3532940

Hexagon Head Set Screw

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Set Screw, specifically Part #3532940 by Cummins, is a vital component in the realm of commercial trucks. This screw is widely utilized for its effectiveness in securing various truck components, ensuring that parts remain firmly in place under operational stress. Its role in maintaining the integrity and functionality of truck assemblies underscores its significance in the commercial trucking industry.

Basic Concepts of Hexagon Head Set Screws

A Hexagon Head Set Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a hex key. The design of the screw, with its threaded shaft, enables it to create a secure connection when driven into a pre-tapped hole. Typically, these screws are made from materials such as stainless steel or alloy steel, chosen for their durability, resistance to corrosion, and ability to withstand high tensile loads. The material properties ensure that the screw maintains its structural integrity and fastening capability over time 1.

Purpose of the 3532940 Hexagon Head Set Screw in Truck Operation

This Cummins part serves a specific function in the operation and maintenance of commercial trucks. It is employed in various truck assemblies where secure fastening is required. Common applications include securing components within the engine compartment, attaching panels, and fastening parts of the chassis. The screw’s design and material ensure that it can withstand the vibrations and stresses inherent in truck operation, thereby contributing to the overall reliability and safety of the vehicle 2.

Key Features of the 3532940 Hexagon Head Set Screw

This part is distinguished by several key features. Its hexagonal head design allows for precise and efficient tightening using a hex key, minimizing the risk of cam-out. The screw boasts a specific thread type that ensures a strong grip within the tapped hole, enhancing its fastening security. Additionally, it may feature special coatings or treatments, such as a zinc plating, to improve corrosion resistance and extend its service life in various environmental conditions 3.

Benefits of Using the 3532940 Hexagon Head Set Screw

Utilizing this Cummins part offers several advantages. The screw provides improved fastening security due to its thread design and material properties, ensuring that components remain securely attached under operational stress. Its resistance to vibration helps maintain the integrity of the fastening over time, reducing the need for frequent re-tightening. Furthermore, the hexagonal head design facilitates ease of installation and removal, allowing for quick and efficient maintenance procedures.

Installation and Usage Guidelines

Proper installation of this part involves several steps to ensure optimal performance. Begin by selecting the appropriate size hex key to match the screw’s head. Insert the screw into the pre-tapped hole and use the hex key to tighten it securely. It is important to adhere to the recommended torque specifications to avoid over-tightening, which could damage the screw or the surrounding material. Using the correct tools and following the specified torque ensures a secure and durable fastening.

Troubleshooting Common Issues

Common issues associated with Hexagon Head Set Screws include loosening due to vibration and corrosion. To address loosening, ensure that the screw is tightened to the correct torque specification during installation. If loosening occurs over time, re-tightening the screw or using a thread-locking compound can help maintain the fastening security. Corrosion can be mitigated by selecting screws with appropriate coatings or treatments, such as zinc plating, and by performing regular inspections to identify and address any signs of corrosion early.

Maintenance Tips

Regular maintenance practices are crucial for ensuring the longevity and effectiveness of this Cummins part. Inspect the screws periodically for signs of loosening, corrosion, or damage. Replace any screws that show signs of wear or failure to maintain the integrity of the fastening. Additionally, keeping the surrounding areas clean and free of debris can prevent contamination that may lead to corrosion or other issues.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer with a rich history in the commercial truck industry. Founded in 1919, Cummins has established itself as a leader in the production of diesel engines, related technologies, and power generation equipment. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial trucks. Cummins is recognized for its commitment to quality, innovation, and customer satisfaction, making it a trusted name in the industry.

Hexagon Head Set Screw 3532940 Compatibility with Cummins Engines

The Cummins Hexagon Head Set Screw part number 3532940 is a versatile component that fits a variety of Cummins engines. This screw is designed to secure various parts within the engine assembly, ensuring stability and reliability. Below is a detailed breakdown of the engines with which this part is compatible:

4B3.9, 6B5.9, 6C8.3, B3.3, B4.5 CM2350 B129B, B5.9 G, B5.9 GAS PLUS CM556, B6.7 CM2670 B153B

These engines, which include both the 4B3.9 and 6B5.9 models, as well as the B3.3 and B4.5 CM2350 B129B, are part of Cummins’ mid-range and larger engine families. The 3532940 screw is used in these engines to secure various components, ensuring that parts remain tightly fastened during operation.

C GAS PLUS CM556, C8.3 G, D4.0 CM2620 D103B, F3.8 CM2620 F137B, F4.5 CM2620 F139B, F4.5 CM2620 F141C

The C GAS PLUS CM556 and C8.3 G engines are part of Cummins’ lineup of gas engines. The 3532940 screw is used in these engines to secure components that require a robust fastening solution. Similarly, the D4.0 CM2620 D103B, F3.8 CM2620 F137B, F4.5 CM2620 F139B, and F4.5 CM2620 F141C engines benefit from this screw’s reliability in maintaining the integrity of their assemblies.

G8.3, ISB CM550, ISB4.5 CM2350 B104, ISB5.9G CM2180, ISBE CM2150, ISBE CM800, ISBE4 CM850

The G8.3 engine, along with the ISB series engines such as the ISB CM550, ISB4.5 CM2350 B104, and ISB5.9G CM2180, are part of Cummins’ diesel engine family. The 3532940 screw is used in these engines to secure various parts, ensuring that the engine operates smoothly and efficiently.

ISC CM554, ISC CM850, ISF2.8 CM2220 F129, ISG12 CM2880 G107

The ISC CM554 and ISC CM850 engines, as well as the ISF2.8 CM2220 F129 and ISG12 CM2880 G107, are part of Cummins’ smaller and medium-sized engine lineup. The 3532940 screw is used in these engines to secure components that require a reliable fastening solution, ensuring the engine’s longevity and performance.

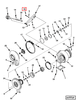

Role of Part 3532940 Hexagon Head Set Screw in Various Engine Components

This part is integral to the assembly and functionality of numerous engine components. Its role is to provide secure fastening, ensuring that parts remain firmly in place under the high stress and dynamic conditions of engine operation.

Turbocharger and Related Components

In turbochargers, the Hexagon Head Set Screw is used to secure the turbine housing to the actuator bracket assembly. This ensures that the turbocharger operates efficiently by maintaining the precise alignment and integrity of the turbine housing and actuator components. Similarly, in aftermarket turbochargers and turbocharger repair kits, this screw plays a key role in securing the housing and ensuring optimal performance.

Exhaust Manifold and Heat Exchanger

For the exhaust manifold kit and heat exchanger, the Hexagon Head Set Screw is essential in securing the manifold to the engine block and the heat exchanger to its mounting points. This secure attachment is vital for maintaining the structural integrity and efficiency of the exhaust system, ensuring that exhaust gases are directed properly and heat is managed effectively.

Fuel Pump and Coupling

In the fuel pump coupling, the Hexagon Head Set Screw is used to fasten the coupling to the fuel pump and engine components. This secure connection is important for the reliable transfer of fuel under pressure, ensuring consistent fuel delivery to the engine.

Wastegate and Actuator Kits

For wastegate actuator kits and wastegate t/housing sub-assemblies, the Hexagon Head Set Screw is employed to secure the actuator to the wastegate housing. This ensures that the wastegate operates correctly, managing turbocharger boost levels and protecting the engine from over-boosting.

Prechamber and Turbine Housing Kits

In prechamber-set turbine housing kits and prechamber-set actuator kits, the Hexagon Head Set Screw is used to secure prechamber components, ensuring they remain in place during engine operation. This is important for the precise combustion process and overall engine performance.

Mounting and Bracket Kits

For mounting kits and turbocharger bracket kits, the Hexagon Head Set Screw provides the necessary fastening to secure the turbocharger and related components to the engine. This ensures that the turbocharger is held firmly in place, reducing the risk of movement or misalignment during operation.

Performance and Aftermarket Parts

In performance parts and aftermarket components, the Hexagon Head Set Screw is often used to enhance the securement of upgraded or modified parts. This is essential for maintaining the performance gains and reliability of these components under high-stress conditions.

Conclusion

The Hexagon Head Set Screw, part 3532940, is a fundamental component in the secure assembly and operation of various engine systems, contributing to the overall efficiency and reliability of the engine. Its robust design, material properties, and compatibility with a wide range of Cummins engines make it an indispensable part in the commercial trucking industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.