This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

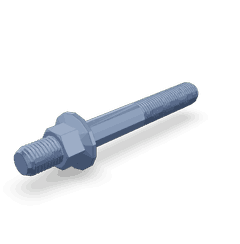

The Studded Flange Cap Screw, Part #3694927, manufactured by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this component to meet the rigorous demands of truck mechanics and operators. This screw is integral to ensuring the secure attachment of various components within a truck’s mechanical system.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud provides a continuous thread that can be used with a nut, while the flange offers additional surface area for torque application, enhancing the screw’s holding power. In a truck’s mechanical system, this screw plays a role in securely fastening components that are subject to significant stress and vibration 1.

Purpose and Role in Truck Operation

The 3694927 Studded Flange Cap Screw is utilized in various truck systems where secure and durable fastening is required. It is commonly applied in engine components, transmission systems, and chassis assemblies. By providing a robust connection, this screw helps maintain the integrity of these systems under the demanding conditions typical of heavy-duty truck operation 2.

Key Features

The 3694927 Studded Flange Cap Screw is crafted from high-strength materials, ensuring durability and resistance to wear. Its design includes a flanged head that distributes torque more effectively, reducing the risk of stripping or loosening. Additionally, the screw features a precision-machined thread that ensures a tight and secure fit, enhancing its performance in high-stress applications 3.

Benefits

Using the 3694927 Studded Flange Cap Screw offers several advantages. Its high-strength material composition contributes to durability, while the flanged design enhances reliability by providing a secure attachment point. This screw also facilitates efficient maintenance and operation, as its design allows for easy installation and removal, reducing downtime during truck servicing.

Installation Process

Installing the 3694927 Studded Flange Cap Screw requires the use of appropriate tools, such as a torque wrench, to ensure the correct fitting. The process involves threading the stud into the designated hole, applying the specified torque to secure it in place, and then attaching a nut if necessary. Following the manufacturer’s guidelines for torque settings is crucial to achieve the optimal fastening strength.

Troubleshooting and Maintenance

Common issues with Studded Flange Cap Screws include loosening due to vibration or corrosion. Regular inspection and maintenance, such as tightening to the recommended torque settings and applying anti-seize compound, can help prevent these problems. Additionally, replacing screws that show signs of wear or damage ensures the continued reliability of the truck’s mechanical systems.

Safety Considerations

When working with the 3694927 Studded Flange Cap Screw, it is important to observe safety guidelines to protect mechanics and operators. This includes using the correct tools and following torque specifications to avoid over-tightening, which can lead to damage. Additionally, wearing appropriate personal protective equipment (PPE) is recommended to safeguard against injuries during installation and maintenance procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Studded Flange Cap Screw (Part 3694927) Compatibility with Cummins Engines

The Studded Flange Cap Screw, identified as part number 3694927, is a critical component in the assembly and maintenance of various Cummins engines. This part is designed to securely fasten flanges and other components, ensuring the integrity and functionality of the engine system. Below is a detailed overview of the engines with which this part is compatible.

CM2670 Series Engines

The CM2670 series engines include:

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- L9 CM2670 L128B

- X11 CM2670 X126B

- X12 CM2670 X121B

- X13 CM2670 X122B

These engines are part of the CM2670 family, which are known for their robust design and reliability. The Studded Flange Cap Screw is integral to these engines, providing the necessary fastening for various flanges and covers.

CM2620 Series Engines

The CM2620 series engines include:

- D4.0 CM2620 D103B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

These engines are also part of the CM2620 family, which are designed for high performance and durability. The Studded Flange Cap Screw is used extensively in these engines to ensure that all flanged components are securely fastened.

CM2150 Series Engines

The CM2150 series engine includes:

- ISB/ISD4.5 CM2150 B119

This engine is known for its power and efficiency. The Studded Flange Cap Screw is essential for maintaining the structural integrity of the engine by securing various flanges.

CM850 Series Engines

The CM850 series engine includes:

- ISBE4 CM850

This engine is designed for heavy-duty applications. The Studded Flange Cap Screw plays a crucial role in ensuring that all flanged components are properly fastened.

CM2880 Series Engines

The CM2880 series engines include:

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- QSG12 CM2880 G112

These engines are part of the CM2880 family, which are engineered for high performance. The Studded Flange Cap Screw is used to secure flanges and covers, ensuring the engine’s components are tightly fastened.

CMOH6.0 Series Engines

The CMOH6.0 series engine includes:

- ISG12 G CMOH6.0 G111

This engine is designed for specific applications requiring high performance. The Studded Flange Cap Screw is used to ensure that all flanged components are securely fastened.

CM2350 Series Engines

The CM2350 series engine includes:

- QSG12/X12 CM2350 G110

This engine is part of the CM2350 family, which is known for its reliability. The Studded Flange Cap Screw is used to secure flanges and covers, ensuring the engine’s components are tightly fastened.

X143B Series Engines

The X143B series engine includes:

- X12N CMMDG1 X143B

This engine is designed for specific applications. The Studded Flange Cap Screw is used to secure flanges and covers, ensuring the engine’s components are tightly fastened.

The Studded Flange Cap Screw is a versatile and essential component in the assembly and maintenance of Cummins engines. Its use across various engine series highlights its importance in ensuring the structural integrity and functionality of these engines.

Role of Part 3694927 Studded Flange Cap Screw in Engine Systems

The 3694927 studded flange cap screw is instrumental in securing and maintaining the integrity of various engine components. Its application spans across multiple systems, ensuring that parts remain firmly in place under operational stress.

Drive System

In the drive system, the 3694927 screw is often used to fasten components such as drive plates and coupling mechanisms. This ensures that the drive components remain aligned and securely attached, which is essential for the smooth transfer of power from the engine to the transmission.

Fan Assembly

Within the fan assembly, the 3694927 screw plays a role in attaching the fan blades to the fan hub. This secure attachment is vital for maintaining the fan’s efficiency in cooling the engine, especially under high-load conditions where thermal management is paramount.

Harness and Wiring

For the electronic control module (ECM) wiring and harnesses, the 3694927 screw is employed to mount wiring looms and secure sensor connections. This prevents wire fatigue and ensures that electrical connections remain intact, which is important for the reliable operation of the engine’s electronic systems.

Oil Pan

In the context of the oil pan, the 3694927 screw is used to attach the pan to the engine block. This secure fitting is necessary to prevent oil leaks and to maintain the structural integrity of the oil pan, which houses the engine’s lubricant.

Fuel System

Within the fuel system, the 3694927 screw is utilized to fasten fuel lines and components such as fuel filters and injectors. This ensures that the fuel delivery system remains sealed and operates efficiently, which is essential for consistent engine performance.

Plumbing

For engine plumbing, the 3694927 screw is often used in coolant systems to secure hoses and fittings. This helps maintain the integrity of the cooling system, ensuring that coolant flows smoothly and efficiently to regulate engine temperature.

Each of these applications demonstrates the versatility and reliability of the 3694927 studded flange cap screw in contributing to the overall functionality and durability of engine systems.

Conclusion

The 3694927 Studded Flange Cap Screw is a critical component in the maintenance and operation of heavy-duty trucks and Cummins engines. Its robust design, high-strength materials, and versatile applications make it an essential part for ensuring the secure attachment of various components within a truck’s mechanical system. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.