This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

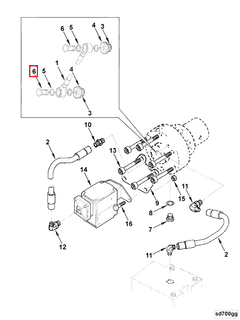

The Cummins 3428599 Banjo Connector Screw is a specialized component designed for use in heavy-duty truck systems. Manufactured by Cummins Inc., a leader in the automotive and diesel engine industry, this banjo connector screw serves a vital role in ensuring the efficient operation of fluid systems within trucks. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, providing reliable performance and durability.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a banjo bolt, a sealing washer, and a banjo fitting. The banjo fitting has a curved shape, resembling a banjo, which allows for flexible connection angles. This design enables the fitting to accommodate movement and vibration, common in automotive and heavy-duty truck applications. The banjo connector screw operates by creating a sealed connection that allows fluid to pass through while preventing leaks 1.

Purpose and Function in Truck Systems

In heavy-duty trucks, the Cummins 3428599 Banjo Connector Screw plays a significant role in the operation of hydraulic and fuel systems. It is used to connect hoses to components such as hydraulic cylinders, fuel injectors, and other fluid-carrying parts. The screw ensures a secure and leak-proof connection, which is crucial for the efficient transfer of fluids under high pressure and temperature conditions. Its application in these systems helps maintain the performance and reliability of the truck’s hydraulic and fuel systems 2.

Key Features

The Cummins 3428599 Banjo Connector Screw is designed with specific features that enhance its performance and durability. It is made from high-quality materials, such as stainless steel, which provide excellent resistance to corrosion and wear. The screw features a precision-machined thread that ensures a tight and secure fit. Additionally, it includes a high-quality sealing washer that provides a reliable seal, preventing fluid leaks. The design of the banjo fitting allows for flexibility in connection angles, accommodating the dynamic movements typical in heavy-duty truck applications 3.

Benefits of Using the 3428599 Banjo Connector Screw

Incorporating the Cummins 3428599 Banjo Connector Screw into truck systems offers several advantages. The high-quality materials and precise manufacturing ensure improved sealing, reducing the risk of fluid leaks. The design of the banjo fitting simplifies installation, allowing for quick and easy connection of hoses. Additionally, the durable construction of the screw facilitates maintenance, as it is less likely to require frequent replacement or repair. These benefits contribute to the overall reliability and efficiency of the truck’s fluid systems 4.

Installation Process

To ensure optimal performance and safety, the Cummins 3428599 Banjo Connector Screw should be installed following specific procedures. Begin by ensuring the mating surfaces are clean and free of debris. Apply a small amount of compatible thread lubricant to the screw threads to facilitate installation and prevent galling. Carefully align the banjo fitting with the component port and slowly tighten the screw using a torque wrench to the manufacturer’s specified torque setting. This ensures a secure connection without over-tightening, which could damage the fitting or the component 5.

Common Issues and Troubleshooting

Typical problems associated with banjo connector screws include fluid leaks, difficulty in installation, and corrosion. To diagnose these issues, inspect the fitting and sealing washer for signs of wear or damage. Ensure that the screw is properly torqued and that the mating surfaces are clean. If a leak is detected, replace the sealing washer or the entire fitting if necessary. Regular inspection and maintenance can help prevent these issues and ensure the continued reliable operation of the connector screw 6.

Maintenance Tips

To prolong the lifespan and ensure consistent performance of the Cummins 3428599 Banjo Connector Screw, regular maintenance practices should be followed. Inspect the fitting and sealing washer during routine maintenance checks for signs of wear or damage. Clean the mating surfaces before reinstallation to prevent contamination. Replace the sealing washer as needed to maintain a reliable seal. Additionally, ensure that the screw is properly torqued during installation to prevent leaks and damage 7.

Safety Considerations

When working with the Cummins 3428599 Banjo Connector Screw, it is important to observe several safety guidelines and precautions. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that the system is depressurized before beginning any work to prevent accidental fluid release. Follow the manufacturer’s torque specifications to avoid over-tightening, which could lead to damage. Additionally, be aware of the high-pressure and high-temperature conditions in which the screw operates, and take appropriate measures to prevent burns or other injuries 8.

Compatibility of Banjo Connector Screw Part 3428599 with Cummins Engines

The Banjo Connector Screw part 3428599 is designed to integrate seamlessly with several Cummins engine models. This part is essential for ensuring a secure and leak-proof connection in hydraulic and fuel systems, which is critical for the overall performance and reliability of the engines.

Grouping of Compatible Engines

QSV81G and QSV91G Engines:

The Banjo Connector Screw part 3428599 is specifically engineered to fit the QSV81G and QSV91G engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications. The screw ensures that the connections within these engines remain tight and secure, preventing any potential leaks that could compromise engine performance.

QSW/QSV82 Engine:

Similarly, the QSW/QSV82 engine also benefits from the use of the Banjo Connector Screw part 3428599. This engine is part of a series that is recognized for its durability and adaptability in various industrial settings. The screw’s design allows for easy installation and maintenance, ensuring that the engine operates smoothly and efficiently.

QSW73 Engine:

The QSW73 engine is another model that is compatible with the Banjo Connector Screw part 3428599. This engine is designed for applications that require a balance of power and efficiency. The screw’s precision fit is crucial for maintaining the integrity of the connections, which is vital for the engine’s overall performance.

Ensuring Compatibility and Performance

When using the Banjo Connector Screw part 3428599 with Cummins engines, it is important to ensure that the screw is properly installed. This involves checking for any damage to the screw or the connection points, as well as ensuring that the screw is tightened to the manufacturer’s specifications. Proper installation is key to maintaining the performance and longevity of the engine 9.

Role of Part 3428599 Banjo Connector Screw in Engine Systems

The 3428599 Banjo Connector Screw is integral to the seamless operation of several engine components. In the assembly adapter, this screw ensures a secure connection, facilitating the transfer of fluids or gases without leaks. Its role becomes particularly significant in the engine monitoring system, where it maintains the integrity of connections that relay vital data about engine performance.

Within the lubricating oil pressure assembly, the 3428599 Banjo Connector Screw is responsible for maintaining consistent oil flow, which is essential for reducing friction and wear on moving parts. Similarly, in the lubricating oil pressure system, it ensures that oil is delivered under the correct pressure to all necessary components, enhancing engine longevity and efficiency.

This component’s ability to provide a reliable seal and connection is fundamental to the effective functioning of these engine systems, underscoring its importance in maintaining overall engine health and performance 10.

Conclusion

The Cummins 3428599 Banjo Connector Screw is a critical component in the operation of heavy-duty truck systems, particularly in hydraulic and fuel systems. Its design, featuring high-quality materials and precision-machined threads, ensures reliable performance and durability. Proper installation and maintenance are essential to maximize the benefits of this part, including improved sealing, simplified installation, and enhanced engine performance. By understanding the role and importance of the 3428599 Banjo Connector Screw, users can ensure the continued reliability and efficiency of their truck’s fluid systems.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Combustion Engine Diagnosis, Rolf Isermann, Springer Vieweg, 2017.

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, Simon Baseley, SAE International, 2014.

↩ -

ISB6.7 G CM2180 B118, Bulletin Number 5411106, Owners Manual.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Combustion Engine Diagnosis, Rolf Isermann, Springer Vieweg, 2017.

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, Simon Baseley, SAE International, 2014.

↩ -

ISB6.7 G CM2180 B118, Bulletin Number 5411106, Owners Manual.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Combustion Engine Diagnosis, Rolf Isermann, Springer Vieweg, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.