3692202

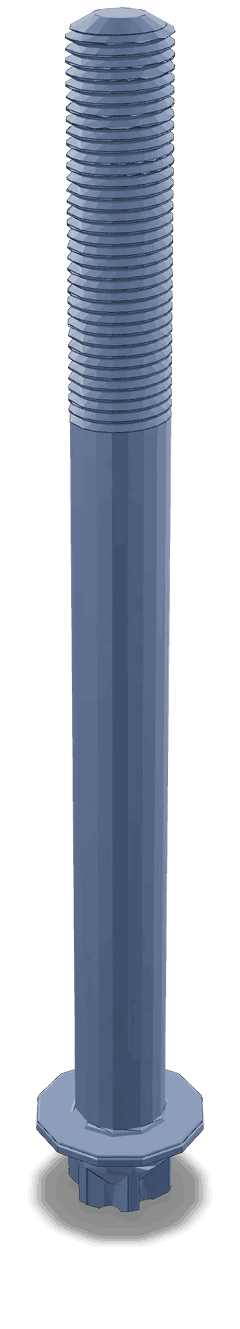

Fracture Resistant Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fracture Resistant Screw 3692202 is a specialized component designed by Cummins for use in heavy-duty truck applications. This screw is engineered to withstand significant mechanical stress and harsh operating conditions, ensuring reliable performance and longevity in demanding environments. Its role is vital in maintaining the integrity and functionality of various truck components.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are designed to offer enhanced durability and resistance to mechanical stress compared to standard screws. These screws are typically made from materials that provide superior strength and toughness, allowing them to endure high loads and repeated stress cycles without failing. In mechanical applications, fracture resistant screws play a role in securing components that are subject to significant forces, vibrations, and environmental factors 1.

Purpose and Role in Truck Operation

The 3692202 Fracture Resistant Screw is specifically designed to play a role in the operation and maintenance of commercial trucks. It is commonly used in applications where components are exposed to high stress and dynamic loads, such as in the engine, transmission, and chassis systems. The screw ensures that critical parts remain securely fastened, which is necessary for the safe and efficient operation of the truck. Its use helps prevent component failure and ensures that the truck can withstand the rigors of heavy-duty use 2.

Key Features

The 3692202 Fracture Resistant Screw boasts several key features that enhance its performance and durability. It is constructed from a high-strength alloy, which provides excellent resistance to fracture and corrosion. The screw’s design includes a threaded body that ensures a secure fit and optimal load distribution. Additionally, it may feature a special coating or treatment that further enhances its resistance to wear and environmental factors.

Benefits

Using the 3692202 Fracture Resistant Screw offers several benefits. Its high strength and durability contribute to improved reliability and reduced maintenance requirements. The screw’s resistance to mechanical stress ensures that it can withstand the demanding conditions of heavy-duty truck operations. Furthermore, its longevity in harsh environments helps to minimize downtime and repair costs, making it a cost-effective solution for truck maintenance 3.

Installation Considerations

Proper installation of the 3692202 Fracture Resistant Screw is important to ensure optimal performance and longevity. It is recommended to follow manufacturer guidelines for torque specifications to avoid over-tightening or under-tightening, which can lead to screw failure or loosening. Using the correct tools and techniques during installation helps to achieve the desired clamping force and secure fit. Additionally, ensuring that mating surfaces are clean and free of contaminants contributes to a reliable connection.

Troubleshooting and Maintenance

Common issues with fracture resistant screws may include loosening due to vibration, corrosion, or wear. Regular inspection and maintenance can help identify and address these issues before they lead to component failure. If a screw shows signs of damage or wear, it should be replaced promptly to maintain the integrity of the assembly. Applying a suitable lubricant or anti-seize compound during reinstallation can help prevent corrosion and facilitate future removal.

Comparative Analysis

When compared to standard screws, the 3692202 Fracture Resistant Screw offers superior strength and durability, making it a preferred choice for heavy-duty applications. While standard screws may be sufficient for less demanding tasks, fracture resistant screws provide the necessary resilience in high-stress environments. Other fracture resistant options in the market may vary in material composition and design, but the 3692202 screw stands out for its combination of high strength, corrosion resistance, and reliable performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Compatibility with Cummins Engines

The Fracture Resistant Screw part number 3692202, manufactured by Cummins, is designed to fit a variety of their engine models. This part is crucial for maintaining the structural integrity of the engine by preventing fractures that could occur under high stress conditions.

ISG11 CM2880 G108 and ISG12 CM2880 G107

These engines, both part of the ISG series, are equipped with the Fracture Resistant Screw 3692202. This screw is integral in securing components that are subject to significant mechanical stress, ensuring the longevity and reliability of the engine.

ISG12 G CMOH6.0 G111

In the ISG12 G CMOH6.0 G111 engine, the Fracture Resistant Screw 3692202 plays a pivotal role in securing critical components. Its design helps to mitigate the risk of screw failure under operational stresses, thereby enhancing the engine’s durability.

QSG12 CM2880 G112 and QSG12/X12 CM2350 G110

The QSG12 CM2880 G112 and QSG12/X12 CM2350 G110 engines also utilize the Fracture Resistant Screw 3692202. This screw is essential in maintaining the integrity of the engine’s mounting and structural components, ensuring consistent performance and reliability.

X11 CM2670 X126B and X12 CM2350 X119B

In the X11 CM2670 X126B and X12 CM2350 X119B engines, the Fracture Resistant Screw 3692202 is used to secure various engine components. Its design helps to prevent screw failure, which could otherwise lead to significant engine damage.

X12 CM2670 X121B and X12N CMMDG1 X143B

For the X12 CM2670 X121B and X12N CMMDG1 X143B engines, the Fracture Resistant Screw 3692202 is a critical component. It is used in areas of the engine where screws are subject to high stress, ensuring that the engine can operate safely and efficiently.

X13 CM2670 X122B

The X13 CM2670 X122B engine also incorporates the Fracture Resistant Screw 3692202. This screw is essential for securing components that are prone to stress fractures, thereby maintaining the engine’s structural integrity and performance.

Role in Engine Systems

In the intricate dance of engine components, the Fracture Resistant Screw 3692202 plays a significant role in ensuring the seamless operation and durability of several key elements. This screw is integral to the assembly and functionality of the camshaft, cylinder head, injectors, rocker levers, and rocker arms.

Camshaft and Cylinder Head Assembly

The camshaft, a pivotal component in the valve train mechanism, relies on precise mounting to the cylinder head. The Fracture Resistant Screw 3692202 secures the camshaft in place, allowing it to operate smoothly without undue stress. This screw’s fracture resistance ensures that the camshaft remains firmly attached, even under the high stresses and vibrations typical in engine operation.

Injector Mounting

Fuel injectors must be accurately positioned to deliver fuel efficiently into the combustion chamber. The Fracture Resistant Screw 3692202 is used to mount injectors securely to the cylinder head. Its robust design prevents loosening over time, maintaining the injector’s precise alignment and ensuring consistent fuel delivery.

Rocker Lever and Rocker Arm Stability

The rocker levers and rocker arms are essential for transferring motion from the camshaft to the valves. These components experience significant force and movement, making secure attachment paramount. The Fracture Resistant Screw 3692202 is employed to fasten the rocker levers and arms to their respective shafts and pivot points. Its strength and durability help maintain the integrity of the valve train, ensuring reliable valve operation and preventing potential engine misfires.

Conclusion

In summary, the Fracture Resistant Screw 3692202 is a vital component in the assembly and operation of the camshaft, cylinder head, injectors, rocker levers, and rocker arms. Its fracture-resistant properties contribute to the longevity and reliability of these engine systems, facilitating smooth and efficient engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.