3820336

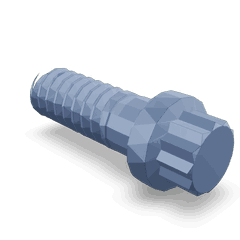

Twelve Point Cap Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Twelve Point Cap Screw, Part #3820336 by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a renowned manufacturer in the automotive industry, produces this component to meet the demanding requirements of truck operations. This screw plays a role in ensuring the reliability and efficiency of heavy-duty trucks.

Basic Concepts

A Twelve Point Cap Screw is a type of fastener characterized by its twelve-sided head, which provides a larger contact area compared to traditional hex-head screws. This design allows for more torque to be applied without rounding off the corners, making it less prone to stripping 1. Unlike other fasteners, such as bolts or standard cap screws, the twelve-point design offers enhanced grip and stability during installation and removal.

Purpose and Role in Truck Operation

The Twelve Point Cap Screw is integral to the operation and maintenance of heavy-duty trucks. It is commonly used in applications where high torque and secure fastening are required, such as in engine components, transmission systems, and chassis assemblies. Its role is to provide a strong, reliable connection that can withstand the rigors of heavy-duty use, ensuring that critical components remain securely fastened under various operating conditions.

Key Features

The Twelve Point Cap Screw boasts several key features that enhance its performance. Its twelve-sided head design allows for greater torque application and reduced risk of rounding. The screw is typically made from high-strength materials, such as alloy steel, to ensure durability and resistance to wear. Additionally, it may feature a coated surface to protect against corrosion, extending its lifespan in harsh environments 2.

Benefits

Using a Twelve Point Cap Screw in truck applications offers several advantages. Its design provides superior resistance to loosening, which is crucial in dynamic environments where vibrations are common. The increased torque capacity allows for tighter fastening, enhancing the security of critical components. Furthermore, the ease of installation and removal, thanks to its unique head design, saves time during maintenance procedures.

Installation Process

Proper installation of the Twelve Point Cap Screw is vital for optimal performance. Begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to apply the specified torque, following the manufacturer’s recommendations to avoid over-tightening or under-tightening. It is important to use the correct socket or wrench that matches the twelve-point head to prevent damage. After installation, periodically check the fastener to ensure it remains secure 3.

Troubleshooting and Maintenance

Common issues with Twelve Point Cap Screws include loosening due to vibrations and corrosion. To identify problems, regularly inspect the fasteners for signs of wear, corrosion, or movement. Maintenance tips include applying a thread locker to prevent loosening, using corrosion-resistant coatings, and ensuring proper torque during installation. Replacing screws that show signs of wear or damage will help maintain the integrity of the truck’s components.

Safety Considerations

When working with Twelve Point Cap Screws, it is important to follow safety practices to ensure personal protection and component integrity. Use the appropriate personal protective equipment, such as gloves and safety glasses. Adhere to torque specifications provided by the manufacturer to prevent over-tightening, which can lead to component damage, or under-tightening, which can result in loosening. Handle the screws carefully to avoid injury from sharp edges.

Cummins Overview

Cummins is a well-established name in the automotive industry, known for its high-quality components and innovative solutions. With a history of producing reliable and durable parts, Cummins has built a reputation for excellence. The company’s commitment to quality is evident in its rigorous testing and manufacturing processes, ensuring that each component, including the Twelve Point Cap Screw, meets the highest standards for performance and reliability in heavy-duty applications.

Twelve Point Cap Screw 3820336 in Cummins Engines

The Twelve Point Cap Screw 3820336 is a critical component in various Cummins engine models, ensuring secure fastening and stability across different engine configurations. This screw is integral to the assembly and maintenance of numerous engine parts, contributing to the overall reliability and performance of the engines.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, utilize the Twelve Point Cap Screw 3820336 in various applications. This screw is essential for securing components within the engine’s framework, ensuring that parts remain firmly in place under operational stresses.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

In the L10 series engines, such as the L10 CELECT, L10 GAS, and L10 MECHANICAL, the Twelve Point Cap Screw 3820336 plays a pivotal role in maintaining the structural integrity of the engine. This screw is used in areas where high precision and durability are required, ensuring that the engine components are fastened securely and can withstand the demands of their operational environment.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, also rely on the Twelve Point Cap Screw 3820336 for critical fastening applications. This screw is used in various parts of the engine to ensure that components are held together firmly, contributing to the engine’s overall performance and longevity.

QSM11 Series Engines

- QSM11 CM570

- QSM11 CM876

In the QSM11 series engines, such as the QSM11 CM570 and QSM11 CM876, the Twelve Point Cap Screw 3820336 is employed in several key areas. This screw is essential for securing components that are subject to significant mechanical stresses, ensuring that the engine operates smoothly and efficiently.

Role of Part 3820336 Twelve Point Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 3820336 Twelve Point Cap Screw is instrumental in ensuring the secure and reliable attachment of various components. This screw is particularly significant in the following applications:

Mounting

The Twelve Point Cap Screw is commonly used in mounting applications where it secures engine components to the chassis or other structural elements. Its design allows for a firm grip, minimizing the risk of loosening due to vibrations or thermal expansion, which are common in engine environments.

Starting Motor

In the starting motor assembly, the Twelve Point Cap Screw plays a key role in attaching the motor to the engine block. This secure attachment is essential for the efficient transfer of torque from the starter motor to the flywheel, ensuring a smooth and reliable engine start.

Starter Mounting

For starter mounting, the screw is used to fasten the starter motor to its designated position on the engine. This secure fit is vital for the proper alignment and operation of the starter, contributing to the overall reliability of the engine’s starting system.

Support

In support applications, the Twelve Point Cap Screw is employed to reinforce various engine components, such as brackets and mounts. This reinforcement is important for maintaining the structural integrity of the engine, especially under the stress of high RPMs and dynamic loads.

Rear Engine

At the rear of the engine, the screw is often used to secure components such as exhaust manifolds, transmission mounts, and other rear-mounted accessories. Its robust design ensures that these components remain firmly in place, even under the harsh conditions of engine operation.

Conclusion

Overall, the part 3820336 Twelve Point Cap Screw is a versatile and reliable fastener that contributes to the secure and efficient operation of various engine systems. Its unique design and high-strength materials make it an essential component in the assembly and maintenance of heavy-duty trucks and engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.