3686766

Captive Isolator Cap Screw

Cummins®

IN STOCK

6 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Captive Isolator Cap Screw 3686766 is a specialized component manufactured by Cummins, a prominent figure in the commercial truck industry. This screw is designed for use in commercial trucks, where it plays a significant role in ensuring the efficient operation of various truck systems. Cummins is renowned for its high-quality parts and comprehensive product range, making the 3686766 Captive Isolator Cap Screw a reliable choice for truck maintenance and upgrades.

Basic Concepts

A Captive Isolator Cap Screw is a type of fastener that incorporates an isolator within its design. Its primary function in mechanical systems is to secure components while providing vibration isolation. This isolation helps reduce the transmission of vibrations between connected parts, which can enhance the longevity and performance of the system. The screw operates by threading into a designated hole, where the isolator component absorbs and dampens vibrations 1.

Purpose of the 3686766 Captive Isolator Cap Screw

In the context of a commercial truck, the 3686766 Captive Isolator Cap Screw serves a specific role within the engine or other systems. It is used to secure components that are subject to significant vibrations, such as engine mounts or exhaust system parts. By isolating vibrations, it helps maintain the integrity of the connections and reduces wear on the components, contributing to the overall reliability and performance of the truck 2.

Key Features

The 3686766 Captive Isolator Cap Screw boasts several key characteristics that enhance its performance. Its design includes an integrated isolator made from a durable material, which provides effective vibration damping. The screw itself is typically made from high-strength steel, ensuring it can withstand the rigors of truck operation. Additionally, the screw features a captive design, meaning the isolator remains attached to the screw, simplifying the installation process and reducing the risk of losing the isolator during maintenance 3.

Benefits

Using the 3686766 Captive Isolator Cap Screw offers several advantages. Its vibration isolation properties help protect connected components from excessive wear, leading to improved durability. The screw’s robust construction ensures reliability under demanding conditions, while its captive design streamlines the installation process. Furthermore, by reducing vibrations, the screw can contribute to more efficient truck operations, potentially leading to fuel savings and reduced maintenance costs 4.

Installation Process

Installing the 3686766 Captive Isolator Cap Screw requires careful attention to detail to ensure proper function and longevity. Begin by identifying the correct location for the screw within the truck’s system. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring it is secure without over-tightening, which could damage the isolator or the connected components. It is also important to verify that the isolator is properly seated and functioning as intended upon completion of the installation 5.

Common Issues and Troubleshooting

Typical problems with the 3686766 Captive Isolator Cap Screw may include isolator failure, screw loosening, or damage to the screw or connected components. If the isolator shows signs of wear or failure, it may need to be replaced. Screw loosening can often be addressed by re-tightening to the correct torque specifications. In cases where the screw or components are damaged, replacement may be necessary. Regular inspections during maintenance checks can help identify issues early, allowing for timely repairs or replacements 6.

Maintenance Tips

To ensure the longevity and optimal performance of the 3686766 Captive Isolator Cap Screw, regular maintenance is recommended. Inspect the screw and isolator during routine maintenance checks for signs of wear, damage, or loosening. Ensure that the screw remains tightened to the correct specifications and that the isolator is functioning effectively. Keeping the area around the screw clean and free of debris can also help prevent issues and ensure smooth operation 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice for truck manufacturers and operators worldwide.

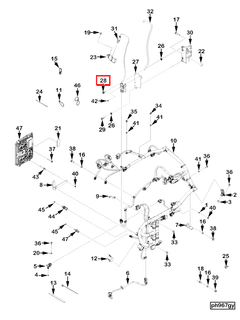

Captive Isolator Cap Screw 3686766 in Cummins Engines

The Captive Isolator Cap Screw 3686766 is a critical component in various Cummins engines, ensuring the stability and integrity of the engine’s mounting system. This part is integral to the engine’s design, providing a secure connection between the engine and its mounting points.

ISX Series Engines

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The Captive Isolator Cap Screw 3686766 is used in the ISX series engines to maintain the structural integrity of the engine mounts. These engines, known for their robust performance, require reliable fastening solutions to withstand the stresses of heavy-duty operations.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2350 X105

In the QSX series engines, the Captive Isolator Cap Screw 3686766 plays a crucial role in securing the engine mounts. These engines are designed for high-performance applications, and the use of this screw ensures that the engine remains securely fastened, even under demanding conditions.

X Series Engines

- X12 CM2350 X119B

- X12 CM2670 X121B

- X13 CM2670 X122B

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X series engines also utilize the Captive Isolator Cap Screw 3686766 to maintain the alignment and stability of the engine mounts. These engines are designed for versatility and durability, and the use of this screw ensures that the engine remains securely attached to the vehicle, providing consistent performance and reliability.

Other Models

- ISG12 CM2880 G107

- QSG12/X12 CM2350 G110

In the ISG and QSG series engines, the Captive Isolator Cap Screw 3686766 is similarly essential for maintaining the structural integrity of the engine mounts. These engines are designed for specific applications, and the use of this screw ensures that the engine remains securely fastened, providing the necessary stability and performance.

Role of Part 3686766 Captive Isolator Cap Screw in Engine Systems

The part 3686766 Captive Isolator Cap Screw is integral to the secure and efficient operation of various engine components. It plays a significant role in the following systems:

Engine Control Module (ECM)

In the engine control module, the captive isolator cap screw ensures that the module is firmly attached to its support structure. This secure attachment is essential for maintaining the integrity of the electrical connections and protecting the sensitive electronic components from vibrations and mechanical stress.

Module Support

The module support system relies on the captive isolator cap screw to maintain a stable and vibration-dampened environment for the ECM. By isolating the module from direct contact with the engine’s vibrations, the screw helps in preserving the accuracy and reliability of the engine’s control signals.

Primer System

Within the primer system, the captive isolator cap screw is used to secure components that are vital for the initial fuel delivery to the engine. This ensures that the primer operates smoothly and consistently, contributing to reliable engine starts, especially in cold conditions.

Fuel System

In the fuel system, the captive isolator cap screw is employed to fasten components such as fuel injectors and sensors. Its role here is to ensure that these components remain securely in place, allowing for precise fuel delivery and monitoring, which are essential for optimal engine performance and fuel efficiency.

Sensor Attachment

Sensors throughout the engine system, such as those monitoring temperature, pressure, and other critical parameters, are often secured using the captive isolator cap screw. This ensures that the sensors remain in the correct position and orientation, providing accurate data to the ECM for precise engine management.

Nitrogen Oxide (NOx) Control

In systems designed to control nitrogen oxide emissions, the captive isolator cap screw is used to secure components like catalytic converters and exhaust gas recirculation (EGR) valves. This secure attachment is vital for the effective operation of these components, ensuring that they can withstand the high temperatures and pressures of the exhaust system while maintaining their functional integrity.

Conclusion

The 3686766 Captive Isolator Cap Screw by Cummins is a vital component in ensuring the secure and efficient operation of various engine systems. Its role in vibration isolation and secure fastening contributes to the longevity and performance of commercial trucks. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, Simon Baseley, SAE International, 2014

↩ -

The Dynamic Behavior of a Diesel Engine, S. A. Miedema, Z. Lu, Published by Drir S. A. Miedema, 2010

↩ -

Diesel Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2014

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

QSK60 CM2350 K121, Bulletin Number 4388648, Fault Code Troubleshooting Manual

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.