3931061

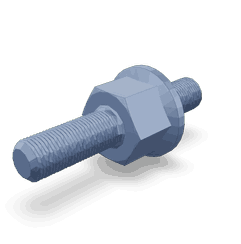

Studded Flange Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw Part #3931061 by Cummins is a specialized fastener designed for heavy-duty truck applications. Cummins, a renowned manufacturer in the automotive industry, produces this component to meet the demanding requirements of truck mechanics and fleet operators. This screw plays a role in ensuring the structural integrity and operational efficiency of various truck components.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud with a flange at one end and a cap screw at the other. The flange provides a larger surface area for distribution of clamping force, which enhances the screw’s ability to secure components firmly. In a truck’s mechanical system, these screws are used to connect and secure various parts, ensuring they remain in place under significant stress and vibration 1.

Purpose and Role

The 3931061 Studded Flange Cap Screw is designed to secure and maintain the structural integrity of various truck components. It is commonly used in applications where high clamping force and resistance to vibration are required. By providing a secure connection, this screw helps to ensure that critical components remain firmly in place, contributing to the overall safety and reliability of the truck 2.

Key Features

The 3931061 Studded Flange Cap Screw boasts several key features that enhance its performance and durability. It is made from high-strength materials, ensuring it can withstand the rigors of heavy-duty truck applications. The design includes a flange that distributes clamping force more effectively, reducing the risk of component failure. Additionally, the screw is engineered to resist corrosion, extending its service life in various operating environments 3.

Benefits

The use of the 3931061 Studded Flange Cap Screw offers several benefits to fleet operators. Its high-strength material composition and robust design contribute to improved reliability and safety. The screw’s ability to resist corrosion and vibration ensures long-term performance, potentially reducing maintenance costs and downtime. Furthermore, the secure connections provided by this screw help to enhance the overall efficiency and durability of truck components.

Installation and Usage

Proper installation of the 3931061 Studded Flange Cap Screw is crucial for optimal performance. It is recommended to follow manufacturer guidelines for torque settings to ensure the screw is tightened to the appropriate level without over-tightening, which could lead to damage. Best practices include using the correct tools and ensuring that all mating surfaces are clean and free of debris to facilitate a secure connection.

Troubleshooting and Maintenance

Common issues with the 3931061 Studded Flange Cap Screw may include corrosion or loosening over time. Regular inspection and maintenance can help identify and address these issues promptly. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can help prolong the screw’s lifespan. Ensuring that the screw is properly torqued during installation and re-tightening it periodically can prevent loosening.

Manufacturer - Cummins

Cummins is a well-established manufacturer with a strong reputation in the automotive industry. The company has a history of innovation and commitment to quality, producing a wide range of automotive components that meet the highest standards. Cummins’ dedication to research and development ensures that their products, including the 3931061 Studded Flange Cap Screw, are designed to deliver reliable performance and durability in demanding applications.

Studded Flange Cap Screw 3931061 in Cummins Engines

The Studded Flange Cap Screw 3931061, manufactured by Cummins, is a component in various Cummins engine models. This part is used for securing flanges and ensuring a tight seal, which is vital for the engine’s performance and longevity.

6C8.3 and B5.6 CM2670 B152B

The 6C8.3 and B5.6 CM2670 B152B engines utilize the 3931061 stud for securing various flanges, including those on the exhaust manifold and turbocharger. This ensures that the connections remain tight and leak-free, which is crucial for maintaining optimal engine performance.

B6.7 CM2350 B135B and C GAS PLUS CM556

In the B6.7 CM2350 B135B and C GAS PLUS CM556 engines, the 3931061 stud is used to secure flanges on the intake and exhaust systems. These engines benefit from the reliability of the stud, which helps maintain the integrity of the connections under high-stress conditions.

D4.0 CM2620 D103B and F4.5 CM2620 F139B

The D4.0 CM2620 D103B and F4.5 CM2620 F139B engines also incorporate the 3931061 stud in their design. This part is crucial for securing flanges on the turbocharger and exhaust systems, ensuring that these components remain securely attached and function as intended.

G8.3 and G8.3 CM558

The G8.3 and G8.3 CM558 engines use the 3931061 stud for securing flanges on the intake and exhaust manifolds. This helps maintain the structural integrity of these components, which is essential for the engine’s overall performance.

GTA8.3 CM558 and ISB (Chrysler)

The GTA8.3 CM558 and ISB (Chrysler) engines utilize the 3931061 stud for securing flanges on the intake and exhaust systems. This ensures that the connections remain tight and secure, which is vital for the engine’s performance and reliability.

ISB CM2150, ISB CM850, and ISB5.9 CM2880 B149

The ISB CM2150, ISB CM850, and ISB5.9 CM2880 B149 engines incorporate the 3931061 stud for securing flanges on the intake and exhaust manifolds. This helps maintain the structural integrity of these components, which is essential for the engine’s overall performance.

ISB6.7 CM2250, ISB6.7 CM2350 B101, and ISB6.7 G CM2180 B118

The ISB6.7 CM2250, ISB6.7 CM2350 B101, and ISB6.7 G CM2180 B118 engines use the 3931061 stud for securing flanges on the intake and exhaust systems. This ensures that the connections remain tight and secure, which is vital for the engine’s performance and reliability.

ISC CM850 and ISC8.3 CM2250

The ISC CM850 and ISC8.3 CM2250 engines utilize the 3931061 stud for securing flanges on the intake and exhaust manifolds. This helps maintain the structural integrity of these components, which is essential for the engine’s overall performance.

ISG12 G CMOH6.0 G111

The ISG12 G CMOH6.0 G111 engine incorporates the 3931061 stud for securing flanges on the intake and exhaust systems. This ensures that the connections remain tight and secure, which is vital for the engine’s performance and reliability.

ISL CM2150, ISL G CM2180, and ISL9 CM2150 SN

The ISL CM2150, ISL G CM2180, and ISL9 CM2150 SN engines use the 3931061 stud for securing flanges on the intake and exhaust manifolds. This helps maintain the structural integrity of these components, which is essential for the engine’s overall performance.

ISL9 CM2250 and ISL9.5 CM2880 L138

The ISL9 CM2250 and ISL9.5 CM2880 L138 engines incorporate the 3931061 stud for securing flanges on the intake and exhaust systems. This ensures that the connections remain tight and secure, which is vital for the engine’s performance and reliability.

ISM CM876

The ISM CM876 engine utilizes the 3931061 stud for securing flanges on the intake and exhaust manifolds. This helps maintain the structural integrity of these components, which is essential for the engine’s overall performance.

Role of Part 3931061 Studded Flange Cap Screw in Engine Systems

The Part 3931061 Studded Flange Cap Screw is integral to the assembly and secure fitting of various engine components, ensuring the structural integrity and efficient operation of the engine system.

In the aftercooler system, this screw is used to fasten the aftercooler to its mounting brackets, ensuring a secure and leak-free connection that is vital for efficient cooling of compressed air. Similarly, in the aftercooler mounting, it plays a role in securing the aftercooler to the engine frame, contributing to the stability and durability of the setup.

For the air intake connection and air intake manifold, the Part 3931061 screw is employed to ensure a tight seal between the manifold and the engine block, preventing air leaks that could affect engine performance. In the air intake manifold mounting, it secures the manifold to the engine, ensuring it remains in the correct position under varying operational conditions.

In the camshaft assembly, this screw is used to attach various components to the camshaft housing, ensuring precise alignment and operation of the camshaft. The crankcase breather system utilizes this screw to secure the breather housing, allowing for effective ventilation of the crankcase while preventing oil leaks.

For the cylinder block cover, the Part 3931061 screw ensures a secure fit, protecting the internal components of the engine and maintaining the integrity of the engine block. In the engine oil cooler and oil cooler systems, it is used to attach the cooler to its mounting points, ensuring efficient heat exchange and maintaining optimal oil temperature.

The exhaust recirculation system and exhaust recirculation air plumbing use this screw to secure components, ensuring a leak-free path for recirculated exhaust gases, which helps in reducing emissions. In the front gear cover, it is used to fasten the cover to the engine, protecting the front gears and ensuring they operate smoothly.

For the fuel filter, the Part 3931061 screw secures the filter housing, ensuring it remains in place and functions correctly to provide clean fuel to the engine. In the injector plumbing, it is used to secure fittings and connections, ensuring a reliable fuel delivery system.

In the long block assembly, this screw is utilized in various points to ensure all components are securely fastened, contributing to the overall structural integrity of the engine. The noise reduction device system uses it to attach the device to the engine, ensuring effective noise reduction.

For the oil level gauge, the screw secures the gauge to the engine, allowing for accurate monitoring of oil levels. In the oil pan, it is used to attach the pan to the engine block, ensuring a secure and leak-free oil reservoir.

In the turbocharger arrangement and turbocharger plumbing, the Part 3931061 screw is essential for securing turbocharger components and plumbing, ensuring efficient operation and durability. Finally, in the water pump system, it is used to attach the pump to the engine, ensuring reliable coolant circulation.

Conclusion

The 3931061 Studded Flange Cap Screw by Cummins is a critical component in heavy-duty truck applications, providing secure and reliable connections for various engine components. Its robust design, high-strength materials, and corrosion resistance make it an essential part for maintaining the structural integrity and operational efficiency of truck engines. Proper installation and maintenance of this screw are crucial for ensuring long-term performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.