3682414

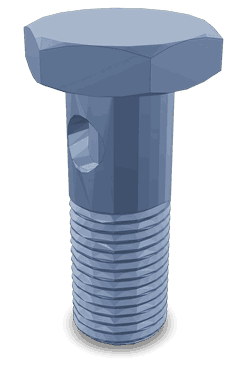

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3682414 Banjo Connector Screw is a component manufactured by Cummins, designed for use in commercial trucks. This article provides an overview of the Banjo Connector Screw, its function, key features, benefits, and maintenance suggestions.

Basic Concepts of Banjo Connector Screw

A Banjo Connector Screw is a type of fitting used in hydraulic and fuel systems to connect hoses or pipes. It typically consists of a bolt, a banjo fitting, and a gasket. The banjo fitting has a curved shape that allows for flexibility in the connection, while the gasket ensures a seal to prevent leaks 1.

Function of the 3682414 Banjo Connector Screw

This Cummins part plays a role in the hydraulic or fuel system of a truck by providing a secure and leak-proof connection between components. It is commonly used in high-pressure systems where reliable sealing is required 2.

Key Features

- Constructed from high-quality materials to withstand high pressures and temperatures.

- Designed with a curved banjo fitting to allow for flexible connections.

- Includes a gasket to ensure a tight seal and prevent leaks.

- Compatible with various hydraulic and fuel system components.

Benefits

- Provides a secure and reliable connection in high-pressure systems.

- The design allows for flexibility in routing hoses and pipes.

- The gasket ensures a leak-proof seal, reducing the risk of system failure.

- Durable construction contributes to the longevity of the connection.

Troubleshooting and Maintenance

- Regular inspection for signs of wear or damage to the banjo fitting and gasket.

- Check for leaks around the connection point and tighten if necessary.

- Replace the gasket if it shows signs of wear or if a leak is detected.

- Ensure that the banjo fitting is properly aligned and seated to maintain a seal.

Cummins Engine Compatibility with Part 3682414

The 3682414 Banjo Connector Screw is a critical component in the fluid systems of various Cummins engines. This part is designed to ensure a secure and leak-proof connection between the banjo fitting and the hose or pipe it attaches to. Here is a detailed look at how this part fits with the listed engines:

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2350 X101

The ISX series engines, with their various configurations, utilize the Banjo Connector Screw to maintain the integrity of the fluid lines that are crucial for the engine’s operation. This part is essential for the cooling system, fuel system, and other fluid pathways that require a robust connection.

ISG and ISM Series Engines

- ISG12 CM2880 G107

- ISM CM876

The ISG and ISM series engines also benefit from the use of the Banjo Connector Screw. These engines, while differing in some specifications, share the need for reliable fluid connections to ensure optimal performance and longevity.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX series engines, known for their high power output and efficiency, incorporate the Banjo Connector Screw in their design. This part is crucial for maintaining the pressure and flow of fluids in these high-performance engines.

X Series Engines

- X15 CM2350 X116B

- X15 CM2450 X134B

The X series engines, with their robust design and high torque capabilities, also rely on the Banjo Connector Screw. This part ensures that the fluid connections can withstand the stresses and demands of these powerful engines.

By using the Banjo Connector Screw in these engines, Cummins ensures that the fluid systems remain secure and leak-free, contributing to the overall reliability and efficiency of the engines 3.

Role of Part 3682414 Banjo Connector Screw in Engine Systems

The 3682414 Banjo Connector Screw is integral to the efficient operation of various engine systems. It facilitates secure connections in the accessory drive system, ensuring that components like the front gear train accessory operate smoothly without fluid leaks.

In the air intake system, this screw plays a part in maintaining a sealed connection at the air intake connection, which is vital for optimal engine performance. It also contributes to the proper arrangement and function of the exhaust recirculation air system, enhancing emissions control.

When it comes to the doser system, the Banjo Connector Screw ensures that the doser fluid is delivered accurately and without interruption, which is essential for the system’s effectiveness in reducing emissions.

Additionally, it is used in the housing of the thermostat, where it helps maintain the integrity of the thermostat’s plumbing, ensuring consistent engine temperature regulation.

In the crankcase breather system, this screw aids in maintaining a sealed environment, which is necessary for the efficient operation of the breather. It also plays a role in the turbocharger’s recirculation and exhaust systems, contributing to the turbocharger’s performance and durability.

Overall, the 3682414 Banjo Connector Screw is a key component in ensuring the reliability and efficiency of these engine systems.

Conclusion

The 3682414 Banjo Connector Screw is a vital component in the hydraulic and fuel systems of Cummins engines. Its design and construction ensure secure, leak-proof connections that are essential for the efficient operation of various engine systems. Regular maintenance and inspection of this part are crucial to prevent leaks and ensure the longevity of the engine’s fluid systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.