This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

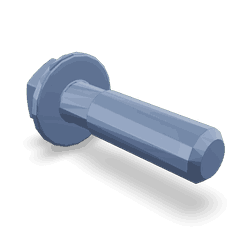

The Hexagonal Flange Head Cap Screw, identified by part number 3864027, is a specialized fastener utilized in commercial trucks. Manufactured by Cummins, a reputable name in the automotive industry, this screw is integral to the mechanical systems of heavy-duty vehicles. Its design and functionality are tailored to meet the demanding requirements of commercial truck operations 1.

Basic Concepts

A Hexagonal Flange Head Cap Screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The flange, a flat, circular plate at the base of the head, distributes the load more evenly across the surface it contacts, reducing the risk of damage to the material being fastened. In a truck’s mechanical system, this screw serves to securely fasten components, ensuring they remain in place under various operational stresses 2.

Role and Purpose

This Cummins part plays a significant role in the operation of a truck by providing a secure fastening solution for various components. Its applications range from attaching engine parts to securing chassis elements. The screw’s design ensures that it can withstand the vibrations and stresses inherent in truck operations, maintaining the integrity of the fastened components 3.

Key Features

The 3864027 boasts several key features that enhance its performance and durability. Its hexagonal flange head design allows for easy and precise tightening. The screw is typically made from high-strength materials, ensuring it can endure the harsh conditions encountered in commercial truck environments. Additionally, the flange head provides a larger surface area for load distribution, reducing the likelihood of stripping or damage to the fastened material.

Benefits

Utilizing this part offers several benefits. The screw’s design contributes to improved fastening security, minimizing the risk of components becoming loose during operation. Its resistance to vibration ensures that fastenings remain tight, even under the dynamic conditions experienced by commercial trucks. Furthermore, the screw’s durability in harsh operating conditions contributes to the longevity of the fastened components, reducing the need for frequent replacements.

Installation Process

Proper installation of the 3864027 is vital for optimal performance and safety. The installation process should begin with ensuring the surfaces to be fastened are clean and free of debris. The screw should be inserted into the pre-drilled hole and tightened using a wrench or socket, taking care not to over-tighten, which could damage the screw or the material being fastened. It is also important to periodically check the tightness of the screw to ensure it remains secure throughout the truck’s operation.

Troubleshooting and Maintenance

Common issues with the 3864027 may include signs of wear, corrosion, or failure. Regular inspections should be conducted to identify any such issues early. Maintenance tips to prolong the screw’s lifespan include keeping the fastening area clean and free of corrosive substances, and replacing the screw if it shows significant signs of wear or damage. Proper maintenance ensures continued reliable performance and helps prevent unexpected failures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, including the 3864027, which is designed to meet the rigorous demands of commercial truck applications.

Hexagonal Flange Head Cap Screw in Cummins Engines

The Hexagonal Flange Head Cap Screw part number 3864027, manufactured by Cummins, is a critical component in various Cummins engines. This screw is designed to provide a secure fastening solution, ensuring that engine parts remain tightly connected under operational stresses.

QST30 and CM2350 Engines

In the QST30 and CM2350 engines, the 3864027 screw is utilized in several key areas. These engines, known for their reliability and efficiency, often require robust fastening solutions to maintain structural integrity and performance. The screw’s hexagonal flange head allows for easy and precise tightening with a wrench, which is essential for the maintenance and assembly of these engines.

T101 Engine

The T101 engine also incorporates the 3864027 screw in its design. This engine, part of Cummins’ lineup, benefits from the screw’s ability to withstand high torque and pressure, ensuring that components such as engine covers and housings remain securely fastened. The flange head design of the screw provides a larger surface area for the wrench, which is crucial for the assembly and disassembly processes in engine maintenance.

Application in Engine Maintenance

The use of the 3864027 screw in these engines highlights its importance in maintaining the structural and operational integrity of the engine components. Its design ensures that the screw can handle the rigors of engine operation, providing a reliable fastening solution that is essential for the longevity and performance of the engines.

Role of Part 3864027 Hexagonal Flange Head Cap Screw in Engine Systems

Part 3864027, the Hexagonal Flange Head Cap Screw, is integral to the assembly and securement of various engine components. Its design allows for efficient torque application and resistance to loosening, making it suitable for high-stress applications within engine systems.

Engine Control Module Mounting

In the mounting of the Engine Control Module (ECM), the Hexagonal Flange Head Cap Screw ensures a stable and secure attachment to the engine bay. This stability is essential for the ECM to function correctly, as any movement can lead to inaccurate readings and potential engine performance issues.

Heat Shield Mounting

When mounting heat shields, the Hexagonal Flange Head Cap Screw plays a significant role in maintaining the integrity of the shield’s position. Heat shields are critical for protecting nearby components from excessive heat, and secure fastening is necessary to prevent displacement under thermal expansion and contraction.

Exhaust Manifold Plumbing

In the context of exhaust manifold plumbing, these screws are used to secure manifold components and ensure a tight seal. A secure fit is necessary to prevent exhaust leaks, which can lead to performance losses and increased emissions.

Fuel Supply Plumbing

For fuel supply plumbing, the Hexagonal Flange Head Cap Screw is employed to fasten fuel lines and fittings. This ensures that the fuel system remains pressurized and leak-free, which is vital for consistent engine operation and safety.

Turbocharger and Turbocharger Kit

In turbocharger and turbocharger kit assemblies, these screws are often used to secure turbocharger components, such as the turbine housing and compressor cover. The secure fastening provided by the Hexagonal Flange Head Cap Screw is essential for maintaining the turbocharger’s structural integrity and operational efficiency.

Conclusion

Overall, the Hexagonal Flange Head Cap Screw is a versatile fastener that contributes to the reliable operation of various engine components by providing a strong, tamper-resistant connection. Its role in engine systems, from ECM mounting to turbocharger assemblies, underscores its importance in maintaining the structural and operational integrity of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.