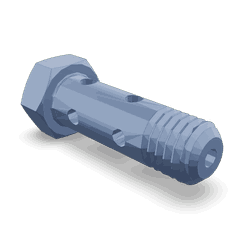

3863133

Banjo Connector Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3863133 Banjo Connector Screw, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part is integral to the vehicle’s fluid systems, facilitating the secure connection of hoses and pipes. Its role is to ensure the efficient transfer of fluids, contributing to the overall performance and reliability of the truck.

Basic Concepts of Banjo Connector Screws

A banjo connector screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with a tube or “banjo” fitting attached perpendicularly. When tightened, the banjo connector screw creates a seal, allowing fluid to flow through the system. These connectors are commonly made from materials like steel or brass, chosen for their durability and resistance to corrosion 1.

Role of the 3863133 Banjo Connector Screw in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by connecting critical fluid systems. It is often used in hydraulic and fuel systems, where it ensures the secure transfer of fluids under pressure. By maintaining a leak-free connection, this component contributes to the efficient operation of the truck’s systems.

Key Features of the 3863133 Banjo Connector Screw

The 3863133 Banjo Connector Screw is characterized by several key features that enhance its functionality. Its design includes a robust banjo fitting that provides a secure connection point for hoses. The screw is typically made from high-quality materials to ensure durability and resistance to the corrosive effects of various fluids. Additionally, the screw may feature threading that is compatible with standard fittings, facilitating easy installation.

Benefits of Using the 3863133 Banjo Connector Screw

Utilizing the 3863133 Banjo Connector Screw in commercial trucks offers several advantages. Its design contributes to improved reliability by ensuring a secure and leak-free connection. The ease of installation is another benefit, as the screw can be quickly attached or removed with standard tools. Moreover, its construction from durable materials reduces the need for frequent maintenance, offering long-term cost savings.

Installation and Usage Guidelines

Proper installation of the 3863133 Banjo Connector Screw is crucial for ensuring a secure and leak-free connection. Begin by cleaning the connection points to remove any debris or corrosion. Apply a compatible sealant to the threads of the screw to enhance the seal. Carefully thread the screw into the fitting, ensuring it is tightened to the manufacturer’s specified torque to avoid over-tightening, which could damage the fitting or cause leaks.

Troubleshooting Common Issues

Common issues with banjo connector screws include leaks and corrosion. To address leaks, first, ensure the screw is properly tightened. If leaks persist, inspect the fitting and hose for damage or wear. Corrosion can be mitigated by using screws made from corrosion-resistant materials and by applying a protective coating to the fitting. Regular inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the 3863133 Banjo Connector Screw is vital for ensuring its longevity and optimal performance. Periodic inspections should be conducted to check for signs of wear, corrosion, or leaks. Cleaning the fitting and applying a fresh sealant can help maintain a secure connection. Replacement of the screw should be considered if significant wear or damage is detected, to prevent potential system failures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive range of components, including the 3863133 Banjo Connector Screw, reflects its dedication to providing reliable and high-performance solutions for the trucking sector.

Compatibility of Part 3863133 with Cummins Engines

The Banjo Connector Screw, part number 3863133, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This component is essential for maintaining the integrity of hydraulic and fuel lines by providing a secure connection that can withstand high pressure and vibrations.

Engines Compatible with Part 3863133

-

6B5.9

- The 6B5.9 engine benefits from the reliability and durability of the 3863133 Banjo Connector Screw, ensuring that critical connections remain tight and leak-free.

-

QSB3.3 CM2250 EC

- In the QSB3.3 CM2250 EC engine, the 3863133 part is crucial for maintaining the efficiency of hydraulic systems, contributing to the overall performance and longevity of the engine.

-

QST30 CM2350 T101 and QST30 CM552

- Both the QST30 CM2350 T101 and QST30 CM552 engines utilize the 3863133 Banjo Connector Screw to secure various hydraulic and fuel lines. This part ensures that these engines operate smoothly by preventing leaks and maintaining pressure integrity.

By integrating the 3863133 Banjo Connector Screw into these engines, Cummins ensures that the connections are robust and reliable, contributing to the overall efficiency and durability of the engines.

Role of Part 3863133 Banjo Connector Screw in Various Engine Systems

The 3863133 Banjo Connector Screw is an integral component in several engine systems, facilitating the secure connection of various fluid lines and ensuring the efficient operation of these systems.

In the compressor system, the Banjo Connector Screw is used to join the high-pressure and low-pressure sides, allowing for the smooth transfer of refrigerant. This ensures the compressor can effectively regulate temperature and pressure within the system.

Within the air coupling system, this screw plays a role in connecting the air lines that supply pressurized air to various components. It ensures a leak-free connection, which is essential for maintaining the integrity of the air supply and the performance of the coupled components.

In the fuel pump system, the Banjo Connector Screw is employed to connect the fuel lines that deliver fuel from the tank to the engine. This secure connection is vital for maintaining consistent fuel pressure and flow, which directly impacts engine performance and efficiency.

For the drive system, particularly in the context of the front gear train accessory, the Banjo Connector Screw is used in hydraulic lines that power various accessories. This ensures that the hydraulic fluid is delivered under the correct pressure, allowing these accessories to function smoothly and reliably.

In plumbing applications related to engine systems, the Banjo Connector Screw is utilized to join various fluid lines, whether they carry coolant, oil, or other fluids. This ensures that these fluids are delivered to their respective components without leaks, maintaining the overall efficiency and reliability of the engine.

In the fuel system, the screw is integral in connecting fuel injectors and other components, ensuring that fuel is delivered precisely when and where it is needed. This is fundamental for the engine’s combustion process and overall performance.

Lastly, in the auxiliary cooling system, the Banjo Connector Screw is used to connect coolant lines that help regulate the temperature of various engine components. This is essential for preventing overheating and ensuring the longevity and reliability of the engine.

Conclusion

The 3863133 Banjo Connector Screw is a critical component in the operation of commercial trucks, particularly those equipped with Cummins engines. Its role in ensuring secure and leak-free connections in various fluid systems contributes to the overall performance, reliability, and efficiency of the vehicle. Proper installation, regular maintenance, and timely replacement of this part are essential practices to ensure the longevity and optimal performance of the truck’s systems.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.