This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3280839 Flat Head Cap Screw is a specialized fastener designed for use in commercial trucks. Its purpose is to provide secure fastening in various truck components, ensuring the integrity and reliability of mechanical assemblies. This screw is particularly valued in the trucking industry for its robust construction and efficient performance in demanding environments.

Basic Concepts of Flat Head Cap Screws

Flat head cap screws are a type of fastener characterized by a flat, countersunk head that sits flush with or below the surface of the material being fastened. They are commonly used in mechanical assemblies where a low-profile head is required to reduce drag or for aesthetic reasons. These screws function by threading into a pre-drilled hole, creating a secure connection between components. Their design allows for efficient torque transfer and resistance to loosening under vibration 1.

Purpose of the 3280839 Flat Head Cap Screw in Truck Operation

The 3280839 Flat Head Cap Screw plays a role in the operation and maintenance of commercial trucks by securing critical components in place. It is often used in applications where a low-profile fastening solution is needed, such as in engine compartments, chassis assemblies, and various undercarriage components. Its functional importance lies in providing a reliable fastening mechanism that can withstand the rigors of heavy-duty truck operation.

Key Features of the 3280839 Flat Head Cap Screw

The 3280839 Flat Head Cap Screw is distinguished by several key features that enhance its performance and durability. It is typically made from high-strength materials, such as alloy steel, to ensure robustness under load. The screw features a specific thread type that provides optimal grip and resistance to loosening. Its design specifications, including the flat head and precise thread pitch, are tailored to meet the demanding requirements of commercial truck applications 2.

Benefits of Using the 3280839 Flat Head Cap Screw

Using the 3280839 Flat Head Cap Screw offers several advantages. It provides improved fastening security due to its high-strength material and precise thread design. The screw’s resistance to vibration helps maintain a secure connection in dynamic environments, reducing the risk of component failure. Additionally, its ease of installation, thanks to the flat head design, allows for efficient assembly and disassembly when needed 3.

Installation and Usage Guidelines

Proper installation of the 3280839 Flat Head Cap Screw involves several steps to ensure optimal performance. Begin by ensuring the mating surface is clean and free of debris. Use a drill bit slightly smaller than the screw diameter to create a pilot hole, which helps guide the screw and reduces the risk of stripping. Insert the screw and use a torque wrench to tighten it to the manufacturer’s specified torque settings. This ensures the screw is secure without over-tightening, which could damage the threads or the component being fastened.

Troubleshooting and Maintenance

Common issues with flat head cap screws include loosening due to vibration and corrosion from exposure to moisture or chemicals. To identify problems, regularly inspect screws for signs of movement or rust. Maintenance tips include applying a thread locker to prevent loosening and using corrosion-resistant coatings or materials to protect against environmental factors. Replacing screws that show signs of wear or damage can help prolong the lifespan of the fastening system.

Compatibility and Application

The 3280839 Flat Head Cap Screw is designed for use in various commercial truck systems. It is compatible with a range of components, including engine parts, chassis assemblies, and undercarriage elements. When selecting screws for specific applications, consider factors such as material compatibility, thread size, and environmental conditions to ensure optimal performance and longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the automotive industry. The company’s product range includes engines, powertrains, and related components for on-highway and off-highway applications, serving a variety of industries with reliable and efficient power solutions.

Cummins Flat Head Cap Screw 3280839 in Engine Applications

The Cummins Flat Head Cap Screw part number 3280839 is a critical component in several engine configurations, ensuring secure fastening and structural integrity. This screw is integral to the assembly and maintenance of the following engines:

6C8.3 Engine

In the 6C8.3 engine, the 3280839 Flat Head Cap Screw is utilized in various applications where a robust and reliable fastening solution is required. This engine, known for its durability and efficiency, relies on this screw to maintain the alignment and stability of its components, ensuring optimal performance and longevity.

C8.3 G Engine

Similarly, in the C8.3 G engine, the 3280839 Flat Head Cap Screw plays a vital role in securing different parts of the engine assembly. This engine variant, designed for heavy-duty applications, benefits from the strength and precision of this screw, which helps in maintaining the structural integrity of the engine under demanding conditions.

The use of the 3280839 Flat Head Cap Screw across these engines underscores its importance in ensuring the reliability and efficiency of the engine systems. This screw’s design and material properties make it suitable for high-stress environments, providing the necessary support and stability required for these engines to operate effectively.

Role of Part 3280839 Flat Head Cap Screw in Engine Systems

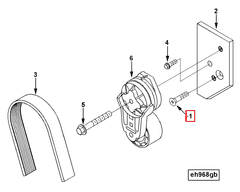

In the intricate assembly of engine systems, the Part 3280839 Flat Head Cap Screw serves as a fundamental fastening element, ensuring the secure attachment of various components. Its application is particularly notable in the context of the alternator drive and the alternator itself.

Alternator Drive

The alternator drive mechanism is responsible for converting mechanical energy from the engine into electrical energy, which is essential for powering the vehicle’s electrical systems and recharging the battery. The Part 3280839 Flat Head Cap Screw plays a significant role in this system by securing the alternator drive components. It ensures that the drive belt or chain remains taut and properly aligned, which is vital for efficient power transmission. The screw’s design allows for a snug fit, minimizing the risk of loosening due to vibrations, thereby maintaining consistent performance of the alternator drive.

Alternator

The alternator is a key component in the engine’s electrical system, generating electricity to supply the vehicle’s electrical needs and recharge the battery. The Part 3280839 Flat Head Cap Screw is used to fasten various parts of the alternator, such as the stator housing, rectifier assembly, and mounting brackets. By providing a reliable and durable connection, the screw helps to ensure that the alternator operates smoothly and efficiently. Its flat head design allows for a low-profile installation, which is often necessary in the compact and crowded environment of an engine compartment.

Conclusion

In summary, the Part 3280839 Flat Head Cap Screw is an essential component in the secure assembly and reliable operation of the alternator drive and alternator within engine systems. Its role in maintaining the integrity of these critical systems underscores the importance of using high-quality fastening solutions in automotive engineering.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.