3695535

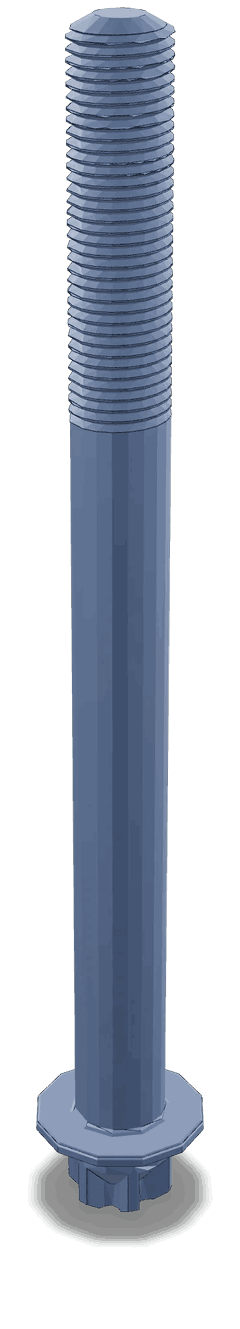

Fracture Resistant Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fracture Resistant Screw 3695535, manufactured by Cummins, is a critical component designed for use in commercial trucks. This screw ensures the reliable operation of trucks by securing critical components within the vehicle’s mechanical system, maintaining the integrity and performance of truck assemblies over time.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are specialized fasteners engineered to withstand significant mechanical stress without breaking. They securely join components together, distributing loads evenly and resisting deformation under pressure. Typically made from high-strength materials such as alloy steels or stainless steels, these screws offer superior tensile strength, durability, and resistance to corrosion. These material properties contribute to the screws’ ability to maintain structural integrity in demanding environments 1.

Role of the 3695535 Fracture Resistant Screw in Truck Operation

The 3695535 Fracture Resistant Screw secures components subject to high stress and vibration within the truck’s mechanical system. Its design and material composition contribute to the overall functionality and durability of the truck. By ensuring that critical parts remain firmly attached, this screw helps maintain the truck’s performance and reliability over its operational life 2.

Key Features

The 3695535 Fracture Resistant Screw features a threaded shaft and a head for driving. It is composed of materials that provide high tensile strength and resistance to fracture. Unique attributes of this screw include precision machining for accurate fitment, surface treatments for enhanced corrosion resistance, and a design that allows for efficient load distribution. These features collectively enhance its performance and longevity in commercial truck applications.

Benefits

Using the 3695535 Fracture Resistant Screw offers several benefits. Its improved durability ensures it can withstand the mechanical stresses encountered in truck operations. The screw’s resistance to fracture reduces the likelihood of component failure, contributing to safer and more reliable truck performance. Additionally, its longevity in harsh operating conditions means that it requires less frequent replacement, offering cost savings and reduced maintenance efforts over time.

Troubleshooting and Maintenance

Common issues with the 3695535 screw may include corrosion, wear, or loosening due to vibration. Troubleshooting involves inspecting the screw for signs of damage or corrosion, ensuring that it is properly torqued, and verifying that the components it secures are functioning correctly. Maintenance practices include regular inspection, cleaning to remove corrosive agents, and re-torquing as necessary to maintain secure fastening. These practices help ensure optimal performance and longevity of the screw.

About Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. The company is known for its commitment to quality and innovation in producing automotive components. Cummins’ history of delivering reliable and high-performance parts underscores its position as a trusted provider in the industry 2.

Compatibility with Cummins Engines

The Fracture Resistant Screw part number 3695535 is designed to be compatible with various Cummins engine models. This screw is engineered to withstand the rigors of engine operation, ensuring reliability and durability in demanding conditions.

ISG11 CM2880 G108 and ISG12 CM2880 G107

The Fracture Resistant Screw 3695535 is suitable for use in the ISG11 CM2880 G108 and ISG12 CM2880 G107 engines. These engines are part of the Cummins ISG series, known for their robust design and performance in industrial applications. The screw’s compatibility with these models ensures that it can effectively secure components within these engines, maintaining structural integrity and operational efficiency.

ISG12 G CMOH6.0 G111

This screw is also compatible with the ISG12 G CMOH6.0 G111 engine. This engine model is another variant within the Cummins ISG series, featuring the CMOH6.0 technology. The Fracture Resistant Screw 3695535 is engineered to meet the specific requirements of this engine, providing a reliable fastening solution that can endure the stresses encountered during operation.

QSG12 CM2880 G112

The QSG12 CM2880 G112 engine is another model that benefits from the use of the Fracture Resistant Screw 3695535. This engine is part of the Cummins QSG series, designed for high-performance applications. The screw’s compatibility with this model ensures that it can securely fasten components, contributing to the engine’s overall reliability and longevity.

QSG12/X12 CM2350 G110

The Fracture Resistant Screw 3695535 is also suitable for the QSG12/X12 CM2350 G110 engine. This engine model combines the QSG and X12 series, offering a versatile solution for various industrial applications. The screw’s design ensures it can withstand the operational stresses of this engine, providing a dependable fastening solution.

X12 CM2350 X119B

The X12 CM2350 X119B engine is another model that can utilize the Fracture Resistant Screw 3695535. This engine is part of the Cummins X12 series, known for its efficiency and reliability. The screw’s compatibility with this model ensures it can effectively secure components, contributing to the engine’s performance and durability.

X12 CM2670 X121B and X13 CM2670 X122B

The Fracture Resistant Screw 3695535 is also compatible with the X12 CM2670 X121B and X13 CM2670 X122B engines. These engines are part of the Cummins X12 and X13 series, designed for heavy-duty applications. The screw’s design ensures it can endure the operational stresses of these engines, providing a reliable fastening solution that supports the engine’s performance and longevity.

Role of Part 3695535 Fracture Resistant Screw in Engine Systems

Part 3695535 Fracture Resistant Screw is integral to the secure assembly and reliable operation of various engine components. Its application ensures that the connections between parts remain intact under high stress and dynamic conditions.

Camshaft and Rocker Lever Assembly

In the camshaft and rocker lever assembly, Part 3695535 is used to fasten the rocker levers to the camshaft. This secure attachment is vital for the precise transfer of motion from the camshaft to the valves, ensuring optimal valve timing and engine performance.

Connecting Rod and Piston

For the connecting rod and piston assembly, this fracture-resistant screw plays a role in securing the connecting rod to the crankshaft. It withstands the immense forces generated during the power stroke, maintaining the integrity of the connection and contributing to smooth engine operation.

Cylinder Head and Head Components

When attaching the cylinder head to the engine block, Part 3695535 is employed to ensure a tight and consistent seal. This is essential for maintaining compression within the combustion chamber and preventing leaks that could degrade engine efficiency.

Injector Mounting

In fuel injection systems, this screw is used to mount injectors securely within the cylinder head. Proper attachment ensures that injectors remain in the correct position, allowing for precise fuel delivery and combustion.

General Component Integration

Across various engine parts, Part 3695535 Fracture Resistant Screw provides a reliable means of fastening components together. Its resistance to fracture under stress makes it suitable for applications where durability and consistent performance are required.

Conclusion

The Fracture Resistant Screw 3695535 by Cummins is a vital component in ensuring the reliable and durable operation of commercial trucks and various Cummins engine models. Its high-strength material composition, precise design, and resistance to fracture make it an essential part in securing critical engine components. By understanding its role, features, and benefits, users can ensure optimal performance and longevity of their vehicles and engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.