This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

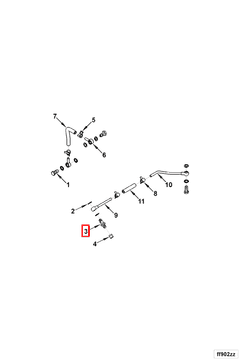

The Cummins 3939915 Banjo Connector Screw Assembly is a specialized component designed for use in commercial trucks. This assembly is integral to the operation of these vehicles, facilitating the transfer of fluids within the hydraulic and fuel systems. Its design ensures reliable performance under the demanding conditions typically encountered in commercial trucking operations.

Basic Concepts

The Banjo Connector Screw Assembly operates on fundamental principles of fluid dynamics and mechanical engineering. Its design incorporates a banjo bolt, which is a type of bolt with a hollow, tubular section that allows fluid to pass through. This assembly is engineered to connect hoses or pipes to various components within the truck’s system, ensuring a secure and leak-free connection. The screw assembly plays a role in maintaining the integrity of the fluid pathways, which is vital for the efficient operation of the truck 1.

Purpose and Function

In the context of a truck’s hydraulic and fuel systems, the 3939915 plays a role in facilitating the transfer of fluids and regulating pressure. It ensures that fluids such as hydraulic oil or fuel are delivered to their intended destinations with minimal loss or leakage. This assembly contributes to the overall efficiency and reliability of the truck’s systems by providing a stable and secure connection point for fluid lines.

Key Features

The 3939915 is characterized by several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design includes precision-machined threads and a robust banjo bolt, which contribute to a secure fit and reliable operation. Additionally, the assembly may feature o-rings or gaskets to prevent leaks, further enhancing its functionality in demanding applications.

Benefits

The use of the Banjo Connector Screw Assembly offers several advantages. It contributes to improved system efficiency by ensuring a secure and leak-free connection, which is particularly important in high-pressure systems. The durable construction of the assembly enhances the reliability of the truck’s hydraulic and fuel systems, reducing the likelihood of failures or leaks. Furthermore, its design allows for easy installation and maintenance, which can save time and resources in commercial truck operations 2.

Installation and Usage

Proper installation of the 3939915 is vital to ensure optimal performance and longevity. It is recommended to follow manufacturer guidelines for torque specifications and sealing procedures to achieve a secure fit. Regular inspection of the assembly for signs of wear or damage is also advised to prevent potential issues. Users should ensure that all connections are tight and that no fluid leaks are present after installation.

Troubleshooting

Common issues with the 3939915 may include leaks, loose connections, or corrosion. To address these problems, it is important to inspect the assembly for any visible damage or wear. Tightening connections or replacing worn components can often resolve these issues. In cases of severe corrosion, replacement of the assembly may be necessary to restore system integrity.

Maintenance Tips

Regular maintenance of the 3939915 is key to ensuring its continued reliable operation. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the assembly and its connections can prevent the buildup of contaminants that may affect performance. Additionally, ensuring that all seals and gaskets are in good condition and replacing them as needed will help maintain a leak-free system.

Safety Considerations

When working with the 3939915, it is important to observe safety guidelines to prevent accidents. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against fluid spills or debris. Ensuring that the truck’s systems are depressurized before performing any maintenance or repairs on the assembly is also crucial to avoid injury from pressurized fluid 3.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. The company is known for its commitment to quality and innovation in the design and production of automotive components. Cummins’ products, including the 3939915, are engineered to meet the rigorous demands of commercial truck applications, ensuring reliability and performance in a variety of operating conditions.

Application in Cummins Engines

ISB CM550 and ISB CM850

In the ISB CM550 and ISB CM850 engines, the 3939915 is integral to the fuel system. It ensures that the fuel lines are tightly secured to the fuel fittings, preventing any fuel leaks that could compromise engine performance or safety. The precision of this component is crucial in maintaining the engine’s efficiency and reliability.

QSB5.9 CM850

Similarly, in the QSB5.9 CM850 engine, the 3939915 plays a vital role in both the fuel and hydraulic systems. This engine, known for its robust performance, relies on this part to maintain the integrity of its hydraulic connections. The secure fit provided by this assembly is essential for the engine’s operational safety and longevity.

Importance of the 3939915

The 3939915 is designed to withstand the high pressures and stresses encountered in engine operations. Its robust construction ensures that it can maintain a tight seal over the engine’s lifespan, which is critical for both fuel efficiency and system reliability.

By using this part, engine operators can be confident that their systems are secure and that there will be no unexpected failures due to leaks or disconnections. This component is a testament to Cummins’ commitment to quality and durability in their engine components.

Role of the 3939915 in Engine Systems

The 3939915 is an essential component in the integration and functionality of various engine systems. This assembly is primarily utilized in the fuel delivery system, where it plays a significant role in ensuring the secure and efficient transfer of fuel from the fuel filter to the engine.

When fitting the 3939915 into the engine system, it is typically connected to the fuel filter assembly kit. This connection is vital for maintaining the integrity of the fuel line, as it allows for the precise and leak-free transfer of fuel. The assembly is designed to withstand the pressures and temperatures associated with fuel delivery, ensuring consistent performance.

In the context of plumbing within the engine system, the 3939915 acts as a critical junction point. It facilitates the connection between different sections of the fuel line, allowing for flexibility and ease of maintenance. This is particularly important in systems where components may need to be frequently inspected or replaced.

Furthermore, the integration of the 3939915 with the fuel filter is noteworthy. The fuel filter plays a role in removing impurities from the fuel before it reaches the engine. The secure connection provided by the 3939915 ensures that the filtered fuel is delivered efficiently, without any risk of contamination or leakage.

Overall, the 3939915 is a key component in the engine system, facilitating the secure and efficient transfer of fuel while ensuring the overall reliability and performance of the engine.

Conclusion

The Cummins 3939915 Banjo Connector Screw Assembly is a critical component in the hydraulic and fuel systems of commercial trucks. Its design and construction ensure reliable performance, efficient fluid transfer, and secure connections. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this component in commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.