3943995

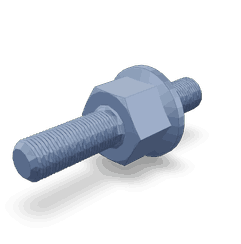

Studded Flange Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3943995 Studded Flange Cap Screw is a specialized fastener designed for heavy-duty truck applications. Its purpose is to securely attach flanges and other components within the truck’s mechanical system. This screw is significant due to its robust design and reliable performance, ensuring the integrity and efficiency of the truck’s operations.

Basic Concepts

A Studded Flange Cap Screw, such as the Cummins 3943995, consists of a threaded shaft with a hexagonal head and a flange at one end. The flange provides additional surface area for securing components, while the studded design allows for easy installation and removal. This screw functions by threading into a corresponding nut or tapped hole, creating a secure connection that can withstand significant stress and vibration.

Role in Truck Operation

The 3943995 Studded Flange Cap Screw plays a role in the operation of a truck by securing flanges and other critical components. It is commonly used in applications where high torque and secure fastening are required, such as in the engine, transmission, and chassis systems. By providing a stable and reliable connection, this screw helps maintain the structural integrity and performance of the truck.

Key Features

The Cummins 3943995 Studded Flange Cap Screw features a durable material composition, typically made from high-strength steel to withstand heavy loads and harsh environments. It has a coarse threading type, which allows for quick and secure fastening. The design specifications include a hexagonal head for easy tightening with standard tools and a flange that enhances the screw’s holding power.

Benefits

Using the Cummins 3943995 Studded Flange Cap Screw offers several benefits. Its durable material composition ensures long-lasting performance, while the coarse threading type provides a secure and stable connection. The flange design enhances the screw’s holding power, reducing the risk of loosening under vibration. Additionally, the screw’s reliable performance contributes to the overall efficiency and safety of the truck.

Installation Process

Proper installation of the Cummins 3943995 Studded Flange Cap Screw involves several steps to ensure optimal performance and longevity. Begin by cleaning the mating surfaces to remove any debris or contaminants. Thread the screw into the corresponding nut or tapped hole by hand to avoid cross-threading. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring a secure connection without over-tightening.

Maintenance Tips

To prolong the lifespan of the Cummins 3943995 Studded Flange Cap Screw and ensure continued reliable operation, follow these maintenance tips. Regularly inspect the screw for signs of wear, corrosion, or damage. Clean the screw and mating surfaces periodically to remove dirt and debris. Re-torque the screw at recommended intervals to maintain the secure connection. Replace the screw if any significant wear or damage is detected.

Troubleshooting Common Issues

Common problems associated with the Cummins 3943995 Studded Flange Cap Screw include loosening, corrosion, and damage. To address these issues, first, ensure that the screw is properly torqued during installation. Use corrosion-resistant coatings or materials to protect the screw from environmental factors. Inspect the screw regularly for signs of wear or damage, and replace it if necessary to maintain the integrity of the connection.

Manufacturer Information

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins offers a wide range of products designed to meet the demanding needs of heavy-duty truck applications. The company’s reputation for excellence is built on its dedication to engineering excellence, customer satisfaction, and continuous improvement.

Compatibility with Cummins Engines

The Studded Flange Cap Screw (part number 3943995) is compatible with various Cummins engines, ensuring secure fastening of flanges and maintaining the engine’s performance. Below is a detailed overview of the engines with which this part is compatible:

ISB Series Engines

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISX Series Engines

- ISX CM871

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL9 CM2250

ISM Series Engines

- ISM CM570/870

- ISM CM876

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB5.9 CM850

- QSB6.7 M CM2250

QSC and QSL Series Engines

- QSC8.3 CM850(CM2850)

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

QSF Series Engine

- QSF3.8 CM2350 F107

Role in Engine Systems

The 3943995 Studded Flange Cap Screw is integral to the secure assembly and operation of various engine components. Its role spans across multiple systems, ensuring that parts remain firmly attached and function as intended.

Actuator Bracket Kit

In the actuator bracket kit, the 3943995 screw is used to fasten the bracket securely to the engine block. This ensures the actuator operates within the correct parameters, maintaining efficient control over components like the turbocharger or exhaust gas recirculation (EGR) mixer ejector.

Aftermarket Turbocharger

When installing an aftermarket turbocharger, the 3943995 screw is employed to attach the turbocharger to the engine block or manifold. This secure attachment is vital for withstanding the high pressures and temperatures generated during operation.

Charge Air Bypass and Crankcase Breather Arrangements

In both charge air bypass and crankcase breather arrangements, the screw helps in mounting and securing various plumbing components. This includes connections to the air intake and crankcase breather, ensuring a sealed and efficient system.

Electronic Control Module Wiring Harness

The electronic control module (ECM) wiring harness often requires secure mounting points. The 3943995 screw is used to attach the harness to the engine block or other stable surfaces, preventing wire damage and ensuring reliable signal transmission.

Exhaust Gas Recirculation Mixer Ejector

For the exhaust gas recirculation (EGR) mixer ejector, the screw is used in the mounting process. This ensures the ejector is correctly positioned to mix exhaust gases with the intake air, promoting efficient combustion and reduced emissions.

Oil Level Gauge and Oil Pan

In the oil level gauge and oil pan systems, the screw is utilized to secure components in place. This is essential for maintaining the integrity of the oil system, ensuring accurate oil level readings and preventing leaks.

Turbine Housing and Turbocharger Kit

Within the turbine housing and turbocharger kit, the 3943995 screw plays a role in securing various components. This includes attaching the turbine housing to the engine and ensuring the turbocharger kit is correctly installed and operational.

Water Pump Drive

Finally, in the water pump drive system, the screw is used to secure the drive mechanism to the engine block. This ensures the water pump operates efficiently, maintaining proper coolant circulation and engine temperature regulation.

Conclusion

The Cummins 3943995 Studded Flange Cap Screw is a critical component in the assembly and maintenance of various Cummins engines. Its robust design and reliable performance ensure secure fastening of flanges and the efficient operation of engine systems. Proper installation, maintenance, and troubleshooting are essential to maximize the lifespan and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.