This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3336451 Socket Head Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is significant in the context of commercial truck maintenance and operation, providing reliable fastening solutions that contribute to the overall efficiency and safety of truck assemblies.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by a hexagonal socket in the head, allowing it to be driven using a hex key. These screws are commonly used in mechanical assemblies for their strength and ease of installation. They function by securely joining components together, distributing load evenly, and resisting loosening under vibration and dynamic loads 1.

Purpose of the 3336451 Socket Head Cap Screw in Truck Operation

This Cummins part plays a role in the operation and maintenance of commercial trucks by providing secure fastening in various truck components. Its applications range from engine assemblies to chassis parts, ensuring that critical components remain firmly in place under operational stresses.

Key Features

This part is designed with several key features that enhance its performance and durability. It is constructed from high-strength materials, ensuring resistance to wear and corrosion. The screw’s hexagonal socket head allows for efficient tightening and loosening using a hex key, while its cap design provides a smooth surface that reduces the risk of galling and seizing.

Benefits

Using this part offers several benefits. Its high-strength material composition contributes to improved reliability in truck assemblies. The design of the screw facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, the screw enhances structural integrity by providing a secure and durable fastening solution 2.

Installation Guidelines

Proper installation of this part involves several steps to ensure secure fastening. Begin by selecting the appropriate hex key for the screw size. Insert the screw into the pre-drilled hole, ensuring it is aligned correctly. Use the hex key to tighten the screw to the recommended torque specification, which can be found in the manufacturer’s guidelines. It is important to avoid over-tightening, as this can lead to damage or stripping of the screw or the surrounding material.

Maintenance and Troubleshooting

Maintaining this part involves periodic inspection for signs of wear, corrosion, or loosening. Cleaning the screw and its surrounding area can prevent the accumulation of debris that may affect its performance. Lubrication with a compatible lubricant can also help maintain the screw’s functionality. If loosening is detected, re-tightening to the recommended torque specification is advised. In cases of corrosion, the screw may need to be replaced to ensure continued reliability.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to manufacturing high-quality components is evident in its extensive product portfolio, which includes a wide range of engine and vehicle components designed to meet the demanding requirements of commercial truck operations.

Socket Head Cap Screw 3336451 in Cummins Engines

This Cummins part is a critical component in various Cummins engines, ensuring structural integrity and proper assembly. This screw is designed to provide a secure fastening solution, which is essential for maintaining the operational efficiency and safety of the engines.

Application in Specific Engines

QSV81G and QSV91G Engines:

In the QSV81G and QSV91G engines, 3336451 is utilized in several key areas. It is often found in the engine block, cylinder head, and other critical assemblies where a robust connection is necessary to withstand the high stresses and vibrations typical of these engines. The screw’s design ensures that these components remain tightly fastened, preventing any loosening that could lead to engine failure.

QSW/QSV82 Engines:

For the QSW/QSV82 engines, 3336451 plays a vital role in securing various engine parts. It is commonly used in the mounting of engine accessories and in the assembly of the engine block and cylinder head. The precision engineering of this screw ensures that all parts are held firmly in place, contributing to the overall reliability and longevity of the engine.

QSW27 and QSW36 Engines:

In the QSW27 and QSW36 engines, 3336451 is integral to the assembly of the engine block, cylinder head, and other critical components. Its use in these engines ensures that the parts remain securely fastened, which is crucial for maintaining the structural integrity of the engine under high operational loads.

QSW73 Engine:

The QSW73 engine also benefits from the use of 3336451. This screw is employed in the assembly of the engine block, cylinder head, and other key parts. Its design ensures that these components are held firmly in place, which is essential for the engine’s performance and durability.

QSZ90 Engine:

In the QSZ90 engine, 3336451 is used in several critical areas. It is often found in the engine block and cylinder head assemblies, where it provides a secure fastening solution. This screw’s precision engineering ensures that all parts are held tightly, contributing to the engine’s overall reliability and performance.

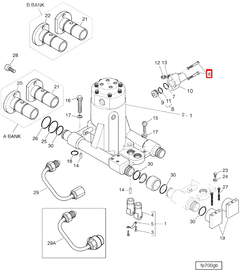

Role of Part 3336451 Socket Head Cap Screw in Engine Systems

This part is integral to the secure assembly and operation of various engine components. It is commonly used in the Assembly Control Bracket to ensure the structural integrity and precise alignment of control mechanisms. In the Assembly Gas Circuit, this screw helps in maintaining the tight seals necessary for efficient gas flow and pressure regulation.

Within the Assembly Ignition and Ignition Box Sub-Assembly, the Socket Head Cap Screw is employed to fasten ignition components, ensuring reliable spark delivery to the cylinders. The Block and Cylinder Assembly Block utilize this screw to secure critical components, contributing to the overall stability and performance of the engine.

In the Cylinder Sensor Assembly Block and ETR CNT Cense Mod Assy, the screw plays a role in attaching sensors and modules, which are vital for monitoring engine performance and making real-time adjustments. The Exhaust Assembly Manifold relies on this screw to secure manifold components, ensuring efficient exhaust flow and reduced emissions.

For the Fuel Assembly Plumbing and Fuel Injection S/Assembly Pump, the Socket Head Cap Screw is used to fasten fuel lines and injectors, guaranteeing consistent fuel delivery and pressure. In the Module Assembly Electronic and Control Module Assembly Electronic, it secures electronic components, ensuring they remain in place and function correctly under various operating conditions.

The Control Operating Engine and Monitor Electronic Engine systems use this screw to attach control modules and monitoring sensors, facilitating accurate data collection and engine management. In the Starting Assembly Motor and Motor Starting, it ensures that starting components are firmly in place, contributing to reliable engine start-up.

The Mounting Bracket Side B and Inlet Sub-Assembly Air depend on this screw to secure brackets and air intake components, respectively, ensuring proper air flow and component stability. The Pump Fuel Injection system uses it to fasten fuel pump components, maintaining efficient fuel pressure and delivery.

Overall, this part is a versatile fastener that enhances the reliability and performance of numerous engine systems by ensuring components are securely and precisely assembled.

Conclusion

The 3336451 Socket Head Cap Screw is a vital component in the maintenance and operation of commercial trucks, particularly in Cummins engines. Its design and material composition ensure reliable fastening, contributing to the overall efficiency and safety of truck assemblies. Proper installation, maintenance, and understanding of its applications are crucial for maximizing the benefits of this part in engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.