This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

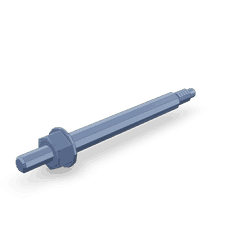

The 3943718 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a leading manufacturer in the commercial truck industry. This component is designed for use in various truck systems, where it plays a role in ensuring the secure attachment and reliable operation of critical components.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that combines the features of a stud and a cap screw. It is characterized by a threaded section that extends beyond the head, allowing it to be used with a nut on the opposite side of the material being fastened. In mechanical systems, these screws are used to provide a strong and durable connection between components. Within the context of a truck’s components, they are often employed in applications where high strength and resistance to vibration are required 1.

Purpose of the 3943718 Studded Flange Cap Screw

This Cummins part is utilized in the operation of trucks to secure and maintain the integrity of various components. It is particularly important in applications where components are subject to significant stress or vibration, as it provides a robust connection that helps to prevent loosening over time. This screw plays a role in ensuring that components remain firmly attached, which is vital for the safe and efficient operation of the vehicle.

Key Features

The 3943718 features a design that includes a studded section extending beyond the head, which allows for the use of a nut on the opposite side. It is made from high-quality materials that offer excellent strength and durability. The threading on the screw is precise, ensuring a secure fit within the components it connects. Additionally, the screw may have unique attributes such as a flanged head that provides extra surface area for distribution of clamping force, enhancing its performance and durability.

Benefits

Using the 3943718 offers several advantages. It provides improved stability in connections, which is particularly beneficial in applications where components are subject to vibration. The screw’s design also contributes to enhanced load-bearing capabilities, ensuring that it can withstand the stresses of truck operation. Furthermore, its resistance to corrosion and wear helps to ensure longevity and reliable performance over time.

Installation Process

Proper installation of the 3943718 involves several steps. First, ensure that the mating surfaces are clean and free from debris. Use the appropriate tools to begin threading the screw into the component. It is important to follow the specified torque settings to ensure that the screw is tightened to the correct level, providing a secure connection without over-tightening, which could damage the screw or the component. Take care to align the screw correctly with the nut on the opposite side to ensure a proper fit.

Troubleshooting and Maintenance

Common issues with the 3943718 may include corrosion, loosening, or damage. Regular inspection for signs of wear or corrosion is recommended to identify potential problems early. If loosening is detected, the screw should be re-tightened to the specified torque settings. In cases of significant corrosion or damage, replacement of the screw may be necessary to maintain the integrity of the connection.

Compatibility and Applications

The 3943718 is typically used in various applications within a truck’s system, including but not limited to, engine components, transmission systems, and chassis assemblies. It is designed to be compatible with specific components and truck models, ensuring a precise fit and reliable performance.

Safety Considerations

When working with the 3943718, it is important to follow safety guidelines. This includes proper handling to avoid injury, secure storage to prevent damage or loss, and appropriate disposal practices to minimize environmental impact. Always use the correct tools and follow manufacturer recommendations to ensure safe and effective use of the screw.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted partner for truck manufacturers and operators worldwide.

Studded Flange Cap Screw (Part 3943718) in Cummins Engines

The Studded Flange Cap Screw, part number 3943718, is a component in the assembly and maintenance of various Cummins engines. This part is designed to secure flanges and other components, ensuring a tight and reliable connection.

Application in ISB CM550 and QSB5.9 44 CM550 Engines

In the ISB CM550 engine, the Studded Flange Cap Screw is utilized in several key areas where flanges need to be fastened securely. This includes connections in the exhaust system, fuel system, and other critical junctures where a robust fastening solution is necessary to maintain system integrity and performance.

Similarly, in the QSB5.9 44 CM550 engine, the Studded Flange Cap Screw plays a role in securing flanges within the engine’s architecture. This ensures that components such as exhaust manifolds, fuel injectors, and other critical parts are held firmly in place, contributing to the engine’s overall reliability and efficiency.

Importance of the Studded Flange Cap Screw

The use of studded flange cap screws in these engines is important for several reasons:

- Enhanced Security: The studs provide a secure grip, preventing loosening over time, which is vital for maintaining engine performance and safety.

- Ease of Maintenance: The design allows for easy removal and replacement, facilitating routine maintenance and repairs.

- Durability: Made from high-quality materials, these screws are built to withstand the harsh conditions within the engine compartment, ensuring longevity and reliability.

By integrating the Studded Flange Cap Screw into their design, Cummins ensures that their engines maintain high standards of performance and durability, providing reliable service across various applications.

Role of Part 3943718 Studded Flange Cap Screw in Engine Systems

In the intricate assembly of engine systems, the Part 3943718 plays a role in ensuring the secure attachment and reliable operation of various components.

Cover Attachment

The studded flange cap screw is instrumental in fastening the engine cover. This cover protects internal components from external contaminants and provides a streamlined enclosure for the engine. By securely attaching the cover, the screw helps maintain the integrity of the engine’s sealed environment, which is essential for optimal performance and longevity.

Valve Assembly

In valve assemblies, the studded flange cap screw is used to secure valve covers and other related components. This ensures that the valve train operates within specified tolerances, contributing to efficient valve operation and sealing. The secure attachment provided by the screw is vital for maintaining the precision required in valve timing and function, directly influencing the engine’s overall efficiency and reliability 2.

Conclusion

The 3943718 Studded Flange Cap Screw is a critical component in the assembly and maintenance of various Cummins engines. Its design and features contribute to enhanced security, ease of maintenance, and durability, ensuring that engines maintain high standards of performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.