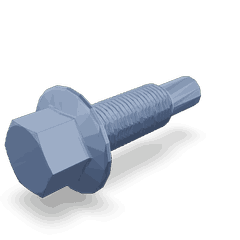

3698430

Hexagon Flange Head Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by Part #3698430, is a component manufactured by Cummins, a well-regarded name in the automotive and heavy-duty truck industry. This screw is significant in commercial trucks due to its robust design and reliable performance, contributing to the overall efficiency and durability of truck components.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute load and prevent the screw from sinking into the material. In a truck’s mechanical system, this screw plays a role in securing various components, ensuring they remain firmly in place under operational stress.

Purpose and Role in Truck Operation

This Cummins part is utilized in several applications within a truck’s mechanical system. It is commonly employed in fastening engine components, transmission parts, and chassis assemblies. Its role is to provide a secure connection that can withstand the vibrations and loads experienced during truck operation. The screw’s design ensures that critical components remain attached, contributing to the truck’s overall performance and safety.

Key Features

The 3698430 boasts several key features that enhance its functionality. Its hexagonal head design allows for straightforward installation and removal using common tools. The flange beneath the head provides added stability by distributing the load over a larger surface area, which helps prevent the screw from pulling through the material. Additionally, the screw is typically made from high-strength materials, ensuring durability in heavy-duty applications.

Benefits

The benefits of using the 3698430 include enhanced stability due to its flange design, which reduces the likelihood of the screw pulling through the material. Its resistance to loosening under vibration is another significant advantage, ensuring that fastened components remain secure over time. Furthermore, the screw’s durable material composition makes it suitable for heavy-duty applications, contributing to the longevity of truck components.

Installation and Usage

Proper installation of the 3698430 is vital for ensuring its effectiveness. It should be installed using the appropriate torque specifications to achieve the desired clamping force without over-tightening, which could damage the screw or the material it is fastening. Best practices include using a torque wrench to apply the correct amount of torque and ensuring that the screw is aligned properly with the fastened components.

Troubleshooting and Maintenance

Common issues with the 3698430 may include loosening over time due to vibration or corrosion. Regular inspections can help identify such issues early. Maintenance tips include ensuring that the screw and surrounding components are free from corrosion and that the screw is tightened to the manufacturer’s specified torque settings during periodic checks. Replacing screws that show signs of wear or damage is also recommended to maintain optimal performance.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable components, Cummins has established a strong reputation for delivering products that meet the demanding requirements of commercial trucking. Their focus on quality ensures that components like the 3698430 are designed to perform reliably in challenging environments.

Application in Cummins Engines

ISG11 CM2880 G108 and ISG12 CM2880 G107

These engines utilize the Hexagon Flange Head Cap Screw in several key areas. The screw is often employed in securing engine covers, ensuring that they are tightly fastened to prevent any leaks or failures. Additionally, it is used in the assembly of various engine sub-assemblies, providing the necessary strength and stability.

ISG12 G CMOH6.0 G111

In this engine model, the part 3698430 is used in the fastening of critical engine components. Its flange head design allows for a secure fit, which is essential for maintaining the integrity of the engine’s structure. The screw’s robust construction ensures that it can withstand the high torque and stress conditions typical in engine operations.

QSG12 CM2880 G112 and QSG12/X12 CM2350 G110

These engines also benefit from the use of the Hexagon Flange Head Cap Screw. It is used in the assembly of the engine’s outer casing and in securing various internal components. The screw’s design allows for easy installation and removal, which is crucial during maintenance and repair operations.

X11 CM2670 X126B and X12 CM2670 X121B

In these models, the part 3698430 is employed in the fastening of engine mounts and brackets. Its flange head provides a broad surface area for the application of torque, ensuring that the mounts remain securely fastened. This is particularly important in maintaining the alignment and stability of the engine within the vehicle.

X12N CMMDG1 X143B and X13 CM2670 X122B

These engines use the Hexagon Flange Head Cap Screw in the assembly of their internal components. The screw’s design allows for precise and secure fastening, which is essential for the proper functioning of the engine. Its use in these engines ensures that all components are held firmly in place, reducing the risk of mechanical failure.

Role of Part 3698430 in Engine Systems

In the intricate assembly of engine systems, the part 3698430 serves a significant function in securing various components, ensuring the structural integrity and operational efficiency of the engine.

Securing the Oil Pan

One of the primary applications of the Hexagon Flange Head Cap Screw is in the attachment of the oil pan. The oil pan is a vital component that houses the engine’s lubricant, essential for reducing friction and wear between moving parts. The screw’s flange head design provides a larger surface area for distribution of clamping force, which is beneficial in maintaining a secure and leak-proof seal between the oil pan and the engine block. This is particularly important given the oil pan’s role in containing engine oil under pressure and during operation.

Pan Attachments and Structural Integrity

Beyond the oil pan, the Hexagon Flange Head Cap Screw is also employed in attaching various pans and covers within the engine system. These may include transmission pans, valve covers, and other ancillary components that require a robust fastening solution. The flange head not only enhances the screw’s torque capabilities but also prevents the screw from digging into the material it is securing, thereby preserving the integrity of the pan or cover.

Ensuring Stability in Oil Systems

In oil systems, where components are subject to vibrations and dynamic loads, the stability provided by the Hexagon Flange Head Cap Screw is invaluable. Whether fastening an oil filter housing or securing an oil cooler, the screw’s design ensures that these components remain firmly in place, contributing to the overall reliability of the oil circulation system. This stability is essential for maintaining consistent oil pressure and flow, which are critical for engine performance and longevity.

Conclusion

In summary, the part 3698430 plays a pivotal role in the assembly and maintenance of engine systems by providing secure and stable fastening for critical components such as the oil pan and various pans within the engine. Its design enhances both the functional and structural aspects of engine construction, contributing to the efficient and reliable operation of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.