This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3924444 Ball Screw is a precision-engineered component designed for use in commercial trucks. Manufactured by Cummins Inc., a leader in the diesel engine and power generation industries, this part plays a significant role in the mechanical systems of trucks, contributing to their overall performance and efficiency 1.

Basic Concepts of Ball Screws

A ball screw is a mechanical device that converts rotational motion into linear motion through the use of a helical ball bearing. It consists of a screw shaft, a nut containing ball bearings, and a recirculation system that returns the balls to the start of the circuit. Ball screws are widely used in various mechanical systems due to their high efficiency, precision, and ability to handle heavy loads with minimal friction 2.

Role of the 3924444 Ball Screw in Truck Operation

The Cummins 3924444 Ball Screw is integral to the operation of commercial trucks, particularly in systems requiring precise linear motion. It is commonly used in steering mechanisms, suspension systems, and other components where accurate movement and load handling are crucial. The ball screw works in conjunction with other mechanical parts to ensure smooth and reliable operation of the truck 3.

Key Features

The Cummins 3924444 Ball Screw is characterized by several key features that enhance its performance. It is constructed from high-quality materials to ensure durability and longevity. The design incorporates precision-machined components to provide accurate and reliable linear motion. Additionally, the ball screw is engineered to handle significant loads while maintaining efficiency and reducing wear 4.

Benefits of Using the 3924444 Ball Screw

Utilizing the Cummins 3924444 Ball Screw in truck operations offers several advantages. Its high efficiency reduces energy consumption, leading to improved fuel economy. The precision of the ball screw ensures accurate and consistent performance, enhancing the overall reliability of the truck. Furthermore, its robust construction contributes to durability, reducing the need for frequent replacements and maintenance 5.

Installation and Integration

Installing the Cummins 3924444 Ball Screw requires careful attention to ensure proper integration into the truck’s system. It is important to follow manufacturer guidelines for installation, which may include aligning the screw with other components, securing it in place, and ensuring proper lubrication. Consideration should be given to the specific requirements of the truck’s mechanical system to ensure optimal performance 6.

Troubleshooting Common Issues

Ball screws, including the Cummins 3924444, may encounter issues such as increased friction, noise, or reduced performance over time. These problems can often be traced to inadequate lubrication, misalignment, or wear. Troubleshooting steps may involve inspecting the ball screw for signs of damage, ensuring proper lubrication, and checking for correct alignment with other components 7.

Maintenance Practices

To ensure the longevity and optimal performance of the Cummins 3924444 Ball Screw, regular maintenance is recommended. This includes periodic lubrication to reduce friction and wear, inspection for signs of damage or misalignment, and replacement of worn components as necessary. Adhering to a maintenance schedule can help prevent issues and extend the lifespan of the ball screw 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles 9.

Ball Screw 3924444 in Cummins Engines

The Ball Screw 3924444, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the engine’s operation, ensuring precise movement and control within the engine’s mechanisms 10.

Application in Specific Engine Models

-

6B5.9 Engine Series

In the 6B5.9 engine series, the Ball Screw 3924444 plays a pivotal role in the engine’s performance. It is typically used in the engine’s valve train system, where it facilitates the smooth and accurate opening and closing of the engine’s valves. This precision is essential for maintaining optimal engine efficiency and performance 11.

-

Grouped Engine Models

Cummins engines often share components across different models to ensure consistency and reliability. The Ball Screw 3924444 is one such part that is utilized across various engine groups within the Cummins lineup. Its application in these grouped engines ensures that the same high standards of performance and durability are maintained across different engine models 12.

Importance of the Ball Screw

The Ball Screw 3924444 is designed to provide a low-friction, high-precision mechanism for converting rotational motion into linear motion. This capability is crucial in engines where precise control of valve timing and lift is necessary. The use of ball screws in Cummins engines helps in reducing wear and tear, thereby extending the engine’s lifespan and maintaining its performance over time 13.

Integration and Functionality

In Cummins engines, the Ball Screw 3924444 is integrated into the engine’s valve train system. It works in conjunction with other components to ensure that the engine’s valves operate with the exact timing and lift required for efficient combustion. This integration is vital for the engine’s overall performance, as any deviation in valve operation can lead to inefficiencies and potential engine damage 14.

Reliability and Performance

Cummins is known for its commitment to quality and reliability, and the Ball Screw 3924444 is no exception. This part is engineered to withstand the rigorous demands of engine operation, providing consistent performance even under high stress and varying conditions. The use of high-quality materials and precision manufacturing ensures that the ball screw operates smoothly and reliably, contributing to the engine’s overall durability and efficiency 15.

Role of Part 3924444 Ball Screw in Engine Systems

The 3924444 Ball Screw is an integral component in the precise and efficient operation of various engine systems. Its role is to facilitate smooth and accurate linear motion, which is essential for the proper functioning of several key components 16.

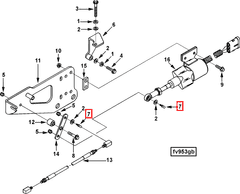

Fuel Shutoff Valve Lever

In the fuel shutoff valve lever system, the 3924444 Ball Screw ensures that the lever moves with minimal friction and maximum precision. This is vital for the accurate control of fuel flow, which directly impacts engine performance and efficiency. The ball screw’s ability to convert rotary motion into linear motion allows for fine adjustments to the valve lever, ensuring that the fuel shutoff is both swift and precise 17.

Throttle Mechanism

Within the throttle mechanism, the 3924444 Ball Screw plays a significant role in modulating the airflow into the engine. By providing a smooth and consistent linear motion, it allows for precise control over the throttle position. This precision is essential for maintaining optimal engine performance across various operating conditions, from idle to full throttle 18.

Solenoid Assembly Bracket

In the solenoid assembly bracket, the 3924444 Ball Screw is used to translate the electrical signals from the solenoid into mechanical motion. This conversion is critical for the accurate operation of components such as the fuel shutoff valve. The ball screw ensures that the solenoid’s movements are transmitted efficiently and without loss of precision, contributing to the reliable operation of the engine 19.

Valve Operation

For valve operation, the 3924444 Ball Screw is employed to ensure that the valve opens and closes with the required force and accuracy. This is particularly important in high-performance engines where valve timing and lift must be meticulously controlled to achieve maximum efficiency and power output. The ball screw’s design minimizes backlash and wear, ensuring consistent valve operation over time 20.

Fuel Shutoff System

In the fuel shutoff system, the 3924444 Ball Screw is instrumental in providing the necessary linear motion for the shutoff mechanism. Its high precision and low friction characteristics ensure that the fuel shutoff occurs exactly when needed, without any delay or inconsistency. This is essential for both the safety and performance of the engine, as it prevents fuel leakage and ensures a clean shutoff during engine shutdown or emergency situations 21.

Conclusion

The Cummins 3924444 Ball Screw is a critical component in the operation of commercial trucks and Cummins engines. Its precision, efficiency, and durability contribute to the overall performance and reliability of these vehicles. Proper installation, maintenance, and troubleshooting are essential to ensure the optimal functioning of this part in various engine systems.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579683, Engine: B6.7 CM2350 B157C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.