This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3613041 Breakoff Screw is a specialized component designed for use in heavy-duty truck maintenance and operation. This screw plays a specific role in ensuring the proper functioning of certain truck systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining high performance standards in heavy-duty truck fleets.

Purpose and Function

The Cummins 3613041 Breakoff Screw serves a distinct function within the operation of a truck. It is primarily used in applications where a secure, yet temporary fastening is required. Once the screw has fulfilled its role, it is designed to break off at a predetermined torque, ensuring that the fastened components remain in place without the risk of over-tightening. This feature is particularly useful in applications where access to the fastening point may be limited after initial installation 1.

Key Features

The Cummins 3613041 Breakoff Screw is characterized by several key features that enhance its functionality and reliability. Its design incorporates a break-off point that ensures the screw will shear at a specific torque level, preventing damage to the components it secures. The screw is manufactured from high-strength materials, ensuring durability under the demanding conditions typical of heavy-duty truck applications. Additionally, its unique design allows for easy installation and reliable performance 2.

Benefits

Utilizing the Cummins 3613041 Breakoff Screw offers several advantages in heavy-duty truck applications. The screw’s design contributes to improved performance by ensuring components are securely fastened without the risk of over-tightening. Its durability and reliability make it a preferred choice for applications where maintenance access is limited. Furthermore, the break-off feature simplifies the installation process, reducing the time and effort required for maintenance tasks 3.

Installation Process

Installing the Cummins 3613041 Breakoff Screw requires attention to detail to ensure a secure fit. The process involves selecting the appropriate torque setting to achieve the break-off point, using a torque wrench for precision. It is important to follow manufacturer guidelines for installation to ensure the screw functions as intended. Proper alignment and seating of the screw are crucial for optimal performance.

Common Issues and Troubleshooting

Common issues associated with the Cummins 3613041 Breakoff Screw may include improper installation leading to either premature break-off or failure to break off at the desired torque. Troubleshooting these issues involves checking the installation process, ensuring the correct torque settings were used, and verifying that the screw was properly aligned and seated. Addressing these issues promptly can prevent further complications and ensure the continued reliability of the fastening.

Maintenance Tips

Routine maintenance of the Cummins 3613041 Breakoff Screw is minimal due to its design. However, periodic inspection is recommended to ensure the screw has not loosened or become damaged. Replacement guidelines suggest that if the screw has broken off as designed, no further action is required unless the fastening point needs to be accessed again. In such cases, a new screw should be installed following the proper procedures.

Safety Considerations

When working with the Cummins 3613041 Breakoff Screw, it is important to follow safety precautions to prevent accidents or injuries. This includes using the correct tools for installation and ensuring that all safety guidelines provided by the manufacturer are followed. Proper handling of the screw and awareness of its break-off feature are crucial to maintaining a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality components for heavy-duty trucks, ensuring reliability, performance, and durability in demanding applications. The company’s dedication to innovation and excellence is reflected in its wide range of products, including the Cummins 3613041 Breakoff Screw.

Compatibility with Cummins Engines

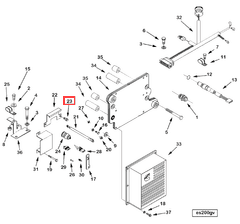

The Breakoff Screw, identified by part number 3613041 and manufactured by Cummins, is a critical component that fits into several of their engine models. This part is essential for securing various parts within the engine assembly, ensuring that the engine operates smoothly and efficiently.

L10 Engines

For the L10 series engines, the Breakoff Screw is compatible with both the L10 CELECT and L10 MECHANICAL variants. This screw plays a vital role in maintaining the structural integrity of the engine by securing components that are subject to high stress and vibration. Its placement is crucial for the overall performance and longevity of the engine.

N14 Engines

Similarly, the Breakoff Screw is also compatible with the N14 series engines, including both the N14 CELECT and N14 MECHANICAL models. In these engines, the screw is used to fasten parts that are integral to the engine’s operation, ensuring that they remain securely in place under various operating conditions.

Grouping by Engine Type

When considering the compatibility of the Breakoff Screw across different engine types, it is important to note that the part number 3613041 is designed to fit seamlessly into both the L10 and N14 series engines. This compatibility allows for easier maintenance and repair processes, as technicians can use the same part across multiple engine models, reducing the need for specialized parts inventory.

Application Across Models

The Breakoff Screw’s application across the L10 and N14 engines highlights its versatility and importance in Cummins’ engine design. By ensuring that this part fits into both CELECT and MECHANICAL variants, Cummins demonstrates a commitment to standardization and efficiency in their engine manufacturing processes.

Role of Part 3613041 Breakoff Screw in Engine Systems

The Breakoff Screw, identified as part 3613041, is integral to the secure and reliable operation of various engine components. It ensures that connections remain intact under operational stress, thereby maintaining the integrity of the engine’s electronic and mechanical systems.

Actuator Harness

In the actuator harness, the Breakoff Screw plays a significant role in securing electrical connections. This ensures that the harness remains firmly attached to the actuator, preventing any disconnections that could lead to malfunctions in the engine’s operation. Reliable connections are essential for the consistent transmission of signals and power, which are vital for the actuator’s performance.

Harness Mounting Actuator

For the harness mounting actuator, the Breakoff Screw is used to anchor the harness to the actuator securely. This is important for maintaining the structural integrity of the harness, especially under vibration and movement typical in engine environments. A secure mount prevents potential damage to the harness and ensures that the actuator receives a stable and uninterrupted power supply.

Pace Control System

Within the pace control system, the Breakoff Screw is employed to ensure that all electrical connections are maintained under varying operational conditions. This system relies on precise control signals, and any loose connection could result in erratic performance. The Breakoff Screw helps in maintaining a stable connection, thus ensuring the system operates smoothly and efficiently.

Electronic Engine Control System

In the electronic engine control (EEC) system, the Breakoff Screw is critical for securing various sensors and control modules. These components need to communicate effectively with the engine control unit (ECU) to ensure optimal engine performance. The Breakoff Screw ensures that these connections remain secure, preventing any signal loss or interference that could affect engine operation.

ETR Control

For the ETR (Electronic Throttle Control) system, the Breakoff Screw is used to secure the throttle switch lever and other related components. This ensures that the throttle control system operates with precision, allowing for accurate throttle response and engine performance. Secure connections are essential for the reliable operation of the ETR system, which directly impacts the engine’s responsiveness and efficiency.

Throttle Switch Lever

The throttle switch lever, a component of the throttle control system, relies on the Breakoff Screw to maintain secure electrical connections. This is important for ensuring that the throttle position is accurately detected and communicated to the engine control unit. Reliable connections here are essential for maintaining smooth and responsive throttle operation, which is critical for overall engine performance.

Conclusion

The Cummins 3613041 Breakoff Screw is a vital component in the maintenance and operation of heavy-duty trucks. Its unique design and functionality contribute to the secure fastening of components, ensuring the reliability and efficiency of the vehicle. By understanding its purpose, installation process, and compatibility with various Cummins engine models, technicians and fleet managers can ensure optimal performance and longevity of their heavy-duty truck fleets.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, Automotive Systems Principles and Practice (CRC Press, 2011).

↩ -

Frank Sander, Diesel Mechanics, First Edition (Global Media, 2007).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.