3421898

Hexagon Head Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3421898 Hexagon Head Cap Screw is a specialized fastener designed for use in commercial trucks. It is utilized in various mechanical assemblies within these vehicles to secure components effectively. This screw is integral to maintaining the structural integrity and operational efficiency of truck systems.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of bolt characterized by its hexagonal head, which allows for easy tightening and loosening using a wrench or socket. These screws are commonly used in mechanical assemblies to join components securely. They function by converting torque applied to the head into tension along the screw’s axis, which clamps the joined parts together 1.

Purpose and Role in Truck Operation

The Cummins 3421898 Hexagon Head Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is applied in areas where secure fastening is required to withstand significant stress and vibration. This includes engine components, chassis parts, and other critical assemblies where reliability and durability are paramount 2.

Key Features

The Cummins 3421898 Hexagon Head Cap Screw is distinguished by several key features. It is typically made from high-strength materials to ensure durability under demanding conditions. The screw features a specific thread type that provides optimal grip and resistance to loosening. Additionally, its design may include features such as a countersunk head for flush installation or a coating to enhance corrosion resistance 3.

Benefits

Using the Cummins 3421898 Hexagon Head Cap Screw offers several advantages. Its high-strength material composition ensures durability, making it suitable for applications that experience significant stress and vibration. The screw’s design enhances resistance to loosening, contributing to the reliability of the fastened components. Furthermore, the hexagonal head allows for straightforward installation and removal, facilitating maintenance procedures.

Installation Considerations

Proper installation of the Cummins 3421898 Hexagon Head Cap Screw is vital to ensure optimal performance and longevity. It is recommended to use the appropriate torque specifications provided by the manufacturer to achieve the correct clamping force without over-tightening, which could damage the screw or the components being joined. Additionally, ensuring that the mating surfaces are clean and free from debris will enhance the screw’s effectiveness.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening due to vibration and corrosion. Regular inspection and maintenance can help identify and address these issues promptly. If a screw shows signs of loosening, it should be re-tightened to the manufacturer’s specifications. Corrosion can be mitigated by applying a suitable protective coating or lubricant during installation and maintenance.

Safety Considerations

When working with the Cummins 3421898 Hexagon Head Cap Screw, it is important to observe safety guidelines. This includes using the correct tools for installation and removal to avoid damage to the screw or surrounding components. Additionally, ensuring that all safety procedures are followed when performing maintenance on truck systems will help prevent accidents and ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted provider of components for the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 3421898 Hexagon Head Cap Screw, which is designed to meet the rigorous demands of commercial truck applications.

Compatibility with Cummins Engines

The Cummins Hexagon Head Cap Screw part number 3421898 is designed to fit seamlessly with a range of Cummins engines, ensuring robust and reliable fastening. This part is particularly compatible with the following engines:

QSV81G and QSV91G Engines

The 3421898 screw is engineered to provide a secure fastening solution for the QSV81G and QSV91G engines. These engines are known for their durability and efficiency, and the screw’s design complements these attributes by offering high tensile strength and resistance to corrosion.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the 3421898 screw is an ideal choice for various fastening applications. Its precision-engineered threads and robust construction ensure that it can withstand the operational stresses these engines encounter, maintaining the integrity of the assembly over time.

QSW27 and QSW36 Engines

The 3421898 screw is also compatible with the QSW27 and QSW36 engines. These engines benefit from the screw’s ability to provide a tight and secure fit, which is crucial for maintaining the alignment and stability of engine components. The screw’s design ensures that it can handle the mechanical loads and environmental conditions these engines face.

QSW73 Engines

Lastly, the 3421898 screw is suitable for use with the QSW73 engines. Its compatibility with this engine model ensures that it can be used in various fastening applications, providing the necessary strength and durability to keep engine components securely fastened.

Role in Engine Systems

The Cummins 3421898 Hexagon Head Cap Screw is integral to the secure assembly and operation of various engine components. Its application spans across multiple systems, ensuring the integrity and efficiency of the engine’s performance.

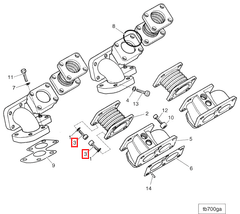

Air Assembly Cleaner

In the air assembly cleaner, the Hexagon Head Cap Screw is used to fasten the cleaner housing to the engine frame. This secure attachment ensures that the air intake system remains sealed, preventing any air leaks that could affect engine performance and fuel efficiency.

Turbocharger Arrangement

Within the turbocharger arrangement, the Hexagon Head Cap Screw plays a role in securing the turbocharger to the exhaust manifold. This attachment is vital for maintaining the structural integrity of the turbocharger, allowing it to operate efficiently under high-pressure conditions.

Assembly Bellows

The assembly bellows, which are flexible components used to connect various parts of the engine, rely on the Hexagon Head Cap Screw for secure attachment. This ensures that the bellows can withstand the thermal expansion and contraction without compromising the seal or connection.

Bracket Filter Assembly

In the bracket filter assembly, the Hexagon Head Cap Screw is employed to mount the filter housing to the engine bracket. This secure mounting is essential for maintaining the filter’s position and ensuring that it functions correctly to clean the air entering the engine.

Exhaust Assembly Manifold

The exhaust assembly manifold utilizes the Hexagon Head Cap Screw to attach the manifold to the engine block. This secure connection is necessary to maintain the integrity of the exhaust system, ensuring that exhaust gases are efficiently directed away from the engine.

Manifold Exhaust Assembly

Finally, in the manifold exhaust assembly, the Hexagon Head Cap Screw is used to fasten the manifold to the exhaust pipes. This ensures a tight seal, preventing exhaust leaks that could lead to decreased engine performance and increased emissions.

Throughout these applications, the Hexagon Head Cap Screw provides the necessary strength and reliability to maintain the structural integrity and operational efficiency of the engine systems.

Conclusion

The Cummins 3421898 Hexagon Head Cap Screw is a critical component in the assembly and maintenance of commercial truck engines. Its high-strength material, precise design, and compatibility with various Cummins engines make it an essential fastener for ensuring the reliability and durability of truck systems. Proper installation, regular maintenance, and adherence to safety guidelines are vital for maximizing the performance and longevity of this Cummins part.

-

Haoran Hu, Rudy Smaling, Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Konrad Reif. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Haoran Hu, Simon J Baseley and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.