This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

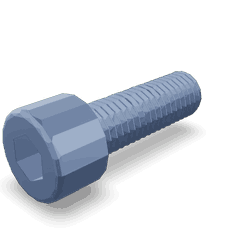

The 3336460 Socket Head Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is significant in commercial truck applications due to its robust design and reliable performance, contributing to the overall efficiency and durability of truck operations 2.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by a hexagonal socket in the head, allowing it to be driven using a hex key. In the automotive industry, these screws are commonly used for their strength and ease of installation. Mechanically, they function by converting torque applied by a hex key into clamping force, securing components together effectively 1.

Purpose of the 3336460 Socket Head Cap Screw in Truck Operations

The 3336460 Socket Head Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various applications within the truck, such as securing engine components, attaching body panels, and fastening chassis parts. Its design ensures a strong and secure connection, which is vital for the safe and efficient operation of the vehicle 2.

Key Features

The 3336460 Socket Head Cap Screw is crafted from high-quality materials, ensuring durability and resistance to wear and corrosion. Its design includes a hexagonal socket for easy installation and removal, and the screw head is designed to distribute clamping force evenly across the fastened components. These features contribute to the screw’s performance and longevity in demanding truck applications 2.

Benefits

Using the 3336460 Socket Head Cap Screw offers several advantages. It provides improved fastening strength, ensuring components remain securely attached under various operating conditions. The ease of installation with a hex key reduces assembly time and effort. Additionally, its resistance to corrosion and wear enhances the screw’s durability, making it a reliable choice for commercial truck applications 2.

Installation Guidelines

To ensure optimal performance and longevity of the 3336460 Socket Head Cap Screw, follow these installation guidelines:

- Select the appropriate size hex key for the screw.

- Align the screw with the designated hole in the components to be fastened.

- Insert the hex key into the screw’s socket and turn clockwise to drive the screw into place.

- Continue tightening until the desired clamping force is achieved, being careful not to overtighten 2.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws may include loosening over time or corrosion. To address these, regularly inspect screws for signs of wear or loosening and tighten as necessary. In cases of corrosion, consider replacing the screw to maintain the integrity of the fastening. Proper maintenance will help prolong the life of the screw and ensure continued reliable performance 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted partner for commercial truck operators worldwide 2.

Socket Head Cap Screw 3336460 in Cummins Engines

The Socket Head Cap Screw part number 3336460, manufactured by Cummins, is a critical component in various Cummins engine models. This screw is integral in securing different parts within the engine assembly, ensuring structural integrity and operational efficiency 2.

L8.9G, CMOH2.0, L125B, QSV81G, QSV91-G4

In the L8.9G, CMOH2.0, L125B, QSV81G, and QSV91-G4 engines, the 3336460 screw is used to fasten components that require precise alignment and stability. These engines are typically found in heavy-duty applications, where durability and reliability are paramount. The screw’s design ensures that the fastened parts can withstand the high stresses and vibrations inherent in these environments 2.

CM558/CM700, V102, QSV91G, QSW/QSV82

For the CM558/CM700, V102, QSV91G, and QSW/QSV82 engines, the 3336460 screw plays a similar role in maintaining the structural integrity of the engine. These engines are often used in industrial and marine applications, where the screw’s ability to secure parts under varying conditions is crucial. The use of this screw in these engines highlights Cummins’ commitment to providing high-quality components that meet the demands of diverse operational settings 2.

QSW27, QSW36, QSW73, QSZ90

The QSW27, QSW36, QSW73, and QSZ90 engines also benefit from the use of the 3336460 screw. These engines are designed for specific applications, and the screw’s role in these models is to ensure that all components are securely fastened, contributing to the overall performance and longevity of the engine. The precision engineering of the screw ensures that it can handle the unique stresses and requirements of these specialized engines 2.

By integrating the 3336460 Socket Head Cap Screw into these various engine models, Cummins demonstrates a consistent approach to quality and reliability across its product line. This screw is a testament to Cummins’ dedication to providing components that enhance the performance and durability of their engines 2.

Role of Part 3336460 Socket Head Cap Screw in Various Engine Components

The part 3336460 Socket Head Cap Screw is integral to the assembly and functionality of numerous engine components. Its applications span across a wide array of systems, ensuring secure fastening and reliable operation. Below is an overview of its role in several key components:

Air Start S/A Accessories

In air start systems and accessories, the Socket Head Cap Screw secures components that facilitate the pneumatic starting of engines, ensuring that all parts remain firmly in place under operational stress 2.

Assembly Flange

For assembly flanges, this screw plays a vital role in attaching the flange to the engine block or other components, providing a stable connection that is essential for the integrity of the assembly 2.

Assembly Ignition

Within ignition assemblies, the screw is used to fasten ignition components, ensuring that the ignition system remains securely attached and functions correctly during engine operation 2.

Cover Components

Covers, such as those for the fuel pump and hotbox assembly, rely on the Socket Head Cap Screw to maintain a sealed and secure environment, protecting internal components from external contaminants 2.

Electronic Control Engine and Engine Control Module

In electronic control systems, including the engine control module, this screw ensures that circuit boards and other sensitive components are properly mounted, contributing to the reliable performance of the engine’s electronic systems 2.

Engine Coolant Vent and Engine Oil Cooler

For the engine coolant vent and oil cooler, the screw secures vents and cooler components, ensuring efficient heat dissipation and maintaining the optimal operating temperature of the engine 2.

Exhaust Assembly Manifold

In the exhaust assembly manifold, the screw fastens manifold components, ensuring a tight seal that prevents exhaust leaks and maintains efficient exhaust flow 2.

Fuel Injector Pump Assembly Cover

The fuel injector pump assembly cover is secured using this screw, ensuring that the cover remains intact and the fuel injection system operates within specified parameters 2.

Gear and Camshaft Housing Assembly

For gear and camshaft housing assemblies, the screw provides a robust fastening solution, ensuring that gears and camshafts are held in precise alignment for smooth engine operation 2.

Housing Assembly Thermostat

In thermostat housing assemblies, the screw secures the thermostat housing, contributing to the accurate regulation of engine temperature 2.

Ignition Assembly and Lubricating Oil Assembly Filter

Both ignition assemblies and lubricating oil assembly filters use this screw to ensure that components are tightly secured, promoting reliable ignition and effective oil filtration 2.

Module Engine Control and Module Fuel Control

Engine control and fuel control modules depend on this screw for secure mounting, ensuring that these critical modules function correctly and contribute to overall engine performance 2.

Oil Cooler and Oil Level Regulation Assembly

The oil cooler and oil level regulation assembly utilize this screw to maintain secure connections, ensuring efficient oil cooling and precise oil level management 2.

Pump Water and Single Assembly Mounting

Water pumps and single assembly mountings rely on the screw to ensure that components are firmly attached, contributing to the reliable operation of these systems 2.

Thermostat Equipment Housing, Thermostat Housing Cover, and Thermostat Housing Mounting

These thermostat-related components are secured using the screw, ensuring that the thermostat housing remains intact and functions correctly to regulate engine temperature 2.

Vent Engine Coolant

Finally, in the vent engine coolant system, the screw ensures that vent components are securely fastened, promoting efficient coolant circulation and temperature management 2.

Conclusion

The 3336460 Socket Head Cap Screw is a vital component in the operation and maintenance of commercial trucks and Cummins engines. Its robust design, ease of installation, and resistance to wear and corrosion make it an essential part for securing various engine components. By ensuring secure fastening and reliable operation, this Cummins part contributes significantly to the overall performance and durability of truck and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.