3281476

Banjo Connector Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3281476 Banjo Connector Screw is a specialized component utilized in commercial trucks. It plays a role in both the hydraulic and fuel systems of these vehicles by facilitating the secure connection of hoses and pipes, ensuring the efficient transfer of fluids under pressure.

Basic Concepts and Functionality

A Banjo Connector Screw is a fitting used to connect hoses or pipes to various components within a truck’s system. It consists of a bolt with an integrated fitting that allows for the attachment of a hose or pipe via a banjo fitting. The design ensures a leak-proof connection, which is important for maintaining system integrity and performance. The screw operates by compressing a gasket between the fitting and the connected component, creating a seal that prevents fluid leakage.

Purpose and Role in Truck Operation

This Cummins part plays a role in the operation of a truck by ensuring the reliable connection of hydraulic and fuel lines. In the hydraulic system, it helps maintain the pressure required for the operation of brakes and other hydraulic components. In the fuel system, it ensures that fuel is delivered efficiently to the engine, contributing to overall performance and efficiency.

Key Features

The 3281476 is characterized by several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design includes precise threading and a robust fitting, which contribute to a secure and leak-proof connection. Additionally, the component may feature unique characteristics such as integrated gaskets or specialized coatings to further enhance its functionality and longevity.

Benefits

The use of this part offers several benefits in truck operations. It contributes to improved system efficiency by ensuring secure and leak-proof connections. The durable construction and high-quality materials enhance the component’s reliability, reducing the likelihood of failures and the need for frequent replacements. Furthermore, the secure connections provided by this component help maintain system pressure, which is vital for the optimal performance of hydraulic and fuel systems.

Installation and Usage

Proper installation of the 3281476 is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings to ensure a secure connection without over-tightening. It is also important to ensure that the mating surfaces are clean and free from debris to facilitate a proper seal. Regular inspection and maintenance can help ensure the longevity and proper function of the component.

Troubleshooting and Maintenance

Common issues associated with the 3281476 may include leaks or loose connections. Troubleshooting these issues may involve checking the torque settings, inspecting the gasket for damage, or ensuring that the mating surfaces are clean. Regular maintenance practices, such as periodic inspection and tightening of connections, can help prevent issues and ensure the component’s longevity and proper function.

Safety Considerations

When working with the 3281476, it is important to observe several safety guidelines and precautions. These may include wearing appropriate personal protective equipment, ensuring that the system is depressurized before making connections or disconnections, and following proper handling and installation procedures to prevent injuries or damage to the component.

Cummins Overview

Cummins is a renowned manufacturer with a rich history and a strong reputation in the industry. The company is committed to quality and innovation in automotive components, and their products, including the 3281476, are designed to meet the demanding requirements of commercial truck operations. Cummins’ dedication to excellence is evident in the performance, reliability, and durability of their components.

Engine Compatibility with Banjo Connector Screw Part 3281476

The Banjo Connector Screw part number 3281476, manufactured by Cummins, is a component in the fuel and fluid systems of various engines. This part is designed to ensure a secure and leak-proof connection in high-pressure environments, making it important for maintaining the integrity of the engine’s operation.

Cummins 4B3.9 Engine

In the Cummins 4B3.9 engine, the Banjo Connector Screw part 3281476 is utilized in the fuel delivery system. This engine, known for its robust performance, requires reliable connections to maintain fuel pressure and flow, ensuring optimal combustion and efficiency. The screw’s design allows for easy installation and removal, facilitating maintenance and repairs.

Cummins 6B5.9 Engine

Similarly, in the Cummins 6B5.9 engine, the Banjo Connector Screw part 3281476 plays a role in the engine’s hydraulic and fuel systems. This engine, designed for heavy-duty applications, demands components that can withstand high pressures and temperatures. The screw’s precision engineering ensures a tight seal, preventing leaks and maintaining system integrity.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines benefit from the use of the Banjo Connector Screw part 3281476 due to their shared requirement for reliable and high-performance connections in critical systems. Cummins’ design ensures that this part is compatible with these engines, providing a seamless fit and function that enhances the overall performance and longevity of the engines.

Role of Part 3281476 Banjo Connector Screw in Engine Systems

The Banjo Connector Screw, identified by part number 3281476, is a component in various engine systems, facilitating the secure connection of fuel lines and other critical systems. Its application spans across multiple components, ensuring efficient and reliable operation.

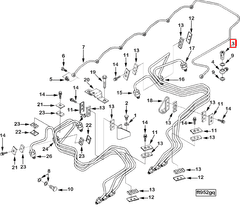

Fuel System Integration

In the fuel system, the Banjo Connector Screw is utilized to connect the fuel lines to the Bosch injection pump. This connection is vital for maintaining the integrity of the fuel delivery system, ensuring that fuel is transferred efficiently from the fuel tank to the injection pump. The screw’s design allows for a secure seal, preventing fuel leaks and maintaining system pressure.

Fuel Filter and Plumbing

The Banjo Connector Screw also plays a role in the fuel filter and fuel plumbing components. It connects the fuel lines to the fuel filter, ensuring that the fuel is properly filtered before reaching the engine. Additionally, it is used in fuel plumbing to connect various sections of the fuel lines, providing a reliable and leak-proof connection that is essential for the consistent flow of fuel.

Fuel Pump and Coupling

In the context of the fuel pump and its coupling, the Banjo Connector Screw is employed to connect the fuel lines to the fuel pump. This ensures that the fuel pump receives a steady supply of fuel, which is critical for its operation. The screw is also used in the fuel pump conversion kits, where it connects the new fuel lines to the existing system, facilitating a smooth transition and upgrade.

Air Fuel Control and Transfer

The Banjo Connector Screw is integral to the air fuel control system, where it connects the fuel lines to the components that regulate the air-fuel mixture. This connection is essential for maintaining the correct air-fuel ratio, which is crucial for engine performance and efficiency. Additionally, in fuel transfer systems, the screw is used to connect the fuel lines to the lift pump, ensuring that fuel is transferred efficiently from one location to another within the engine system.

Comprehensive System Support

Overall, the Banjo Connector Screw (part 3281476) supports a wide range of engine components, including accessories, fuel systems, and plumbing. Its reliable connection capabilities make it a fundamental part of ensuring that fuel is delivered efficiently and securely throughout the engine system.

Conclusion

The Cummins 3281476 Banjo Connector Screw is a critical component in the hydraulic and fuel systems of commercial trucks. Its design ensures secure and leak-proof connections, contributing to the efficient transfer of fluids under pressure. The part’s durable construction and high-quality materials enhance its reliability and longevity, making it a valuable component in maintaining the performance and efficiency of truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.