This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

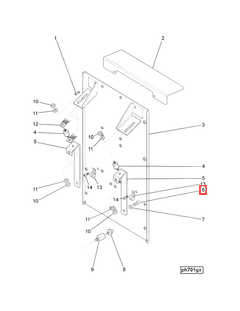

The Socket Head Cap Screw 3336452, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of components that contribute to the efficiency and reliability of heavy-duty vehicles. This part is integral to various mechanical assemblies within these trucks, ensuring secure and durable connections.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for easy installation and removal using a hex key. These screws are commonly used in mechanical assemblies where a flush surface is desired, or where the screw head needs to be countersunk. They provide a strong, permanent fastening solution and are often used in applications requiring high torque and resistance to loosening 1.

Purpose of Socket Head Cap Screw 3336452 in Truck Operations

This part plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various components where secure fastening is crucial, such as engine mounts, chassis assemblies, and other critical areas. Its design ensures that it can withstand the vibrations and stresses encountered in heavy-duty truck operations, maintaining the integrity of the assembly over time 2.

Key Features of Socket Head Cap Screw 3336452

This part is engineered with several design elements and material properties that make it suitable for heavy-duty applications. It is typically made from high-strength steel, which provides the necessary tensile strength and durability. The screw features a precise hexagonal socket that allows for efficient torque application, reducing the risk of cam-out during installation. Additionally, the cap screw is designed with a countersunk head to minimize protrusion and enhance the aesthetic and functional aspects of the assembly.

Benefits of Using Socket Head Cap Screw 3336452

This part offers several advantages for commercial truck applications. Its high-strength material ensures durability under demanding conditions, while the hexagonal socket design facilitates easy and secure installation. The countersunk head provides a flush surface, reducing the risk of damage to adjacent components and improving the overall appearance of the assembly. Furthermore, the screw’s resistance to loosening helps maintain the integrity of the fastening over time, even under significant vibration and stress 3.

Installation and Usage Guidelines

Proper installation of this part is vital to ensure optimal performance and longevity. Begin by selecting the appropriate size hex key to match the screw’s socket. Insert the hex key into the socket and use a torque wrench to apply the recommended torque specification for the application. Ensure that the screw is installed perpendicular to the surface to avoid cross-threading and ensure a secure fit. Regularly inspect the screw for signs of wear or damage and replace it if necessary to maintain the integrity of the assembly.

Troubleshooting Common Issues

Frequent problems associated with Socket Head Cap Screws include loosening, corrosion, and damage to the socket. To address these issues, regularly inspect the screws for signs of wear or corrosion. If a screw appears loose, re-torque it to the manufacturer’s specifications. In cases of significant corrosion, replace the screw to prevent failure. If the socket is damaged, use a new hex key or replace the screw to ensure proper installation and function.

Maintenance Tips for Socket Head Cap Screws

To prolong the life of this part and maintain its effectiveness, implement regular inspection and care routines. Inspect the screws during routine maintenance checks for signs of wear, corrosion, or loosening. Clean the screws and surrounding areas to remove dirt and debris that could contribute to corrosion. Apply a corrosion-resistant coating if necessary to protect the screws from environmental factors. Replace any damaged or worn screws promptly to ensure the continued reliability of the assembly.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines, components, and systems. With a history spanning over a century, Cummins has established a reputation for innovation, reliability, and performance. The company offers a comprehensive range of products designed to meet the demanding requirements of heavy-duty truck applications, ensuring that commercial fleets operate efficiently and reliably.

Socket Head Cap Screw 3336452 in Cummins Engines

This part is a critical component in several Cummins engine models. It is integral to the assembly and maintenance of various engine systems, ensuring structural integrity and operational efficiency.

Application in Specific Engines

QSV81G and QSV91G Engines

In the QSV81G and QSV91G engines, this part is utilized in several key areas. These engines are known for their robust design and high performance, and the screw plays a vital role in maintaining the alignment and stability of various engine components. Its application in these models ensures that the engine’s internal parts remain securely fastened, contributing to the overall durability and longevity of the engine.

QSW/QSV82 Engines

For the QSW/QSV82 engines, this part is employed in both the engine block and the cylinder head assembly. This screw is essential for securing the cylinder head to the engine block, ensuring a tight seal that is crucial for maintaining engine performance and preventing leaks. Its use in these engines highlights its importance in achieving a precise and reliable fit.

QSW27 and QSW36 Engines

In the QSW27 and QSW36 engines, this part is used in multiple locations, including the engine block, cylinder head, and various other sub-assemblies. This screw is critical for maintaining the structural integrity of these engines, ensuring that all components are securely fastened and properly aligned. Its application in these models underscores its versatility and importance in the engine’s overall design.

QSW73 Engine

The QSW73 engine also relies on this part for several critical functions. This screw is used in the engine block and other key areas to ensure that all components are securely fastened and properly aligned. Its use in the QSW73 engine highlights its importance in achieving a precise and reliable fit, contributing to the engine’s overall performance and durability.

Grouping of Engines

This part is used across multiple Cummins engine models, including the QSV81G, QSV91G, QSW/QSV82, QSW27, QSW36, and QSW73 engines. Its application in these engines demonstrates its versatility and importance in ensuring the structural integrity and operational efficiency of the engine systems. Its use in these models highlights its critical role in maintaining the alignment and stability of various engine components, contributing to the overall performance and durability of the engines.

Role of Part 3336452 Socket Head Cap Screw in Engine Systems

This part is integral to the secure and efficient operation of various engine systems. It is commonly used in the arrangement of components to ensure they are held firmly in place, reducing the risk of movement or misalignment during engine operation.

In the turbocharger assembly, this screw plays a significant role in securing the turbocharger to the engine block, ensuring that the high-speed rotation of the turbocharger is stable and does not cause undue stress on the mounting points.

Within the ignition assembly, the Socket Head Cap Screw is used to fasten components such as the ignition coil to the cylinder assembly block, ensuring a reliable spark for combustion.

The blowby flow assembly sensor relies on this screw to maintain its position relative to the crankcase, allowing for accurate measurement of blowby gases which are essential for engine diagnostics and performance tuning.

In the charge air assembly cooler, the screw is utilized to secure the cooler to the plumbing, ensuring that the charge air remains cool and dense for optimal combustion efficiency.

The control linkage assembly lever is another area where this screw is vital. It ensures that the lever is securely attached to the control module assembly, allowing for precise control of engine functions.

The electronic control engine and electronic engine monitor systems often use this screw to mount various sensors and modules to the engine block, ensuring that these critical components remain in place and function correctly.

In the engine barring gear system, the Socket Head Cap Screw is used to secure the gear in place, allowing for easy rotation of the engine during maintenance procedures without causing damage.

The oil fill assembly arrangement and oil filter housing also benefit from the use of this screw, ensuring that these components are securely attached and do not leak oil during operation.

Lastly, in the starting assembly motor and system engine monitoring, the screw is used to secure various components, ensuring that the starting process is smooth and that monitoring systems remain accurately positioned for reliable data collection.

Conclusion

The Socket Head Cap Screw 3336452 is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its design and material properties make it suitable for heavy-duty applications, ensuring secure and durable connections in various mechanical assemblies. Proper installation, regular maintenance, and timely replacement of worn or damaged screws are essential to maintain the integrity and performance of the engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.