and longevity. It is recommended to use the appropriate torque wrench to apply the correct amount of torque, avoiding over-tightening which can damage the screw or the component being fastened. Additionally, ensuring that the mating surfaces are clean and free of debris will help achieve a secure and lasting connection.

Maintenance and Troubleshooting

Regular maintenance of the Twelve Point Cap Screw involves inspecting it for signs of wear, corrosion, or damage. If any issues are detected, the screw should be replaced to prevent potential failures. Troubleshooting common issues, such as loosening or corrosion, can often be addressed by re-torquing the screw or applying a corrosion-resistant coating. Adhering to these maintenance practices will help ensure the continued reliable operation of the screw.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for producing high-quality, reliable components that meet the demanding requirements of heavy-duty applications. The company’s commitment to innovation and customer satisfaction has established it as a trusted name in the industry.

Twelve Point Cap Screw 3946085 in Cummins Engines

The Twelve Point Cap Screw 3946085, manufactured by Cummins, is a critical component used in various Cummins engine models. This screw is integral in securing different parts of the engine together, ensuring structural integrity and operational efficiency.

ISB Series Engines

- ISB CM550

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB5.9G CM2180

- ISB11.2 CM2150

The ISB series engines utilize the Twelve Point Cap Screw 3946085 in several key areas, including the fastening of engine blocks, cylinder heads, and other critical components. This screw’s design provides a secure grip, essential for maintaining the alignment and stability of these parts under high operational stresses.

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

- ISC9.0 CM2150

In the ISC series engines, the Twelve Point Cap Screw 3946085 is employed to secure various engine components, ensuring that parts such as the engine block and accessory mounts remain firmly attached. This screw’s robustness is vital for the longevity and performance of these engines.

ISL Series Engines

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

The ISL series engines also benefit from the use of the Twelve Point Cap Screw 3946085. This screw is used in fastening components that require high tensile strength and precision, such as turbo mounts and other critical engine assemblies.

ISX Series Engines

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX series engines incorporate the Twelve Point Cap Screw 3946085 in several high-stress areas, including the fastening of the engine block, cylinder heads, and other critical components. This screw’s design ensures that these parts remain securely fastened, contributing to the engine’s overall performance and durability.

ISZ Series Engines

- ISZ13 CM2150 Z105

In the ISZ13 CM2150 Z105 engine, the Twelve Point Cap Screw 3946085 is used to secure various engine components, ensuring that parts such as the engine block and accessory mounts remain firmly attached.

QSC and QSL Series Engines

- QSC8.3 CM850(CM2850)

- QSC9 CM2250/QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850(CM2850)

- QSX11.9 CM2250 ECF

The QSC and QSL series engines also utilize the Twelve Point Cap Screw 3946085 in various applications, including the fastening of engine blocks, cylinder heads, and other critical components. This screw’s design ensures that these parts remain securely fastened, contributing to the engine’s overall performance and durability.

Role of Part 3946085 Twelve Point Cap Screw in Engine Systems

The Part 3946085 Twelve Point Cap Screw is instrumental in securing and maintaining the integrity of various components within engine systems. Its application spans across multiple critical assemblies, ensuring that each part functions as intended under the demanding conditions of engine operation.

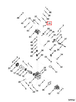

Fuel Injection Pump

In the fuel injection pump, the Twelve Point Cap Screw is used to fasten components that regulate fuel delivery. This includes securing the pump housing to the engine block, ensuring a stable and leak-free connection. The screw’s design allows for precise torque application, which is essential for maintaining the pump’s calibration and performance.

Fuel Pump and Fuel Pump Assembly

For the fuel pump and fuel pump assembly, the Twelve Point Cap Screw plays a role in attaching the pump to its mounting bracket. This secure attachment is vital for the pump’s stability and efficiency, as any movement can affect fuel flow and pressure. The screw’s robustness ensures that the pump remains firmly in place, even under high vibrational stress.

Fuel Pump Mounting

When it comes to fuel pump mounting, the Twelve Point Cap Screw is employed to anchor the pump to the engine or chassis. This secure fastening prevents any shifting that could disrupt fuel supply lines or cause leaks. The screw’s twelve-point design offers enhanced grip, reducing the risk of stripping during installation or removal.

Fuel Systems HD XPI

In high-demand fuel systems like the HD XPI, the Twelve Point Cap Screw is used in various applications, including securing fuel rail components and attaching sensors. Its use ensures that all parts remain in optimal alignment, contributing to the system’s overall efficiency and reliability.

Starting Motor Mounting

For starting motor mounting, the Twelve Point Cap Screw is critical in attaching the starter motor to the engine block. This secure connection is necessary for the starter motor to function correctly, providing the necessary torque to crank the engine. The screw’s design ensures a strong and durable attachment point.

XPI JV Components

Across XPI JV components, the Twelve Point Cap Screw is utilized to fasten various parts, including injector holders and pump components. Its application ensures that these components remain securely in place, which is essential for the precise fuel delivery and engine performance that XPI JV systems are known for.

XPI JV System Cummins HD, XPI JV System Cummins MR, XPI JV System Scania HD, XPI JV System Texas

In the XPI JV systems for Cummins HD, Cummins MR, Scania HD, and Texas engines, the Twelve Point Cap Screw is a common fastener for critical components. It is used in applications such as securing injector pumps, attaching sensor brackets, and fastening fuel line connections. The screw’s reliability and ease of use make it an ideal choice for these high-stress environments.

Conclusion

The Cummins Twelve Point Cap Screw, part number 3946085, is a versatile and essential component in engine systems, providing the necessary security and stability for a wide range of applications. Its design, featuring a twelve-point head, allows for increased torque application and reduced risk of cam-out, making it ideal for high-stress environments. The use of high-quality materials ensures durability and resistance to wear and corrosion, while its design simplifies installation and removal, enhancing maintenance efficiency. Proper installation and regular maintenance are crucial for ensuring the optimal performance and longevity of this part. Cummins’ reputation for producing reliable components further underscores the importance of this fastener in commercial truck and engine applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.