3943592

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

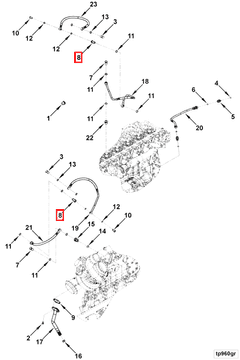

The Banjo Fitting Connector Screw, specifically Part #3943592 by Cummins, is a component used in the maintenance and operation of commercial trucks. Cummins, a well-respected manufacturer in the industry, produces this part to ensure reliable and efficient truck performance. This fitting screw is integral to the fluid transfer systems within trucks, facilitating the connection between hoses and pipes.

Basic Concepts of Banjo Fitting Connector Screw

A Banjo Fitting Connector Screw is a type of fitting used to connect hoses to pipes or other components in fluid transfer systems. It consists of a banjo bolt, a gasket, and a nut. The banjo bolt features a hollow, cylindrical body with ports on the side for hose attachment. The gasket ensures a seal between the fitting and the connected component, while the nut secures the assembly. This fitting allows for the transfer of fluids such as hydraulic oil, fuel, or coolant within the truck’s system 1.

Role of the 3943592 Banjo Fitting Connector Screw in Truck Operation

The 3943592 Banjo Fitting Connector Screw plays a role in the fluid transfer systems of commercial trucks by providing a secure and leak-proof connection between hoses and pipes. It is typically used in hydraulic systems, fuel lines, and cooling systems. Its placement varies depending on the specific system it serves, but it is commonly found in areas where flexible hoses need to be connected to rigid pipes or components. The fitting ensures that fluids are transferred efficiently and without leaks, contributing to the overall performance and reliability of the truck 2.

Key Features of the 3943592 Banjo Fitting Connector Screw

The 3943592 Banjo Fitting Connector Screw is designed with several key features to enhance its performance and durability. It is made from high-quality materials, such as stainless steel, which provide resistance to corrosion and wear. The fitting includes a precision-machined banjo bolt with ports for secure hose attachment. A high-quality gasket is used to create a reliable seal, preventing fluid leaks. The design of the fitting allows for easy installation and maintenance, ensuring that it can be quickly replaced or repaired if necessary 3.

Benefits of Using the 3943592 Banjo Fitting Connector Screw

Using the 3943592 Banjo Fitting Connector Screw offers several advantages in truck operations. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The precise design of the fitting allows for efficient fluid transfer, contributing to the overall performance of the truck’s systems. The secure seal provided by the gasket prevents leaks, which can lead to system failures or inefficiencies. Additionally, the ease of installation and maintenance makes it a practical choice for commercial truck fleets 4.

Installation Process

Installing the 3943592 Banjo Fitting Connector Screw involves several steps to ensure a proper and secure connection. First, the fitting area should be cleaned to remove any debris or old gasket material. The banjo bolt is then inserted into the port, and the hose is attached to the ports on the bolt. A new gasket is placed over the bolt, and the nut is threaded onto the bolt to secure the assembly. It is important to tighten the nut to the manufacturer’s specified torque to ensure a proper seal without over-tightening, which could damage the fitting or gasket.

Troubleshooting Common Issues

Common issues with the 3943592 Banjo Fitting Connector Screw may include leaks, difficulty in installation, or corrosion. Leaks can often be traced to a damaged or worn gasket, which may need to be replaced. Difficulty in installation may indicate that the fitting area is not clean or that the wrong size fitting is being used. Corrosion can be addressed by ensuring that the fitting is made from corrosion-resistant materials and by regularly inspecting and maintaining the fitting to prevent buildup.

Maintenance Tips

Regular maintenance of the 3943592 Banjo Fitting Connector Screw is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or leaks. The gasket should be checked and replaced if necessary to maintain a secure seal. The fitting should be cleaned regularly to remove any buildup or debris that could affect its performance. Following the manufacturer’s torque specifications during installation and maintenance will help prevent damage to the fitting.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its high-quality engines, components, and systems. Founded in 1919, Cummins has a long history of innovation and excellence in the production of diesel engines and related technologies. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, designed to meet the demanding needs of commercial truck operators. Cummins is recognized for its commitment to quality, reliability, and customer satisfaction, making it a trusted name in the industry.

Cummins Part 3943592: Banjo Fitting Connector Screw in Engine Applications

The Cummins part 3943592, a Banjo Fitting Connector Screw, is a critical component in various engine systems. This part is designed to ensure a secure and leak-proof connection between fuel lines, hydraulic lines, or other fluid lines and the engine components. Its application spans across a range of Cummins engines, ensuring compatibility and reliability in demanding environments.

ISB (Chrysler) Engines

The ISB engines, developed in collaboration with Chrysler, utilize the Banjo Fitting Connector Screw to maintain the integrity of fluid lines. This is particularly important in maintaining the performance and safety of the engine by preventing leaks that could compromise system functionality.

ISC Series Engines

The ISC series engines, including the ISC CM2150, ISC CM554, and ISC CM850, benefit from the use of the Banjo Fitting Connector Screw. These engines are known for their robust design and efficiency, and the secure connection provided by this part is essential for their operation.

ISC8.3 Series Engines

The ISC8.3 CM2250 engine also incorporates the Banjo Fitting Connector Screw. This engine is part of the ISC8.3 series, which is designed for heavy-duty applications, requiring reliable and durable components to handle the rigors of continuous operation.

ISL Series Engines

The ISL series engines, such as the ISL CM2150, ISL CM554, ISL9 CM2150 SN, and ISL9 CM2250, are another group where the Banjo Fitting Connector Screw is utilized. These engines are known for their power and efficiency, and the secure connections provided by this part are crucial for maintaining system performance.

QSC and QSL Series Engines

The QSC8.3 CM554, QSC9 CM2250/QSL9 CM2250, and QSL9 CM554 engines also integrate the Banjo Fitting Connector Screw. These engines are designed for specific applications, and the secure connections provided by this part are essential for their reliable operation.

Role of Part 3943592 Banjo Fitting Connector Screw in Engine Systems

The 3943592 Banjo Fitting Connector Screw is an integral component in various engine systems, ensuring secure and efficient connections in critical fluid pathways.

In fuel plumbing systems, this fitting is employed to connect fuel lines to injectors or fuel rails. Its design allows for a leak-proof seal, maintaining consistent fuel pressure and delivery, which is essential for optimal engine performance and fuel efficiency.

Within general plumbing systems, the Banjo Fitting Connector Screw is utilized to join different sections of hoses or pipes, providing a robust connection that can withstand high pressures and temperatures. This reliability is vital in systems where fluid dynamics and pressure maintenance are paramount.

In turbocharger systems, this fitting plays a significant role in connecting the turbocharger to the intercooler or other components. It ensures that the pressurized air flow is maintained without leaks, which is essential for the turbocharger’s efficiency and the overall performance of the engine.

For turbocharger plumbing, the Banjo Fitting Connector Screw is often used in the oil feed and return lines. It provides a secure connection that can handle the high pressures and temperatures associated with turbocharger lubrication, ensuring that the turbocharger operates smoothly and reliably.

Overall, the 3943592 Banjo Fitting Connector Screw is a key component in maintaining the integrity and efficiency of various engine systems, facilitating secure and reliable fluid connections.

Conclusion

The 3943592 Banjo Fitting Connector Screw by Cummins is a vital component in the fluid transfer systems of commercial trucks and various engine applications. Its design ensures secure and leak-proof connections, contributing to the overall performance, reliability, and safety of the systems it serves. Regular maintenance and proper installation are essential to maximize the benefits of this fitting.

-

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines, The MIT Press, 2010.

↩ -

Klaus Mollenhauer and Helmut Tschoeke, Handbook of Diesel Engines, Springer, 2010.

↩ -

Clive Gifford, Cars Encyclopedia, DK Publishing, 2014.

↩ -

Nicholas Goodnight and Kirk VanGelder, Automotive Braking Systems CDX Master Automotive Technician Series, Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.