3864166

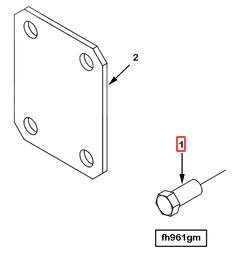

Hexagon Flange Head Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 3864166, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This screw is integral to the assembly and maintenance of various truck components, ensuring the structural integrity and operational efficiency of commercial vehicles.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient torque application using standard tools, while the flange provides a larger bearing surface that helps distribute loads more evenly and prevents the screw from sinking into the material. Within mechanical systems, these screws are used to secure components together, ensuring stability and alignment 1.

Purpose and Role in Truck Operation

This Cummins part serves a specific purpose in commercial truck operations. It is utilized in various applications across the truck, including but not limited to, engine components, chassis assemblies, and body panels. By securing these parts, the screw contributes to the overall stability and durability of the truck. It plays a role in maintaining the alignment and integrity of critical systems, thereby supporting the truck’s performance and longevity 2.

Key Features

The 3864166 boasts several key features that enhance its functionality and durability. Its hexagonal head design allows for straightforward and secure fastening using common tools. The flange beneath the head provides an increased bearing surface, which aids in distributing loads more effectively and reduces the risk of the screw pulling through the material. Additionally, the screw is crafted from high-quality materials, ensuring it can withstand the rigors of commercial truck use, including exposure to varying weather conditions and mechanical stresses 3.

Benefits

Utilizing the 3864166 offers several advantages. The design of the screw enhances stability in fastening applications, reducing the likelihood of components becoming loose over time. The flange feature contributes to improved load distribution, which can help prevent damage to the material being fastened. Furthermore, the high-quality material used in its construction ensures durability and resistance to corrosion, making it a reliable choice for commercial truck applications.

Installation and Usage

Proper installation of the 3864166 is vital to ensure optimal performance and longevity. It is recommended to use the appropriate torque settings when tightening the screw to avoid over-tightening, which can lead to damage, or under-tightening, which can compromise the security of the fastening. Additionally, ensuring that the surfaces being fastened are clean and free from debris will help achieve a secure and lasting connection.

Troubleshooting and Maintenance

Common issues associated with Hexagon Flange Head Cap Screws include loosening over time and corrosion. Regular inspections can help identify these problems early. If a screw appears loose, it should be re-tightened to the manufacturer’s specified torque settings. In cases of corrosion, particularly in outdoor or harsh environments, applying a corrosion-resistant coating or replacing the screw may be necessary to maintain reliable operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and customer satisfaction in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to innovation and excellence has made it a trusted name among truck manufacturers and operators worldwide.

Cummins Engine Compatibility with Part 3864166

The Cummins part 3864166, a Hexagon Flange Head Cap Screw, is designed to be compatible with a range of Cummins engines, ensuring secure fastening and reliable performance. This part is particularly suited for the following engines:

B3.3

The B3.3 engine benefits from the robust design of the 3864166 screw, providing essential fastening in various applications. Its precision engineering ensures that the screw fits seamlessly, contributing to the engine’s overall stability and durability.

QSB3.3 CM2150 and QSB3.3 CM2250 EC

For the QSB3.3 CM2150 and QSB3.3 CM2250 EC engines, the 3864166 Hexagon Flange Head Cap Screw is a critical component. These engines, known for their reliability and performance, require high-quality fasteners to maintain their structural integrity. The screw’s design allows for precise alignment and secure fastening, which is crucial for the operation of these engines.

The compatibility of the 3864166 screw with these engines underscores its versatility and importance in ensuring that the engines function optimally. The screw’s ability to withstand the stresses and demands of engine operation makes it an indispensable part of the engine’s assembly.

Role of Part 3864166 Hexagon Flange Head Cap Screw in Engine Systems

In the intricate assembly of engine systems, the 3864166 serves as a fundamental fastening component. This screw is integral in securing various engine components, ensuring their stability and proper function.

Engine Control Module (ECM) and Its Mounting

The ECM is the brain of the engine, regulating various functions to optimize performance. The Hexagon Flange Head Cap Screw is employed in the mounting of the ECM, providing a secure attachment to the engine bay. This ensures that the ECM remains firmly in place, unaffected by vibrations or movements, which could otherwise disrupt its sensitive electronic components.

Flywheel Housing and Flywheel Mounting

In the mechanical domain of the engine, the flywheel plays a pivotal role in storing rotational energy. The Hexagon Flange Head Cap Screw is utilized in the mounting of the flywheel housing and the flywheel itself. This secures the flywheel in position, allowing it to interact efficiently with the engine’s crankshaft. The screw’s design ensures a tight and durable connection, vital for the consistent operation of the engine’s power delivery system.

Alternator Mounting

The alternator is responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems. The Hexagon Flange Head Cap Screw is used in the alternator’s mounting process. It ensures that the alternator is securely fastened to the engine, maintaining its alignment and operational efficiency. This is essential for the alternator to function correctly without the risk of detachment or misalignment.

Plumbing and Fuel Filter Connections

In the engine’s fluid systems, including fuel and coolant, the Hexagon Flange Head Cap Screw is used in various plumbing connections. It secures fittings and components, ensuring leak-free and efficient fluid flow. Specifically, in the fuel system, this screw is crucial in mounting the fuel filter, ensuring it is held firmly in place. This is important for the filter’s effectiveness in purifying the fuel before it reaches the engine, contributing to overall engine performance and longevity.

The utilization of the Hexagon Flange Head Cap Screw across these diverse engine components underscores its versatility and importance in maintaining the structural integrity and functional efficiency of the engine system.

Conclusion

The 3864166 Hexagon Flange Head Cap Screw is a vital component in the assembly and maintenance of commercial trucks and engines. Its design, featuring a hexagonal head and a flange, ensures efficient torque application and improved load distribution. The screw’s compatibility with various Cummins engines highlights its versatility and importance in ensuring optimal engine performance. Proper installation and maintenance of this part are crucial for the longevity and reliability of commercial vehicles.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.