3944061

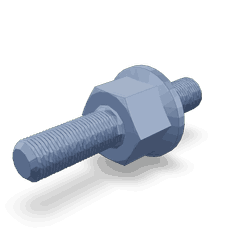

Studded Flange Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Studded flange cap screws are critical components in the assembly and maintenance of commercial trucks. They offer secure fastening solutions that are essential for the integrity and performance of various truck systems. Among these, the 3944061 studded flange cap screw by Cummins is notable for its robust design and reliable performance. This part ensures the secure attachment of components within commercial trucks, contributing to the overall efficiency and safety of the vehicle.

Basic Concepts of Studded Flange Cap Screws

Studded flange cap screws are specialized fasteners that combine the features of a stud and a flanged bolt. They consist of a threaded shaft with a flange at one end and a stud at the other, allowing for secure fastening in applications where regular cap screws may not suffice. The flange provides additional surface area for distribution of clamping force, reducing the risk of damage to the fastened material. Unlike regular cap screws, which are tightened with a nut, studded flange cap screws are typically secured with a cap screw or a nut that engages the stud portion, offering enhanced stability and resistance to loosening 1.

Purpose of the 3944061 Studded Flange Cap Screw

The 3944061 studded flange cap screw by Cummins is designed to play a specific role in the operation of commercial trucks. It is used in various applications where secure and durable fastening is required. This includes attaching critical components such as engine mounts, exhaust systems, and chassis parts. The screw’s design ensures that these components remain firmly in place, even under the demanding conditions encountered in commercial truck operations 2.

Key Features

The 3944061 studded flange cap screw boasts several key features that enhance its performance and durability. Its construction includes a high-strength material, typically alloy steel, which provides excellent resistance to wear and corrosion. The screw features precise threading that ensures a secure fit and easy installation. The flange at one end of the screw distributes clamping force evenly, minimizing the risk of damage to the fastened material. Additionally, the stud design allows for versatile fastening options, accommodating various applications within the truck 3.

Benefits

Using the 3944061 studded flange cap screw offers several benefits. The screw’s design provides improved fastening security, ensuring that components remain firmly attached even in vibrating environments. Its resistance to loosening under vibration makes it ideal for use in commercial trucks, where components are subject to constant movement and stress. Furthermore, the screw’s durable construction enhances its longevity, reducing the need for frequent replacements and maintenance.

Troubleshooting and Maintenance

To ensure the longevity and reliable performance of the 3944061 studded flange cap screw, regular maintenance and troubleshooting are necessary. Signs of wear, corrosion, or failure should be addressed promptly to prevent component detachment or system malfunction. Maintenance tips include periodic inspection for signs of damage, ensuring proper torque during installation to avoid over-tightening, and applying appropriate lubricants to reduce friction and wear.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality and innovation. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications. Cummins’ dedication to excellence is evident in its manufacturing processes, which emphasize precision, durability, and performance.

Compatibility with Cummins Engines

The 3944061 studded flange cap screw is designed to fit a variety of Cummins engines. This part is essential for securing flanges and ensuring a tight seal in various engine applications. Below is a detailed breakdown of the engines with which this part is compatible:

Cummins B Series Engines

- B4.5

- B4.5 RGT

- B6.7 CM2350 B135B

- B6.7 CM2670 B135B

- B6.7 CM2670 B164C

Cummins ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

Cummins ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

Cummins ISC Series Engines

- ISC CM850

Cummins ISL Series Engines

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

This part is integral for maintaining the structural integrity and operational efficiency of these engines by ensuring that flanges are securely fastened, preventing leaks and maintaining pressure integrity.

Role of the 3944061 Studded Flange Cap Screw in Engine Systems

The 3944061 studded flange cap screw is integral to the secure assembly and operation of various engine components. Its primary function is to provide a robust fastening solution that ensures components remain firmly in place under the dynamic and demanding conditions of engine operation.

Compressor and Air Systems

In compressor and air systems, the 3944061 studded flange cap screw is used to secure the compressor cover and ensure a tight seal. This is essential for maintaining the efficiency of the compressor and preventing air leaks, which could compromise the performance of the air system.

Electrical and Wiring Systems

For electrical components such as the electronic control module wiring harness and engine control wiring harness, the 3944061 studded flange cap screw plays a role in securing these harnesses to the engine block or other structural components. This ensures that the wiring remains organized and protected from vibrations and mechanical stress.

Cooling and Plumbing Systems

In cooling systems, particularly those involving compressor coolant plumbing and auxiliary pump plumbing, the 3944061 studded flange cap screw is employed to fasten components such as the oil fill and oil level gauge. This ensures that coolant and oil systems remain sealed and operate efficiently, contributing to the overall thermal management of the engine.

Mounting and Structural Integrity

The 3944061 studded flange cap screw is also vital in mounting systems. It is used in the mounting of compressor coolant and lifting arrangements, ensuring that these components are securely attached to the engine frame. This is particularly important for components like the lifting bracket and long block, where structural integrity is paramount.

Noise Reduction and Emission Control

In systems designed for noise reduction and emission control, such as those involving the nitrogen oxide sensor and turbocharger, the 3944061 studded flange cap screw helps in securing covers and housings. This ensures that these systems function correctly and contribute to reducing emissions and noise levels.

Fuel Systems

Within fuel systems, including the fuel filter and fuel module coolant pump, the 3944061 studded flange cap screw is used to secure components, ensuring that fuel lines and filters are held in place. This is essential for maintaining the integrity of the fuel delivery system and ensuring consistent engine performance.

Conclusion

Overall, the 3944061 studded flange cap screw is a versatile and essential component in various engine systems, providing the necessary fastening strength and reliability required for the secure operation of engine components.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.