This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3863998 Hexagon Flange Head Cap Screw, manufactured by Cummins, is a critical component in the commercial truck industry. This screw is essential for the assembly and maintenance of various truck components, ensuring secure fastening and reliable performance under demanding conditions.

Basic Concepts

A Hexagon Flange Head Cap Screw is characterized by its hexagonal head and flange, providing a larger bearing surface and easier handling during installation and removal. This design allows for more effective distribution of clamping force, reducing the risk of damage to fastened materials. In mechanical systems, these screws secure components together, ensuring structural integrity and operational efficiency 1.

Purpose and Role in Truck Operation

The 3863998 Hexagon Flange Head Cap Screw is used to fasten critical components in commercial trucks, ensuring they remain securely in place under various operational stresses. This screw contributes to the overall reliability and safety of the truck by maintaining the integrity of its assemblies 2.

Key Features

The 3863998 Hexagon Flange Head Cap Screw features a hexagonal flange head design, facilitating easy installation and removal using standard tools. It is composed of high-strength materials, ensuring durability and resistance to wear. The threading specifications are designed to provide a secure fit, enhancing fastening security in applications with vibration and dynamic loads 3.

Benefits

Utilizing the 3863998 Hexagon Flange Head Cap Screw offers several advantages. Its design enhances fastening security, providing a stable connection between components. The screw’s resistance to vibration ensures that fastenings remain secure over time, reducing the need for frequent maintenance. Additionally, the ease of installation and removal simplifies repair and maintenance procedures, contributing to overall efficiency 4.

Installation and Usage

Proper installation of the 3863998 Hexagon Flange Head Cap Screw involves adhering to specified torque values to ensure a secure yet non-damaging fit. Recommended tools for installation include torque wrenches and hexagonal socket wrenches, which allow for precise application of force. Following manufacturer guidelines for installation ensures the screw performs its intended function effectively 5.

Troubleshooting and Maintenance

Common issues with the 3863998 Hexagon Flange Head Cap Screw may include loosening due to vibration or corrosion. Regular inspection and maintenance, such as tightening to the specified torque and applying anti-seize compounds where appropriate, can help prevent these issues. Addressing problems promptly ensures the longevity and performance of the screw and the components it secures 6.

Safety Considerations

When working with the 3863998 Hexagon Flange Head Cap Screw, it is important to follow safety precautions to prevent accidents and injuries. This includes wearing appropriate personal protective equipment, using the correct tools for installation and removal, and adhering to torque specifications to avoid over-tightening, which can lead to component damage or failure 7.

Cummins Overview

Cummins is a well-established manufacturer in the commercial truck industry, known for its high-quality engines, components, and aftermarket parts. With a history of innovation and commitment to excellence, Cummins products are designed to meet the demanding requirements of commercial trucking, ensuring reliability, performance, and durability in various applications 8.

Engine Compatibility with Hexagon Flange Head Cap Screw

The Cummins part number 3863998, a Hexagon Flange Head Cap Screw, is designed to fit seamlessly into various engine models, ensuring secure fastening and reliable performance. This part is particularly compatible with the following Cummins engine series:

4B3.9 and 6B5.9 Engines

The 3863998 Hexagon Flange Head Cap Screw is engineered to integrate with the 4B3.9 and 6B5.9 engines, providing essential fastening for critical components within these engine systems. Its robust design ensures that it can withstand the operational stresses and environmental conditions these engines encounter, maintaining the integrity of the engine assembly 9.

Application in Engine Systems

In the 4B3.9 and 6B5.9 engines, the 3863998 screw is utilized in various applications, including:

- Securing engine covers and housings

- Fastening internal components that require precise alignment and stability

- Ensuring that engine parts remain tightly secured under high-stress conditions

The screw’s flange head design allows for a secure grip, while the hexagonal shape facilitates easy and efficient tightening with standard tools. This compatibility ensures that the engine components remain firmly in place, contributing to the overall reliability and longevity of the engine 10.

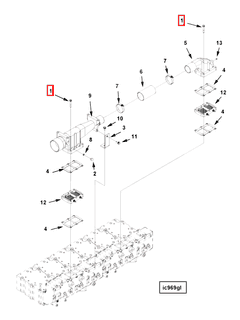

Role of Part 3863998 Hexagon Flange Head Cap Screw in Engine Systems

The 3863998 Hexagon Flange Head Cap Screw is instrumental in securing various components within engine systems, ensuring stability and reliable operation.

In the air intake connection, this screw plays a significant role in fastening the intake manifold to the engine block. This secure attachment is essential for maintaining an airtight seal, which is vital for optimal airflow into the combustion chamber 11.

For the engine control module (ECM) mounting, the Hexagon Flange Head Cap Screw is used to firmly attach the ECM to its designated location. This ensures that the ECM remains stable and unaffected by engine vibrations, allowing it to accurately monitor and control engine functions 12.

In the fuel injection pump assembly, this screw is employed to secure the pump housing and various internal components. Proper fastening is necessary to maintain the pump’s structural integrity and ensure precise fuel delivery 13.

When it comes to the fuel pump and its mounting, the Hexagon Flange Head Cap Screw is utilized to attach the fuel pump to the fuel tank or engine block. This secure attachment is important for maintaining the pump’s alignment and operational efficiency 14.

Similarly, in the fuel pump mounting system, this screw ensures that the fuel pump remains firmly in place, reducing the risk of fuel leaks and ensuring consistent fuel pressure 15.

Lastly, in the fuel shutoff valve, the Hexagon Flange Head Cap Screw is used to secure the valve housing and internal components. This ensures that the valve operates smoothly and reliably, allowing for safe and efficient fuel management within the engine system 16.

Conclusion

The 3863998 Hexagon Flange Head Cap Screw is a vital component in the commercial truck industry, offering secure fastening and reliable performance. Its design, compatibility with Cummins engines, and role in various engine systems highlight its importance in maintaining the structural integrity and operational efficiency of commercial trucks.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones & Bartlett Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones & Bartlett Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones & Bartlett Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones & Bartlett Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.