This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

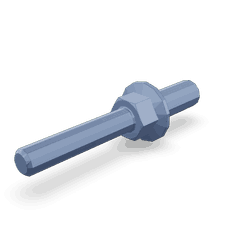

The Studded Flange Cap Screw is a specialized fastener designed for heavy-duty applications, particularly in the automotive and heavy-duty truck industries. Manufactured by Cummins, a renowned name in the production of high-quality automotive components, this screw is engineered to meet the demanding requirements of heavy-duty truck operations. Its robust design and reliable performance make it a valuable component in ensuring the integrity and functionality of truck systems 1.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that combines the features of a stud and a flanged cap screw. It is used to secure components together by threading into a pre-drilled hole and providing a flange that distributes load and prevents over-tightening. This screw operates within mechanical systems by creating a strong, secure connection that can withstand significant stress and vibration, common in heavy-duty truck environments 2.

Purpose of the 3690647 Studded Flange Cap Screw

The 3690647 Studded Flange Cap Screw plays a specific role in the operation of heavy-duty trucks. It is utilized in various truck components where secure fastening is required under high stress and vibration conditions. This includes applications in engine components, transmission systems, and chassis assemblies. Its design ensures that critical components remain firmly attached, contributing to the overall reliability and performance of the truck 3.

Key Features

The 3690647 Studded Flange Cap Screw boasts several key features that enhance its performance. It is constructed from high-strength materials, ensuring durability and resistance to wear. The threading type is designed for optimal engagement with mating components, providing a secure fit. The flange design not only aids in distributing load but also offers a surface for additional fastening elements if required. These features collectively contribute to the screw’s ability to perform under the demanding conditions typical of heavy-duty truck operations 4.

Benefits

Utilizing the 3690647 Studded Flange Cap Screw offers several benefits. Its design provides improved fastening security, ensuring that components remain securely attached even under significant stress and vibration. The screw’s resistance to loosening over time enhances the reliability of truck systems. Additionally, its durability in harsh operating conditions ensures long-term performance, reducing the need for frequent replacements and maintenance 1.

Installation Guidelines

Proper installation of the 3690647 Studded Flange Cap Screw is crucial for optimal performance. It should be installed using the specified torque settings to ensure a secure fit without over-tightening, which could damage the screw or the components being fastened. Special considerations include ensuring the mating surfaces are clean and free of debris to facilitate a proper connection. Following these guidelines will help maintain the integrity and performance of the fastening system 2.

Troubleshooting and Maintenance

Common issues with the 3690647 Studded Flange Cap Screw may include loosening due to vibration or corrosion over time. Regular inspection and maintenance can help identify and address these issues promptly. If loosening is detected, re-tightening to the specified torque settings is recommended. In cases of corrosion, cleaning the affected areas and applying a suitable corrosion-resistant coating can help prevent further degradation 3.

Compatibility and Applications

The 3690647 Studded Flange Cap Screw is designed for use in heavy-duty truck applications. It is compatible with a wide range of truck components, including engine parts, transmission systems, and chassis assemblies. Its versatility and robust design make it suitable for various fastening applications within these systems 4.

Manufacturer Overview - Cummins

Cummins is a leading manufacturer in the automotive industry, known for its commitment to producing high-quality components for heavy-duty trucks. With a rich history of innovation and excellence, Cummins has established a reputation for reliability and performance. The company’s dedication to quality is evident in its products, including the 3690647 Studded Flange Cap Screw, which is designed to meet the rigorous demands of heavy-duty truck operations 1.

Integration of Studded Flange Cap Screw in Cummins Engines

The Studded Flange Cap Screw, part number 3690647, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is integral to the structural integrity and operational efficiency of the engines, ensuring secure fastening of various components.

ISX15 CM2250 SN and QSX15 CM2350 X105

In the ISX15 CM2250 SN and QSX15 CM2350 X105 engines, the Studded Flange Cap Screw is utilized in several key areas. These include securing the engine’s cylinder heads to the engine block, ensuring a tight seal that prevents leaks and maintains the engine’s internal pressure. Additionally, it is used in fastening various ancillary components such as the turbocharger and exhaust manifold, which are essential for the engine’s performance and emissions control 2.

X15 CM2350 X123B

For the X15 CM2350 X123B engine, the Studded Flange Cap Screw plays a similar role. It is employed in securing the cylinder heads, which is crucial for maintaining the engine’s structural integrity and performance. Furthermore, this screw is used in the assembly of other critical components, ensuring that all parts are firmly attached and aligned, which is vital for the engine’s smooth operation and longevity 3.

The use of the Studded Flange Cap Screw in these engines underscores its importance in maintaining the high standards of quality and reliability that Cummins is known for. This part’s design and material ensure that it can withstand the high stresses and temperatures encountered in engine operation, providing a reliable and durable connection 4.

Role of Part 3690647 Studded Flange Cap Screw in Engine Systems

The Part 3690647 Studded Flange Cap Screw is integral to the assembly and functionality of various engine components.

Camshaft Assembly

In the camshaft assembly, the Studded Flange Cap Screw secures the camshaft to the engine block or cylinder head. This ensures precise alignment and stability, which is essential for the camshaft’s role in opening and closing the engine’s valves at the correct times. The screw’s design allows for efficient torque application, maintaining the camshaft’s position under the dynamic forces encountered during engine operation 1.

Engine Oil System

Within the engine oil system, the Studded Flange Cap Screw is often used to attach oil galleries, passages, and filters to the engine block. This secure attachment is vital for maintaining the integrity of the oil flow pathways, ensuring that oil is distributed evenly throughout the engine to lubricate moving parts, cool critical components, and remove contaminants 2.

Engine Cooler Integration

For engines equipped with an engine oil cooler, the Studded Flange Cap Screw plays a role in attaching the cooler to the engine block or oil passages. This secure connection is necessary to maintain the efficiency of the cooling process, which helps in regulating the engine oil temperature. Proper attachment ensures that the cooler can effectively dissipate heat, contributing to the overall performance and longevity of the engine 3.

Conclusion

In summary, the Part 3690647 Studded Flange Cap Screw is a key component in ensuring the structural integrity and functional reliability of critical engine systems, including the camshaft, engine oil system, and engine cooler. Its robust design, reliable performance, and compatibility with various heavy-duty truck components make it an essential part in the assembly and maintenance of Cummins engines 4.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ ↩ ↩ ↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ ↩ ↩ ↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ ↩ ↩ ↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.