3651012

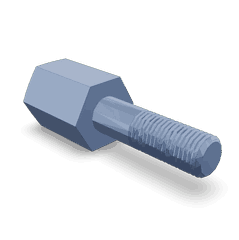

Studded Hexagon Cap Screw

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3651012 Studded Hexagon Cap Screw is a specialized fastener produced by Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry. This screw is designed for use in commercial trucks, where it plays a significant role in securing various components and assemblies. Its robust construction and precise engineering make it suitable for the demanding conditions encountered in truck operations.

Basic Concepts of Studded Hexagon Cap Screws

A studded hexagon cap screw is a type of fastener characterized by a hexagonal head and a threaded shank that extends beyond the nut or tapped hole it secures. This design allows for easy tightening and loosening using a wrench or socket. In mechanical assemblies, these screws are used to join components securely, ensuring stability and integrity under load. They function by converting torque applied to the head into clamping force, which holds the joined parts together 1.

Purpose of the 3651012 Studded Hexagon Cap Screw in Truck Operation

In the context of commercial trucks, the 3651012 Studded Hexagon Cap Screw serves to secure critical components and assemblies. It is commonly used in areas where high tensile strength and resistance to vibration are required, such as in the engine compartment, chassis, and other structural elements. Its role is to maintain the integrity of these assemblies, ensuring that components remain firmly in place under the dynamic conditions of truck operation.

Key Features

The 3651012 Studded Hexagon Cap Screw features a robust design that includes a hexagonal head for easy tool engagement and a shank with precise threading. It is typically made from high-strength materials, such as alloy steel, to provide durability and resistance to wear. The screw’s studded design allows it to extend beyond the nut or tapped hole, offering additional security against loosening due to vibration 2.

Benefits

The benefits of using the 3651012 Studded Hexagon Cap Screw include improved load distribution across the fastened components, enhanced security due to its studded design, and superior resistance to vibration and loosening. These attributes contribute to the overall reliability and longevity of the truck’s mechanical assemblies 3.

Installation Guidelines

Proper installation of the 3651012 Studded Hexagon Cap Screw involves several steps to ensure optimal performance. Begin by cleaning the mating surfaces to remove any debris or corrosion. Use a torque wrench to tighten the screw to the specified torque setting, which ensures the correct clamping force without over-tightening. It is also important to periodically check the screw’s tightness, especially in high-vibration areas, to maintain secure fastening.

Troubleshooting and Maintenance

Common issues with studded hexagon cap screws include loosening due to vibration and corrosion. Regular inspection and maintenance can help identify these problems early. If loosening is detected, re-tighten the screw to the specified torque. In cases of corrosion, cleaning the affected area and applying a suitable anti-corrosion treatment can help prolong the screw’s lifespan.

Compatibility and Applications

The 3651012 Studded Hexagon Cap Screw is designed for use in various commercial truck assemblies. It is compatible with a wide range of components and systems, making it a versatile choice for truck manufacturers and maintenance professionals. Its applications include securing engine components, chassis parts, and other structural elements where high strength and reliability are required.

Safety Considerations

When handling, installing, or maintaining the 3651012 Studded Hexagon Cap Screw, it is important to observe safety guidelines to protect personnel and ensure the integrity of the truck. Use appropriate personal protective equipment (PPE), such as gloves and safety glasses, to prevent injury. Follow the manufacturer’s torque specifications to avoid over-tightening, which can lead to damage or failure of the screw or the fastened components.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality automotive components, including fasteners like the 3651012 Studded Hexagon Cap Screw. The company’s expertise in engine manufacturing and commitment to innovation ensure that its products meet the rigorous demands of commercial truck applications.

Role of Part 3651012 Studded Hexagon Cap Screw in Various Engine Systems

Plumbing Systems

In plumbing systems integrated with engine components, the 3651012 Studded Hexagon Cap Screw is utilized to secure fittings and connections. This ensures that the plumbing remains intact under varying pressure conditions, which is essential for the reliable transfer of fluids within the engine system. The screw’s design allows for a secure fit that resists loosening over time, maintaining the integrity of the plumbing network.

Turbocharger Coolant Systems

Within turbocharger coolant systems, the 3651012 Studded Hexagon Cap Screw plays a significant role in attaching coolant passages and heat exchanger components. It ensures that the coolant flow is uninterrupted, which is vital for dissipating heat generated by the turbocharger. The screw’s robust construction helps withstand the thermal stresses and pressure fluctuations inherent in such systems.

Turbocharger Oil Systems

In turbocharger oil systems, the 3651012 Studded Hexagon Cap Screw is employed to fasten oil feed and return lines, as well as to secure oil filters and other critical components. This ensures a consistent oil supply to lubricate moving parts within the turbocharger, enhancing its efficiency and longevity. The screw’s hexagonal head allows for easy tightening and removal, facilitating maintenance procedures.

Conclusion

The 3651012 Studded Hexagon Cap Screw is a critical component in the operation and maintenance of commercial trucks. Its robust design, high-strength materials, and precise engineering make it an essential fastener for securing various engine and structural components. Proper installation, regular maintenance, and adherence to safety guidelines are vital to ensure the longevity and reliability of this Cummins part in demanding truck applications.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.