This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 3332175, is a specialized fastener produced by Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry. This screw is significant in commercial trucks due to its robust design and reliable performance in securing various components. Cummins, known for its high-quality diesel engines and components, ensures that this screw meets stringent industry standards.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient tightening and loosening using a wrench or socket, while the flange provides additional surface area for distribution of clamping force. This design is particularly effective in fastening applications where high torque and resistance to loosening are required.

Purpose and Role in Truck Operation

The 3332175 Hexagon Flange Head Cap Screw plays a specific role in the operation of commercial trucks by securing critical components and ensuring structural integrity. It is commonly used in applications where vibration and dynamic loads are present, such as in the engine compartment, transmission, and chassis. By providing a secure and stable connection, this screw helps maintain the alignment and functionality of various truck parts.

Key Features

The 3332175 Hexagon Flange Head Cap Screw features a hexagonal head design that facilitates easy and precise tightening. The flange beneath the head enhances the screw’s ability to distribute clamping force evenly, reducing the risk of component damage. Additionally, the screw is typically made from high-strength materials, such as alloy steel, which contributes to its durability and resistance to corrosion. These features collectively ensure reliable performance in demanding truck applications.

Benefits

Using the 3332175 Hexagon Flange Head Cap Screw in truck applications offers several benefits. The screw provides enhanced fastening strength, which is crucial for maintaining the integrity of truck components under heavy loads and dynamic conditions. Its design also offers resistance to loosening, ensuring that connections remain secure over time. Furthermore, the screw’s ease of installation and removal simplifies maintenance procedures, reducing downtime and enhancing operational efficiency.

Installation Guidelines

Proper installation of the 3332175 Hexagon Flange Head Cap Screw is vital for optimal performance and longevity. Begin by ensuring that the mating surfaces are clean and free of debris. Align the screw with the designated hole and start threading it by hand to avoid cross-threading. Use a torque wrench to tighten the screw to the specified torque value, which ensures that the correct clamping force is applied without over-tightening. Regularly check the screw for proper alignment and ensure that it is seated correctly on the flange.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include loosening due to vibration, corrosion, and wear. To address these issues, regularly inspect the screws for signs of damage or wear. If corrosion is present, clean the affected areas and apply a suitable anti-corrosive coating. Lubricating the threads and under-head area can also help maintain the screw’s performance. Replace any screws that show significant wear or damage to prevent potential failures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s commitment to excellence is reflected in its wide range of products, including the 3332175 Hexagon Flange Head Cap Screw, which is designed to meet the rigorous demands of commercial truck applications.

Hexagon Flange Head Cap Screw 3332175 in Cummins Engines

The Hexagon Flange Head Cap Screw part number 3332175, manufactured by Cummins, is a critical component in several of their engine models. This screw is integral to the assembly and maintenance of various engine parts, ensuring structural integrity and operational efficiency.

QSK38 CM850 MCRS and QSK60 CM850 MCRS

In the QSK38 CM850 MCRS and QSK60 CM850 MCRS engines, the 3332175 screw is used in applications where a secure fastening is required. These engines, known for their robust design, benefit from the screw’s ability to withstand high stress and maintain a tight seal, crucial for the engine’s performance and longevity.

QSK45 CM500 and QSK60 CM500

For the QSK45 CM500 and QSK60 CM500 engines, the 3332175 screw plays a pivotal role in the assembly of various engine components. Its design allows for easy installation and removal, which is essential during routine maintenance and repairs. The screw’s flange head provides a larger surface area for torque application, ensuring that the connection remains secure under operational conditions.

QSK50 CM2150 MCRS

In the QSK50 CM2150 MCRS engine, the 3332175 screw is utilized in critical areas where precise alignment and fastening are necessary. This engine’s design demands high reliability from its components, and the screw’s durability and strength make it an ideal choice for these applications.

QSK60 G CM2358 K110 and QSK60G

The QSK60 G CM2358 K110 and QSK60G engines also incorporate the 3332175 screw in their construction. These engines, known for their advanced technology and performance, rely on the screw’s precision and reliability to maintain the integrity of their components. The screw’s ability to handle high loads and maintain a tight fit is crucial for the smooth operation of these engines.

QSK78 CM500

In the QSK78 CM500 engine, the 3332175 screw is used in various applications where a strong and reliable fastening is required. This engine’s design benefits from the screw’s ability to provide a secure connection, ensuring that the engine operates efficiently and reliably.

QSK95 CM2350 K113

Finally, the QSK95 CM2350 K113 engine utilizes the 3332175 screw in its assembly. This engine, known for its high power output and durability, requires components that can withstand significant stress and maintain a secure connection. The screw’s design and material properties make it an excellent choice for these demanding applications.

Each of these engines, with their unique specifications and requirements, relies on the 3332175 screw to ensure that their components are securely fastened and that the engine operates efficiently and reliably.

Hexagon Flange Head Cap Screw (Part 3332175) Usage in Engine Systems

The Hexagon Flange Head Cap Screw, part number 3332175, is integral to the assembly and functionality of various engine systems. Its robust design ensures secure fastening in high-stress environments, making it suitable for multiple applications within engine components.

Accessories

In accessory systems, the Hexagon Flange Head Cap Screw is often used to mount and secure additional components such as sensors, gauges, and control units. Its flange head provides extra surface area for a firm grip, reducing the risk of loosening over time.

Electric Starting System

Within the electric starting system, this screw plays a role in attaching the starter motor to the engine block. It ensures that the starter motor remains firmly in place during operation, which is essential for reliable engine starts.

Crankcase Breather Arrangement

For the crankcase breather arrangement, the screw is utilized to secure breather tubes and valves. This helps maintain proper ventilation within the crankcase, preventing the buildup of pressure and contaminants.

Engine Lubrication Primer Arrangement

In the engine lubrication primer arrangement, the screw is employed to fasten the primer pump and related components. This ensures that the lubrication system operates efficiently, providing consistent oil flow to critical engine parts.

Rear Engine Support

The rear engine support system benefits from the use of this screw to attach support brackets and mounts. This enhances the structural integrity of the engine, especially during vibrations and high-performance operations.

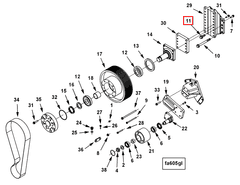

Fan Drive

For fan drives, the Hexagon Flange Head Cap Screw is used to secure the fan to the engine. This is vital for maintaining proper airflow and cooling, ensuring the engine operates within safe temperature ranges.

Heat Exchanger

In heat exchanger systems, the screw is utilized to fasten components such as radiators and intercoolers. This ensures that the heat exchanger remains securely in place, optimizing heat transfer and cooling efficiency.

Fuel Filter

The fuel filter arrangement uses this screw to mount the filter housing to the engine or fuel line. This secure attachment is important for maintaining a stable fuel supply and preventing leaks.

Flexplate and Flywheel

In the flexplate and flywheel assembly, the screw is used to attach these components to the crankshaft. This ensures smooth power transmission from the engine to the transmission system.

Thermostat Housing

For the thermostat housing, the screw is employed to secure the housing to the engine block. This is essential for maintaining the integrity of the cooling system and ensuring accurate temperature regulation.

Starting Motor

In starting motor applications, the screw is used to attach the motor to the engine. This secure fastening is necessary for reliable engine cranking and starting.

Fuel Supply Plumbing

Within the fuel supply plumbing system, the screw is utilized to secure fuel lines and fittings. This ensures a leak-free and stable fuel delivery system.

Engine Lubricating Primer

For the engine lubricating primer, the screw is used to fasten the primer pump and associated components. This ensures consistent oil pressure and lubrication during engine startup.

Fuel Transfer Pump

In fuel transfer pump systems, the screw is employed to secure the pump to the engine or fuel tank. This ensures reliable fuel transfer and pressure maintenance.

Base Support

The base support system uses this screw to attach the engine to its mounting frame. This provides a stable and secure foundation for the engine, enhancing overall performance and durability.

Rear Engine System

In the rear engine system, the screw is used to fasten various components such as exhaust manifolds and rear-mounted accessories. This ensures that all parts remain securely in place during operation.

Engine Cooling System

Within the engine cooling system, the screw is utilized to secure components such as the water pump and radiator mounts. This ensures efficient coolant flow and temperature management.

Conclusion

The 3332175 Hexagon Flange Head Cap Screw is a vital component in the assembly and maintenance of commercial truck engines, particularly those manufactured by Cummins. Its robust design, ease of installation, and resistance to loosening make it an ideal choice for securing critical components in high-stress environments. Proper installation and regular maintenance are essential to ensure the screw’s longevity and performance, contributing to the overall reliability and efficiency of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.