This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

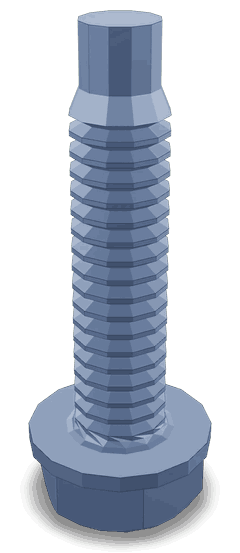

The 3820537 Self Tapping Metal Screw is a specialized fastener produced by Cummins, a well-established manufacturer in the commercial truck industry. This screw is designed for use in various applications within commercial trucks, providing reliable fastening solutions that contribute to the overall performance and durability of truck components.

Basic Concepts of Self Tapping Metal Screws

Self tapping metal screws are fasteners that can create their own mating threads in a material as they are driven in. This eliminates the need for pre-tapping, making them highly efficient for various applications 1. In the automotive industry, these screws are commonly used for assembling body panels, attaching brackets, and securing various components due to their ease of use and strong holding power.

Purpose of the 3820537 Self Tapping Metal Screw

This Cummins part plays a role in the operation and maintenance of commercial trucks by providing secure fastening in a variety of applications. It is used in attaching body panels, securing brackets, and fastening other components where a strong, durable connection is required. Its design ensures that it can withstand the vibrations and stresses encountered in truck environments, contributing to the structural integrity and longevity of the truck.

Key Features

The 3820537 Self Tapping Metal Screw features a robust material composition, typically made from high-strength steel, which enhances its durability and resistance to corrosion. Its thread design is optimized for efficient tapping and secure fastening, ensuring a strong hold in various materials. Additionally, the screw may have unique attributes such as a coated finish to further improve corrosion resistance and longevity.

Benefits

Using this part offers several benefits. It improves fastening efficiency by eliminating the need for pre-tapping, which saves time during installation. The screw provides enhanced structural integrity by creating a strong, secure connection that can withstand the demanding conditions of commercial truck environments. Its long-term reliability ensures that truck components remain securely fastened, reducing the need for frequent maintenance and replacements.

Installation Process

Proper installation of the 3820537 Self Tapping Metal Screw involves several steps to ensure optimal performance and longevity. Begin by selecting the appropriate drill bit size to create a pilot hole, which helps guide the screw and reduce the risk of stripping. Use a power drill to create the pilot hole at the desired location. Then, drive the screw into the pilot hole using a screwdriver or power drill, ensuring it is fully seated and secure. Check the tightness of the screw to confirm a strong hold.

Troubleshooting and Maintenance

Common issues with self tapping metal screws include stripped threads and loose connections. To troubleshoot these problems, inspect the screw and surrounding material for signs of damage or wear. If the screw is loose, it may need to be replaced or tightened. Regular maintenance involves checking the screws for signs of corrosion or damage and ensuring they remain securely fastened. Applying a corrosion-resistant coating can help prolong the life of the screw and ensure continued reliable performance.

Cummins: Manufacturer Overview

Cummins Inc. is a globally recognized leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for producing high-quality, reliable components for the commercial truck industry. Their extensive product range and commitment to innovation make them a trusted source for truck components, ensuring that their products meet the rigorous demands of commercial applications 2.

Cummins Self Tapping Metal Screw Part 3820537 Compatibility

The Cummins Self Tapping Metal Screw part number 3820537 is designed to fit seamlessly with several of Cummins’ engine models. This screw is engineered for durability and precision, ensuring it meets the rigorous demands of engine assembly and maintenance.

ISB6.7 G CM2180 B118, ISG12 G CMOH6.0 G111, and ISL G CM2180 Engines

This specific screw is compatible with the ISB6.7 G CM2180 B118, ISG12 G CMOH6.0 G111, and ISL G CM2180 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The self-tapping feature of part 3820537 allows it to create its own threads in metal, making installation straightforward and efficient. This is particularly beneficial in engine environments where precision and ease of assembly are critical.

L10 MECHANICAL Engine

The Cummins Self Tapping Metal Screw part number 3820537 also fits the L10 MECHANICAL engine. This engine, while differing in design from the others, still benefits from the screw’s ability to provide a secure and reliable fastening solution. The self-tapping capability ensures that the screw can be used in various metal components within the engine, enhancing the overall integrity of the assembly.

Grouping by Application

When considering the application of part 3820537 across these engines, it is important to note that the screw’s design is optimized for heavy-duty use. Whether it is for securing engine components, mounting brackets, or other critical parts, this screw provides a dependable fastening solution. The compatibility across multiple engine models underscores its versatility and the importance of using genuine Cummins parts for maintenance and repairs.

Role of Part 3820537 Self Tapping Metal Screw in Engine Systems

In the intricate assembly of engine systems, the part 3820537 Self Tapping Metal Screw serves as a vital fastening element. This screw is instrumental in securing various components, ensuring structural integrity and operational efficiency.

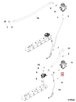

Breather Systems

Within breather systems, the 3820537 screw is utilized to attach the breather housing to the engine block or crankcase. This secure attachment is essential for maintaining the breather’s function, which is to regulate pressure and allow for the escape of contaminants from the crankcase. Proper fastening prevents leaks and ensures that the breather system operates effectively, contributing to the engine’s longevity and performance.

Crankcase Assembly

In the crankcase assembly, the 3820537 screw plays a significant role in attaching panels and covers. These panels are critical for protecting the internal components of the crankcase from external contaminants and for maintaining the structural integrity of the engine. The screw’s self-tapping feature allows for efficient installation, reducing assembly time and ensuring a tight, secure fit that withstands the vibrations and stresses inherent in engine operation.

Noise Reduction Components

For noise reduction components, such as acoustic panels or vibration dampeners, the 3820537 screw is employed to fasten these elements to the engine frame or other structural parts. Effective noise management is essential for both the comfort of the vehicle’s occupants and for meeting regulatory standards. The secure attachment provided by the screw ensures that these components remain in place, effectively reducing engine noise and vibration.

Panel Attachments

The 3820537 screw is also commonly used for attaching various panels within the engine compartment. These panels may serve multiple purposes, including shielding sensitive components from debris, directing airflow for cooling, or simply providing a streamlined aesthetic. The screw’s design ensures that these panels are held firmly in place, preventing them from becoming dislodged during operation and maintaining the engine’s overall efficiency and safety.

Conclusion

The 3820537 Self Tapping Metal Screw is a critical component in the assembly and maintenance of commercial truck engines. Its robust design, ease of installation, and compatibility with various Cummins engine models make it an indispensable part for ensuring the structural integrity and operational efficiency of truck components. Regular maintenance and proper installation are essential to maximize the benefits of this screw, contributing to the longevity and performance of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.