This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3420601 Crosshead Adjusting Screw is a critical component in heavy-duty truck engines, designed to facilitate precise adjustments within the engine’s crosshead mechanism. This ensures optimal performance and efficiency, maintaining the mechanical integrity and operational effectiveness of the engine 1.

Basic Concepts and Functionality

The Crosshead Adjusting Screw operates by fine-tuning the alignment and movement of the crosshead within the engine. This adjustment is essential for the smooth operation of the piston and connecting rod assembly. By allowing for minor adjustments, the screw helps maintain the correct clearances and alignments, which are vital for the engine’s overall performance and longevity 2.

Purpose and Role

The primary role of the Cummins 3420601 Crosshead Adjusting Screw is to enable the fine-tuning of the crosshead’s position in relation to the piston and connecting rod. This adjustment ensures that the engine operates within its designed parameters, aiding in maintaining optimal engine performance. Proper adjustment helps reduce unnecessary wear and tear on engine components, leading to enhanced durability and efficiency 3.

Key Features

The Cummins 3420601 Crosshead Adjusting Screw is characterized by its robust design and the use of high-quality materials. These features ensure that the screw can withstand the high stresses and temperatures encountered in heavy-duty truck engines. Its design allows for easy adjustment, which is crucial for maintenance and repair procedures. Additionally, the screw’s construction includes features that enhance its functionality and reliability in demanding engine environments 4.

Benefits

Utilizing the Cummins 3420601 Crosshead Adjusting Screw offers several benefits. These include improved engine efficiency through precise adjustments, reduced wear and tear on engine components due to optimal alignment, and enhanced durability of the engine as a whole. The screw’s design and materials contribute to these benefits, making it a valuable component in the maintenance and operation of heavy-duty truck engines 5.

Installation and Usage

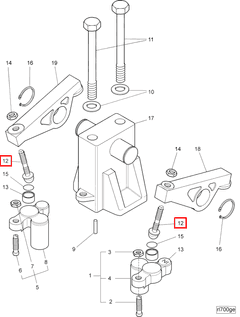

Proper installation of the Cummins 3420601 Crosshead Adjusting Screw involves following specific instructions to ensure it is correctly positioned and tightened. This process may include preliminary checks to ensure the engine is in the correct state for adjustment, followed by the careful turning of the screw to achieve the desired alignment. It is important to adhere to any specific instructions or precautions provided to avoid damaging the engine or the screw itself 6.

Troubleshooting and Maintenance

Common issues with the Cummins 3420601 Crosshead Adjusting Screw may include difficulty in adjustment or signs of wear. Troubleshooting these issues involves checking the screw’s position and condition, and making necessary adjustments or replacements as needed. Regular maintenance practices, such as periodic checks and adjustments, can help ensure the longevity and optimal performance of the screw and the engine it serves 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to providing high-quality, reliable products. The company’s dedication to excellence is evident in its range of engine components, including the Cummins 3420601 Crosshead Adjusting Screw, which is designed to meet the demanding requirements of heavy-duty truck engines 8.

Compatibility with Cummins Engines

The Crosshead Adjusting Screw, identified as part number 3420601, is a critical component in the maintenance and operation of several Cummins engines. This part is designed to fit seamlessly into the engine’s architecture, ensuring precise adjustments and optimal performance.

Cummins QSV81G and QSV91G Engines

For the Cummins QSV81G and QSV91G engines, the Crosshead Adjusting Screw is integral to the engine’s crosshead mechanism. This screw allows for fine-tuning of the piston’s clearance, ensuring that the engine operates smoothly and efficiently. Its placement is crucial for maintaining the correct clearance between the piston and the cylinder walls, preventing wear and potential engine damage 9.

Cummins QSW/QSV82 and QSW27 Engines

In the Cummins QSW/QSV82 and QSW27 engines, the Crosshead Adjusting Screw plays a similar role. It is essential for adjusting the crosshead’s position, which directly affects the piston’s operation. This screw ensures that the piston moves within the cylinder with minimal friction, contributing to the engine’s overall reliability and longevity. The precise fit of this part is vital for maintaining the engine’s performance standards 10.

Cummins QSW36 and QSW73 Engines

The Cummins QSW36 and QSW73 engines also benefit from the Crosshead Adjusting Screw. This component is used to make necessary adjustments to the crosshead, ensuring that the piston operates correctly within the cylinder. The screw’s design allows for easy and accurate adjustments, which is crucial for the engine’s efficiency and durability. Its compatibility with these engines ensures that the engines can be maintained and operated with confidence 11.

Role in Engine Systems

The Crosshead Adjusting Screw (part 3420601) is integral to the precise operation of several key components within engine systems. It ensures optimal alignment and functionality of the lever and rocker mechanisms, which are essential for efficient engine performance.

Interaction with Lever and Rocker Mechanisms

- Lever: The Crosshead Adjusting Screw interacts directly with the lever, allowing for fine-tuned adjustments that maintain the correct tension and alignment. This ensures that the lever operates smoothly, minimizing wear and enhancing the durability of the engine.

- Rocker: Similarly, the screw plays a significant role in the operation of the rocker. By providing adjustable support, it helps in maintaining the rocker’s position relative to other components, which is vital for consistent valve operation and overall engine efficiency.

Assembly and Support Functions

- Lever Assembly Rocker: In assemblies where the lever and rocker are combined, the Crosshead Adjusting Screw facilitates the integration of these components. It allows for micro-adjustments that are necessary to achieve the perfect balance between the lever and rocker, ensuring seamless interaction during engine operation.

- Rocker Assembly Lever: Conversely, in configurations where the rocker assembly includes a lever, the screw enables precise tuning. This is particularly important in high-performance engines where even minor misalignments can lead to significant inefficiencies.

- Rocker Lever Support: The screw also provides essential support to the rocker lever, ensuring that it remains stable under varying operational conditions. This stability is crucial for maintaining consistent valve timing and pressure, directly influencing the engine’s power output and fuel efficiency.

Conclusion

In summary, the Crosshead Adjusting Screw (part 3420601) is a key component in the intricate dance of engine mechanics, ensuring that levers and rockers operate in harmony for optimal engine performance. Its precise fit and function are essential for the smooth operation of the engine’s crosshead mechanism, contributing to the overall efficiency and durability of Cummins engines.

-

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5676938, Engine: 6.7N CM2380 D109B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.