This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

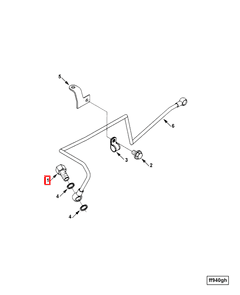

The 3281958 Banjo Connector Screw, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part facilitates the connection of hoses and pipes within the truck’s fluid transfer systems. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation, particularly in diesel engine manufacturing 1.

Function and Operation

This Cummins part operates by securely connecting hoses and pipes, which are integral to the fluid transfer systems in commercial trucks. It ensures the efficient and reliable transfer of fluids, such as hydraulic fluid or engine oil, throughout the system. By maintaining a secure connection, it helps preserve the integrity of the system, preventing leaks and ensuring consistent fluid flow 2.

Key Features

The design and construction of the 3281958 are tailored for durability and efficiency. It is crafted from high-quality materials, which contribute to its robustness and resistance to wear. The threading specifications are precise, ensuring a tight and secure fit. Additionally, unique attributes of its design enhance its performance, making it suitable for the demanding conditions found in commercial truck applications 3.

Benefits

Utilizing the 3281958 offers several advantages. It contributes to improved fluid dynamics within the system, ensuring efficient fluid transfer. Its design also enhances sealing capabilities, reducing the risk of leaks. Furthermore, the screw’s reliable performance contributes to the overall efficiency of the truck’s fluid transfer systems 4.

Installation Process

Proper installation of the 3281958 is crucial for its effective operation. The process involves aligning the screw with the corresponding fitting, applying the appropriate torque to secure it in place, and ensuring that all connections are tight and leak-free. Adhering to these steps helps guarantee a secure fit and optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the 3281958 is recommended to prolong its lifespan and ensure continued reliable operation. This includes periodic checks for signs of wear or damage, and tightening connections if necessary. Common issues may include leaks or loose connections, which can often be addressed through re-tightening or, in some cases, replacement of the screw.

Compatibility and Applications

The 3281958 is designed for use in various types of commercial trucks and is compatible with a range of fluid types and pressure conditions. Its versatility makes it a suitable choice for many applications within the commercial trucking industry.

Safety Considerations

When working with the 3281958, it is important to follow safety guidelines. This includes proper handling of the component, awareness of potential hazards such as fluid leaks or pressurized systems, and the use of necessary protective equipment to ensure personal safety during installation and maintenance procedures.

Cummins Overview

Cummins Inc. is a leader in the diesel engine manufacturing sector, with a history of innovation and a commitment to quality. The company’s expertise extends to a wide range of products and services for the automotive industry, including components like the 3281958, which are designed to meet the high standards of performance and reliability expected in commercial truck applications.

Cummins Banjo Connector Screw 3281958 in Engine Applications

The 3281958 is a critical component in the engine systems of various Cummins engines. This part is designed to secure the banjo fitting, ensuring a tight and leak-proof connection for hydraulic or fuel lines. Its application spans across several engine models, including the 6B5.9 and 6C8.3 engines.

6B5.9 Engine

In the 6B5.9 engine, the banjo connector screw is used to secure the banjo fitting on the fuel system. This ensures that the fuel lines remain connected without any leaks, which is crucial for maintaining optimal engine performance and fuel efficiency. The screw’s design allows for easy installation and removal, facilitating maintenance and repairs.

6C8.3 Engine

Similarly, in the 6C8.3 engine, the banjo connector screw plays a vital role in securing the banjo fitting on the hydraulic system. This is essential for maintaining the integrity of the hydraulic lines, which are critical for the engine’s operation. The screw’s robust construction ensures that it can withstand the pressures and stresses encountered in the engine environment, providing a reliable connection over time.

Grouping of Engines

Both the 6B5.9 and 6C8.3 engines benefit from the use of the banjo connector screw in their respective systems. While the 6B5.9 engine utilizes this part in the fuel system, the 6C8.3 engine incorporates it in the hydraulic system. Despite the different applications, the fundamental role of the screw remains the same: to provide a secure and leak-proof connection for the banjo fitting. This commonality highlights the versatility and importance of the part across various engine systems.

Role of 3281958 Banjo Connector Screw in Plumbing and Fuel Filter Systems

Plumbing Systems

In plumbing systems, the 3281958 is instrumental in ensuring secure and leak-free connections between various components. It is commonly used to join pipes, hoses, and fittings, particularly in high-pressure environments. The screw’s design allows for a tight seal, which is essential for maintaining the integrity of the plumbing system. This part is often found in applications where fluid transfer needs to be precise and reliable, such as in residential water supply lines, commercial irrigation systems, and industrial fluid transport networks. Its role in these systems is to provide a robust connection point that can withstand significant pressure fluctuations without compromising the seal.

Fuel Filter Systems

Within fuel filter systems, the 3281958 plays a significant role in connecting the fuel lines to the filter housing. This connection is vital for the efficient operation of the fuel system, as it ensures that fuel flows smoothly from the tank to the engine without leaks. The screw’s design facilitates easy installation and removal, which is beneficial during maintenance or replacement of the fuel filter. Additionally, it helps in maintaining a consistent fuel pressure, which is essential for the proper functioning of the engine. The secure connection provided by the Banjo Connector Screw prevents fuel leaks, which could otherwise lead to performance issues or safety hazards.

Conclusion

The 3281958 Banjo Connector Screw is a vital component in the fluid transfer systems of commercial trucks and various engine applications. Its design ensures secure and leak-proof connections, contributing to the efficient and reliable operation of these systems. Regular maintenance and proper installation are key to maximizing the lifespan and performance of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of the 3281958, making it a reliable choice for demanding commercial truck and engine applications.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Automotive Systems Principles and Practice, G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, CRC Press, 2011

↩ -

Charging the Internal Combustion Engine, Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Springer, 2010

↩ -

The Complete Vehicle, Michael Trzesniowski, Springer Nature, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.