This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

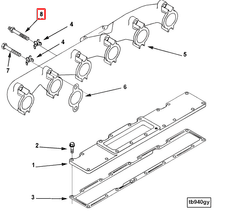

The Studded Hexagon Cap Screw, Part #3929538 by Cummins, is a specialized fastener designed for heavy-duty applications. Cummins, a renowned manufacturer in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty trucks. This part is integral to ensuring the reliability and performance of truck components, highlighting Cummins’ commitment to quality and innovation.

Basic Concepts of Studded Hexagon Cap Screws

A studded hexagon cap screw is a type of fastener characterized by a hexagonal head and a threaded shank that extends beyond the nut or tapped hole it secures. This design allows for efficient torque application and removal using a wrench or socket, making it suitable for various fastening applications. The studded design ensures that the screw remains in place even under significant stress, providing a secure and durable connection 1.

Role of the 3929538 Studded Hexagon Cap Screw in Truck Operation

The 3929538 Studded Hexagon Cap Screw plays a significant role in the assembly and maintenance of heavy-duty trucks. It is used in various truck components, including engine mounts, transmission housings, and chassis assemblies. By providing a strong and reliable fastening solution, this screw helps maintain the structural integrity and performance of critical truck systems 2.

Key Features

The 3929538 Studded Hexagon Cap Screw boasts several key features that enhance its functionality and durability. It is made from high-strength materials, ensuring resistance to wear and corrosion. The screw features a coarse thread type, which allows for quick and secure fastening. Additionally, the hexagonal head design enables easy torque application, reducing the risk of stripping or rounding during installation or removal.

Benefits

Using the 3929538 Studded Hexagon Cap Screw offers several advantages. Its durable material composition and robust design contribute to long-lasting performance, even in harsh operating conditions. The screw’s resistance to vibration helps maintain a secure connection over time, reducing the need for frequent re-tightening. Furthermore, the ease of installation provided by the hexagonal head design simplifies maintenance procedures, saving time and effort.

Installation Process

Proper installation of the 3929538 Studded Hexagon Cap Screw is crucial for optimal performance and longevity. Begin by ensuring the mating surfaces are clean and free of debris. Apply a suitable thread lubricant to the screw threads to reduce friction and prevent galling. Insert the screw into the tapped hole or nut and use a wrench or socket to tighten it to the recommended torque specification. Avoid over-tightening, as this can lead to thread damage or component failure.

Maintenance Tips

Regular maintenance of the 3929538 Studded Hexagon Cap Screw is essential to ensure continued performance and reliability. Inspect the screw periodically for signs of wear, corrosion, or damage. Check the torque settings to ensure the screw remains securely fastened. If any issues are detected, address them promptly by re-tightening or replacing the screw as necessary. Following these maintenance practices will help extend the lifespan of the fastener and maintain the integrity of the truck’s components.

Troubleshooting Common Issues

Common problems associated with studded hexagon cap screws include loosening due to vibration, corrosion, and thread damage. To address these issues, first, ensure the screw is properly torqued during installation. Use anti-seize compound to prevent corrosion and facilitate easier removal in the future. If thread damage occurs, replace the screw and inspect the mating threads for damage. Addressing these issues promptly will help maintain the screw’s performance and reliability.

Safety Considerations

When working with studded hexagon cap screws, it is important to follow safety precautions and best practices to prevent accidents and ensure proper handling. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Use the correct tools and techniques for installation and removal to avoid damaging the screw or surrounding components. Additionally, be mindful of the torque settings to prevent over-tightening, which can lead to component failure.

Cummins Overview

Cummins is a leading manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. The company’s dedication to research and development ensures that its products, including the 3929538 Studded Hexagon Cap Screw, meet the rigorous demands of heavy-duty applications.

Studded Hexagon Cap Screw 3929538 in Cummins Engines

The Studded Hexagon Cap Screw 3929538, manufactured by Cummins, is a critical component in several of their engine models. This part is essential for securing various engine parts and ensuring the structural integrity of the engine assembly.

6C8.3 and C8.3 G Engines

In the 6C8.3 and C8.3 G engines, the 3929538 screw is used to fasten components that require high strength and durability. These engines, known for their robust performance, benefit from the reliability of this screw in maintaining the alignment and stability of critical engine parts.

ISC CM554 and ISL CM554 Engines

For the ISC CM554 and ISL CM554 engines, the 3929538 screw plays a pivotal role in securing the engine’s internal and external components. These engines, designed for heavy-duty applications, rely on this screw to withstand the stresses of continuous operation, ensuring longevity and performance.

QSC8.3 CM554 and QSL9 CM554 Engines

In the QSC8.3 CM554 and QSL9 CM554 engines, the 3929538 screw is utilized in various applications where high-strength fastening is necessary. These engines, often used in demanding environments, depend on this screw to maintain the precise alignment and secure fit of their components, contributing to the overall efficiency and durability of the engine.

Role of Part 3929538 Studded Hexagon Cap Screw in Engine Systems

The Part 3929538 Studded Hexagon Cap Screw is integral in the assembly and operation of various engine components, ensuring secure and reliable connections.

Turbocharger Arrangement

In turbocharger systems, the Part 3929538 screw is often used to fasten the turbocharger to its mounting bracket. This secure attachment is essential for maintaining the turbocharger’s position and alignment, which directly affects its performance and efficiency. The screw’s studded design provides additional stability, reducing the risk of loosening under high-stress conditions typical in turbocharger operation.

Turbocharger Location

At the turbocharger location, the Part 3929538 screw plays a significant role in connecting the turbocharger to the engine’s exhaust manifold. This connection is vital for the proper flow of exhaust gases, which drive the turbocharger’s turbine. The screw ensures a tight seal, preventing leaks that could compromise turbocharger efficiency and engine performance. Additionally, it helps in dissipating heat from the turbocharger housing to the engine block, contributing to the overall thermal management of the engine system.

General Engine Assembly

Beyond specific components like the turbocharger, the Part 3929538 screw is widely used throughout engine assemblies to secure various parts. Its hexagonal head allows for easy tightening and loosening with standard tools, making it a preferred choice for applications where frequent maintenance or adjustments are necessary. The studded feature enhances the screw’s grip, providing a more secure fastening solution in dynamic engine environments.

Conclusion

In summary, the Part 3929538 Studded Hexagon Cap Screw is a versatile and reliable component in engine systems, facilitating secure connections and contributing to the overall performance and durability of the engine. Its robust design, ease of installation, and resistance to wear and corrosion make it an essential part in the assembly and maintenance of heavy-duty engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.