This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Socket Head Cap Screw 3336450, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty applications. This screw is integral to various truck assemblies, ensuring secure and reliable connections in critical components.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for efficient and precise tightening using a hex key. These screws are commonly used in mechanical assemblies where high strength and resistance to loosening are required. They function by providing a secure connection between parts, distributing load evenly, and resisting vibration and torque 1.

Purpose of Socket Head Cap Screw 3336450 in Truck Operations

The Socket Head Cap Screw 3336450 plays a specific role in the operation and maintenance of commercial trucks. It is utilized in applications where robust fastening is necessary, such as in engine components, transmission systems, and chassis assemblies. This screw helps maintain the integrity of these critical systems by providing a strong, durable connection that can withstand the rigors of heavy-duty use.

Key Features

The Socket Head Cap Screw 3336450 is distinguished by several key features. It is typically made from high-strength steel, ensuring durability and resistance to wear. The design includes a countersunk head that sits flush with the surface, reducing the risk of snagging and improving aesthetics. Additionally, it may feature special coatings or treatments to enhance corrosion resistance and further improve longevity in harsh environments.

Benefits

Using Socket Head Cap Screws in truck assemblies offers several advantages. These screws provide exceptional strength and durability, making them suitable for high-stress applications. Their design allows for easy installation and removal using a hex key, reducing the risk of damage to the screw head. Moreover, the countersunk head minimizes protrusion, enhancing both safety and appearance.

Installation Procedures

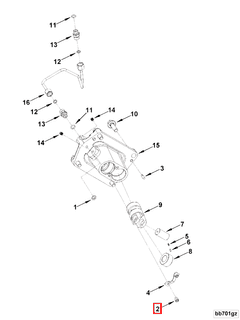

Proper installation of the Socket Head Cap Screw 3336450 is vital to ensure its function and longevity. Begin by cleaning the mating surfaces to remove any debris or contaminants. Use a hex key to drive the screw into the pre-drilled hole, ensuring it is perpendicular to the surface. Tighten the screw to the specified torque setting to avoid over-tightening, which can lead to stripping or damage. Regularly check the connection to ensure it remains secure over time 2.

Troubleshooting Common Issues

Frequent problems with Socket Head Cap Screws can include loosening due to vibration, corrosion, or damage from improper installation. To address these issues, regularly inspect screws for signs of wear or corrosion. If a screw appears loose, re-tighten it to the recommended torque specification. In cases of severe corrosion or damage, replacement may be necessary to maintain the integrity of the assembly.

Maintenance Tips

To prolong the service life of Socket Head Cap Screws and ensure reliable performance, regular maintenance is recommended. Inspect screws periodically for signs of wear, corrosion, or loosening. Clean the screws and surrounding areas to remove any buildup that could lead to corrosion. Applying a corrosion-resistant coating can further protect the screws from environmental factors. Additionally, ensure that all screws are tightened to the proper torque specification during routine maintenance checks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of heavy-duty applications.

Socket Head Cap Screw 3336450 in Cummins Engines

The Socket Head Cap Screw 3336450, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the assembly and maintenance of these engines, ensuring secure fastening and structural integrity.

15N CM2380 M104B

In the 15N CM2380 M104B engine, the Socket Head Cap Screw 3336450 is used to secure various components, ensuring that parts remain tightly fastened under operational stresses. Its design allows for precise torque application, which is crucial for maintaining the engine’s performance and longevity.

QSV81G, QSV91-G4, CM558/CM700 V102, QSV91G

For the QSV81G, QSV91-G4, CM558/CM700 V102, and QSV91G engines, this screw is employed in several key areas. It is used to fasten components that are subject to high vibration and thermal stress, ensuring that these parts remain securely in place. The screw’s robust design and material properties make it ideal for these demanding environments.

QSW/QSV82, QSW27, QSW36, QSW73, QSZ90

In the QSW/QSV82, QSW27, QSW36, QSW73, and QSZ90 engines, the Socket Head Cap Screw 3336450 plays a vital role in securing various engine components. Its use in these engines highlights its versatility and reliability in different engine configurations. The screw’s ability to withstand operational stresses makes it a preferred choice for these applications.

Z14 CM2670 Z103B

For the Z14 CM2670 Z103B engine, the Socket Head Cap Screw 3336450 is used to fasten components that require a high level of precision and durability. Its design ensures that these parts remain securely fastened, contributing to the overall reliability and performance of the engine.

Role of Part 3336450 Socket Head Cap Screw in Engine Systems

The part 3336450 Socket Head Cap Screw is integral to the secure assembly and operation of various engine components. Its applications span across multiple systems, ensuring the structural integrity and functional efficiency of the engine.

Assembly Governor

In the assembly governor, the Socket Head Cap Screw is used to fasten components that regulate the engine’s speed. This ensures that the governor operates smoothly and maintains consistent engine performance under varying loads.

Assembly Ignition and Ignition Boxes Sub-Assembly

For the assembly ignition and ignition boxes sub-assembly, these screws secure the ignition components, ensuring reliable spark delivery to the combustion chambers. This is essential for consistent engine starting and operation.

Block and Cylinder

Within the engine block and cylinder assembly, Socket Head Cap Screws are employed to fasten critical components such as cylinder heads and valve covers. This maintains the integrity of the combustion chamber and ensures proper sealing.

Cam Assembly Follower and Control Sub-Assembly Rod Push

These screws are vital in the cam assembly follower and control sub-assembly rod push systems. They secure the followers and push rods, which are responsible for opening and closing the valves in sync with the camshaft.

Cover and Front Gear

In the cover and front gear components, Socket Head Cap Screws are used to attach the front gear cover, ensuring that the gears operate within their housing without misalignment.

Drive and Front Gear Train Accessory

For the drive and front gear train accessory, these screws secure the accessory drive components, ensuring that auxiliary systems like the alternator and water pump are properly mounted and function efficiently.

Flywheel Assembly Housing and Flywheel Housing Assembly

In the flywheel assembly housing and flywheel housing assembly, Socket Head Cap Screws are critical for attaching the flywheel to the engine block. This ensures smooth power transmission from the engine to the transmission system.

Front Cover and Fuel Injection S/Assembly Pump

These screws are used in the front cover and fuel injection s/assembly pump to secure the fuel injection components. This is essential for precise fuel delivery and engine performance.

Gear Assembly Housing and Housing Flywheel

In the gear assembly housing and housing flywheel, Socket Head Cap Screws fasten the gear components, ensuring that the transmission of power between the engine and other mechanical parts is efficient and reliable.

Hydraulic Assembly Governor

For the hydraulic assembly governor, these screws secure the hydraulic components that control the governor’s operation, ensuring accurate and responsive engine speed regulation.

Lubricating Oil Assembly Plumbing and Oil Assembly Pan

In the lubricating oil assembly plumbing and oil assembly pan, Socket Head Cap Screws are used to secure oil passages and the oil pan, ensuring that the lubrication system functions correctly and maintains engine health.

Pan Oil and Pump Fuel Injection

These screws are essential in securing the pan oil and pump fuel injection components, ensuring that both the lubrication and fuel systems are properly mounted and operate efficiently.

Pump Fuel Inject. Subassy, Rocker Assembly Lever, and Valve Assembly Tappet

In the pump fuel inject. subassy, rocker assembly lever, and valve assembly tappet, Socket Head Cap Screws secure the fuel injection pump, rocker arms, and valve tappets. This ensures precise fuel injection and valve operation, contributing to overall engine performance.

Valve Tappet Assembly Housing

Finally, in the valve tappet assembly housing, these screws secure the tappet housing, ensuring that the valve train components are properly aligned and function smoothly.

Conclusion

The Socket Head Cap Screw 3336450 is a critical component in the assembly and maintenance of commercial trucks and Cummins engines. Its robust design, high-strength material, and precise installation procedures ensure secure fastening and structural integrity in various engine systems. Regular maintenance and proper installation are essential to prolong the service life of this screw and ensure reliable performance in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.