This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3421409 Socket Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty applications. This part is integral to the assembly and maintenance of various components within commercial trucks, ensuring reliable performance and durability.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by a hexagonal socket in the head, allowing it to be driven using a hex key. These screws are commonly used in mechanical assemblies due to their high strength and resistance to loosening. They function by providing a secure and tight connection between components, which is vital in systems where vibrations and dynamic loads are present 1.

Purpose of the 3421409 Socket Head Cap Screw in Trucks

This Cummins part plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various areas within the truck’s structure and components, such as engine mounts, chassis assemblies, and other critical junctions where strong and durable fastening is required. Its design ensures that it can withstand the rigors of heavy-duty use, contributing to the overall reliability and safety of the vehicle 2.

Key Features

The 3421409 Socket Head Cap Screw boasts several key features that enhance its performance and durability. It is composed of high-strength materials, typically alloy steel, which provides excellent tensile strength and resistance to wear. The screw’s design includes a countersunk head that allows it to sit flush with or below the surface of the material being fastened, reducing the risk of snagging and improving the aesthetic appearance of the assembly. Additionally, it may feature a corrosion-resistant coating to protect against environmental factors that could compromise its integrity over time 3.

Benefits

Using this part offers several benefits. Its high fastening strength ensures that components remain securely attached, even under significant stress and vibration. The screw’s design facilitates ease of installation, allowing for quick and efficient assembly. Furthermore, its resistance to wear and corrosion enhances the longevity of the fastener, reducing the need for frequent replacements and maintenance.

Installation and Usage

Proper installation of the 3421409 Socket Head Cap Screw is crucial for ensuring its effectiveness. It is recommended to use the appropriate torque specifications provided by the manufacturer to achieve the correct clamping force without over-tightening, which could damage the screw or the components being fastened. The use of a hex key or socket wrench is advised for installation, ensuring that the screw is driven evenly and securely.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws, such as loosening or corrosion, can be addressed through regular inspection and maintenance. If a screw shows signs of loosening, it should be re-tightened to the specified torque. Corrosion can be prevented by ensuring that the screw is clean and dry before installation and by applying a suitable anti-corrosion treatment if necessary. Regular maintenance checks will help identify any issues early, ensuring the continued reliability of the fastening.

Safety Considerations

When working with Socket Head Cap Screws, it is important to observe safety considerations to protect both the operator and the equipment. Proper handling and storage of the screws are necessary to prevent damage and ensure they remain clean and free from contaminants. When in use, operators should wear appropriate personal protective equipment (PPE) and follow all safety guidelines provided by the manufacturer to avoid injury and ensure the safe operation of the vehicle.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the needs of heavy-duty applications. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name among fleet operators and maintenance professionals.

Socket Head Cap Screw 3421409 in Cummins Engines

This part is a critical component in several of Cummins’ engine models. It is integral to the assembly and maintenance of the engines, ensuring secure fastening and structural integrity.

QSB7 CM2880 B117

In the QSB7 CM2880 B117 engine, the 3421409 is used in various applications where secure fastening is essential. This includes securing engine components, ensuring that parts remain tightly fastened under operational stresses.

QSW/QSV82, QSW27, QSW36, QSW73

For the QSW/QSV82, QSW27, QSW36, and QSW73 engines, the 3421409 serves similar purposes. It is employed in the assembly of engine components, providing the necessary strength and reliability to maintain the engine’s structural integrity. This screw is particularly important in areas where vibration and operational stresses are high, ensuring that the engine components remain securely fastened throughout the engine’s lifecycle.

The use of the 3421409 across these engines highlights its versatility and importance in Cummins’ engine designs. This part is a testament to Cummins’ commitment to quality and reliability, ensuring that their engines perform optimally under various conditions.

Role of Part 3421409 in Engine Systems

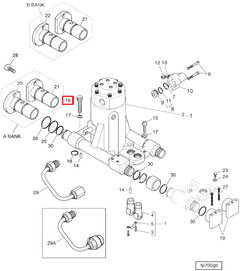

The Socket Head Cap Screw, identified by part number 3421409, is integral to the assembly and operation of various fuel injection components within engine systems. This screw is commonly utilized in securing and maintaining the structural integrity of the fuel injection assembly pump, ensuring that all components remain aligned and function as intended.

In the fuel injection pump, this part plays a significant role in fastening the pump housing to its mounting surface. This secure attachment is essential for the pump to operate under the high pressures and stresses encountered during fuel delivery.

Similarly, within the fuel injection pump assembly, this screw is employed to connect various sub-components, such as the pump body and the drive mechanism. Its use ensures that the assembly remains compact and robust, capable of withstanding the dynamic forces at play.

For the fuel injector assembly pump, the Socket Head Cap Screw is vital in attaching the injector nozzle to the pump body. This connection is paramount for precise fuel delivery, as any misalignment can lead to inefficiencies in fuel atomization and combustion.

In summary, the Socket Head Cap Screw (part 3421409) is a fundamental fastening element across multiple fuel injection components. Its reliable performance ensures the structural stability and operational efficiency of the fuel injection system, contributing to the overall performance and reliability of the engine.

Conclusion

The 3421409 Socket Head Cap Screw is a critical component in the assembly and maintenance of commercial trucks and Cummins engines. Its high-strength design, resistance to wear and corrosion, and ease of installation make it an essential fastener for heavy-duty applications. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for ensuring the continued reliability and performance of this part in demanding environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.