This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

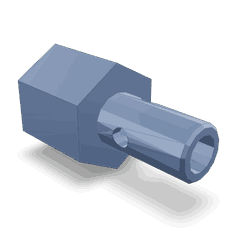

The 3914037 Banjo Connector Screw, manufactured by Cummins, is a component used in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts designed to enhance the efficiency and reliability of truck systems. This Cummins part is integral to the fluid systems within trucks, ensuring the smooth operation of hydraulic or fuel lines.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with a banjo fitting attached, which allows for the secure connection of fluid lines. In the context of a truck’s hydraulic or fuel system, this part facilitates the transfer of fluids under pressure, ensuring that systems operate efficiently and without leaks 1.

Purpose of the 3914037 Banjo Connector Screw

The 3914037 Banjo Connector Screw serves a specific role in truck operations by connecting hydraulic or fuel lines to critical components. Its design allows for a secure and leak-proof connection, which is vital for maintaining system integrity and performance. This part ensures that fluids are delivered consistently and under the correct pressure, contributing to the overall efficiency of the truck’s systems.

Key Features

The 3914037 Banjo Connector Screw boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials, typically steel or stainless steel, which provide resistance to corrosion and wear. The thread type is designed to ensure a tight and secure fit, while the overall design of the banjo fitting allows for easy connection and disconnection of fluid lines. These features contribute to the part’s reliability and longevity in demanding truck environments.

Benefits

Using the 3914037 Banjo Connector Screw offers several benefits. Its design promotes improved sealing, reducing the risk of leaks that can compromise system performance. The ease of installation is another advantage, as the fitting allows for quick and secure connections without the need for complex tools. Additionally, its resistance to corrosion and high pressures ensures that it can withstand the rigors of commercial truck operations, providing reliable performance over time.

Installation Process

Proper installation of the 3914037 Banjo Connector Screw involves several steps to ensure a secure fit. Begin by cleaning the connection points to remove any debris or contaminants. Next, apply a compatible thread sealant to the threads of the screw to enhance the seal. Using the appropriate tools, screw the banjo fitting into place, ensuring that it is tightened to the manufacturer’s specified torque. Finally, check the connection for leaks by pressurizing the system and inspecting the fitting.

Troubleshooting Common Issues

Common issues with Banjo Connector Screws include leaks and connection failures. If a leak is detected, the first step is to ensure that the fitting is tightened correctly. If the leak persists, inspect the fitting and connection points for damage or wear. In some cases, replacing the gasket or O-ring within the banjo fitting may resolve the issue. For connection failures, verify that the threads are clean and free of debris, and consider reapplying thread sealant if necessary.

Maintenance Tips

To ensure the longevity and reliable performance of the 3914037 Banjo Connector Screw, regular maintenance is recommended. Periodically inspect the fitting for signs of wear or corrosion, and clean the connection points to remove any buildup. If the fitting shows signs of damage, it should be replaced to prevent potential leaks or failures. Additionally, following the manufacturer’s guidelines for torque specifications during installation will help maintain a secure connection.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to excellence is evident in its continued investment in research and development, ensuring that its products remain at the forefront of technology and reliability.

Engine Compatibility with Part 3914037

The Banjo Connector Screw part number 3914037, manufactured by Cummins, is a crucial component in various engine systems. This part is designed to ensure secure connections in hydraulic and fuel lines, providing a reliable seal to prevent leaks.

6C8.3 Engine

In the 6C8.3 engine, the Banjo Connector Screw is integral to maintaining the integrity of the fuel and hydraulic systems. It is used in several applications within the engine, ensuring that connections remain tight and secure under operational conditions. The precision of this part is essential for the overall performance and safety of the engine.

Group Compatibility

The Banjo Connector Screw part number 3914037 is also compatible with other Cummins engines that share similar design and operational requirements. These engines benefit from the robust sealing and secure fastening provided by this component, ensuring consistent performance and reliability.

The part’s design allows it to fit seamlessly into the engine’s architecture, providing a dependable connection point for critical lines. This compatibility extends to various engine models that rely on the same type of connection for their hydraulic and fuel systems.

Role of Part 3914037 Banjo Connector Screw in Engine Systems

In the context of engine systems, the Banjo Connector Screw, identified by part number 3914037, serves as a vital component in ensuring the secure and efficient transfer of fluids. Specifically, this component is integral to the operation of the lift pump and the fuel transfer system.

Integration with Lift Pump

The lift pump is responsible for drawing fuel from the tank and delivering it to the main fuel pump at a higher pressure. The Banjo Connector Screw plays a significant role here by providing a reliable connection point between the lift pump and the fuel lines. This ensures that the fuel is transferred without leaks, maintaining the integrity of the fuel system and preventing any potential fuel loss or contamination.

Functionality in Fuel Transfer

In the fuel transfer system, the Banjo Connector Screw is used to connect various components such as the fuel filter, fuel lines, and injectors. Its design allows for a secure fit that withstands the pressure fluctuations typical in fuel systems. This connection is essential for maintaining a consistent fuel flow, which is necessary for the engine to operate efficiently. The screw’s ability to create a tight seal helps in preventing air from entering the fuel lines, which could otherwise lead to engine performance issues.

Ensuring System Integrity

By providing a robust and leak-proof connection, the Banjo Connector Screw contributes to the overall reliability of the engine’s fuel system. Its role in securing connections between critical components like the lift pump and fuel transfer lines ensures that the engine receives a steady supply of fuel, which is fundamental for consistent performance and longevity of the engine.

Conclusion

The 3914037 Banjo Connector Screw is a critical component in the fluid systems of commercial trucks, ensuring secure and efficient transfer of fluids in hydraulic and fuel lines. Its robust design, ease of installation, and resistance to corrosion make it a reliable choice for maintaining system integrity and performance. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this Cummins part in demanding truck environments.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.