3939409

Connecting Rod Cap Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

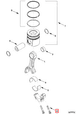

The Cummins 3939409 Connecting Rod Cap Screw is a specialized component designed for use in heavy-duty truck engines. Its purpose is to secure the connecting rod cap to the connecting rod, ensuring the proper functioning of the engine’s piston and crankshaft assembly. This part plays a role in maintaining the integrity and performance of the engine, contributing to its overall efficiency and reliability.

Basic Concepts of Connecting Rod Cap Screws

Connecting rod cap screws are fasteners used to attach the connecting rod cap to the connecting rod in an internal combustion engine. Their primary function is to hold the two halves of the connecting rod together, allowing the rod to pivot smoothly as the piston moves up and down. This movement is crucial for converting the linear motion of the piston into rotational motion of the crankshaft, which powers the vehicle. The reliability and performance of the engine depend significantly on the integrity of these screws, as they must withstand high stresses and dynamic loads 1.

Role of the 3939409 Connecting Rod Cap Screw in Truck Engines

The 3939409 Connecting Rod Cap Screw plays a specific role in the operation of a truck engine by securing the connecting rod cap to the connecting rod. This ensures that the connecting rod can pivot smoothly around the crankshaft journal as the piston moves. The screw must maintain a secure connection under high loads and dynamic conditions, contributing to the engine’s overall performance and longevity. Its interaction with other engine components, such as the crankshaft and piston, is vital for the efficient operation of the engine 2.

Key Features of the 3939409 Connecting Rod Cap Screw

The 3939409 Connecting Rod Cap Screw is characterized by several key features that enhance its performance and durability. It is typically made from high-strength steel, which provides the necessary tensile strength to withstand the high loads encountered in heavy-duty truck engines. The screw’s design specifications, including its thread pitch and length, are optimized for the specific application, ensuring a secure and reliable connection. Additionally, the screw may feature unique characteristics such as a special coating to resist corrosion or a design that facilitates easy installation and removal 3.

Benefits of Using the 3939409 Connecting Rod Cap Screw

Using the 3939409 Connecting Rod Cap Screw offers several benefits. Its high-strength material and precise design contribute to improved engine efficiency by ensuring a secure and reliable connection between the connecting rod and its cap. This can lead to enhanced engine performance and reliability, reducing the likelihood of engine failures. Additionally, the durability of the screw can result in potential cost savings over time by minimizing the need for frequent replacements and repairs 4.

Troubleshooting and Maintenance Tips

To ensure the optimal performance and longevity of the 3939409 Connecting Rod Cap Screw, it is important to address common issues promptly. Regular inspections for signs of wear, corrosion, or damage can help identify potential problems early. Maintenance tips include ensuring proper torque during installation to avoid over-tightening or under-tightening, which can lead to screw failure. Additionally, keeping the engine clean and free of contaminants can help prevent corrosion and extend the life of the screw.

Installation Guidelines

Proper installation of the 3939409 Connecting Rod Cap Screw is critical for its performance and longevity. Step-by-step instructions should be followed to ensure a secure and reliable connection. This includes cleaning the mating surfaces of the connecting rod and cap to remove any debris or contaminants. The screw should be installed using the specified torque settings to ensure it is tightened to the correct level without over-tightening, which can cause damage. Special considerations during installation may include using a torque wrench to achieve the precise torque specification and verifying the alignment of the connecting rod and cap to prevent uneven loading.

Common Failure Modes and Prevention

Connecting rod cap screws can fail due to various modes, including fatigue, corrosion, and improper installation. Fatigue can occur from repeated cyclic loading, while corrosion may result from exposure to moisture or chemicals. Improper installation, such as over-tightening or under-tightening, can also lead to failure. Preventive measures include using high-quality screws designed for the application, following proper installation procedures, and conducting regular inspections to detect and address issues early.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the heavy-duty truck industry for producing reliable and high-performance engines. The company’s commitment to innovation and quality is reflected in its product offerings, which are designed to meet the demanding requirements of heavy-duty applications. The 3939409 Connecting Rod Cap Screw is part of Cummins’ extensive lineup of components that contribute to the efficiency and reliability of their engines.

Cummins Connecting Rod Cap Screw (Part 3939409) in Engine Applications

The Cummins Connecting Rod Cap Screw, identified by part number 3939409, is a critical component in ensuring the structural integrity and operational efficiency of various Cummins engines. This part is designed to secure the connecting rod cap to the connecting rod, thereby maintaining the alignment and stability of the piston assembly.

B4.5 Engine Group

In the B4.5 engine series, the 3939409 screw is integral to the engine’s performance. The B4.5 engines are known for their robust design and reliability, often used in heavy-duty applications. The connecting rod cap screw’s role in this engine series is to withstand high levels of stress and torque, ensuring that the connecting rod remains securely fastened to the crankshaft. This is crucial for the smooth operation of the engine and for preventing any potential failure that could lead to catastrophic engine damage.

The precision engineering of the 3939409 screw ensures that it fits perfectly with the B4.5 engine’s specifications, providing a reliable connection that can endure the demanding conditions of heavy-duty use. The screw’s material and design are optimized to handle the specific loads and stresses encountered in these engines, making it a vital part of the engine’s overall durability and performance.

Role of Part 3939409 Connecting Rod Cap Screw in Engine Systems

The 3939409 Connecting Rod Cap Screw is an essential component in the assembly and functionality of engine systems. Its primary role is to secure the connecting rod cap to the connecting rod, ensuring a stable and reliable connection between the crankshaft and the piston. This secure attachment is vital for the efficient transfer of power from the piston’s linear motion to the crankshaft’s rotational motion.

In the context of engine performance, the 3939409 screw contributes to maintaining the precise alignment and balance of the connecting rod. This alignment is necessary for smooth engine operation, reducing vibrations and wear on engine components. The screw’s torque specification is carefully calibrated to withstand the high stresses and dynamic loads experienced during engine operation, ensuring durability and reliability.

Furthermore, the integrity of the connecting rod cap screw affects the overall performance of the injector system. A secure connection allows for consistent and precise fuel injection timing, which is crucial for optimal combustion efficiency and engine performance. Any deviation in the screw’s tightness can lead to misalignment, affecting the injector’s performance and potentially leading to inefficient fuel consumption and increased emissions.

Conclusion

In summary, the 3939409 Connecting Rod Cap Screw plays a significant role in maintaining the structural integrity and performance of engine components, ensuring smooth operation and efficient power transfer within the engine system. Its high-strength material, precise design, and proper installation are critical for the reliability and efficiency of heavy-duty truck engines.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.