This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

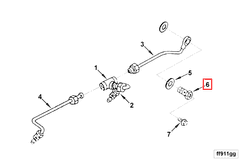

The 3279000 Banjo Connector Screw, manufactured by Cummins, is a specialized component used in the fluid systems of commercial trucks. Cummins, a well-established name in the automotive industry, is known for its high-quality engine and component manufacturing. This Cummins part is integral to the efficient operation of fluid systems in trucks, facilitating the transfer of fluids such as hydraulic oil and fuel. Understanding the role of banjo connector screws in these systems is fundamental to maintaining the performance and reliability of commercial vehicles .

Basic Concepts and Functionality

A banjo connector screw is a type of fitting used to connect hoses or pipes in fluid systems. Its basic design includes a bolt with an integrated fitting that allows for the attachment of hoses or pipes. The banjo connector screw functions by providing a secure and leak-proof connection between components in a fluid system. The components of a banjo connector screw typically include the bolt, a sealing washer, and a fitting that interfaces with the hose or pipe. These elements work together to ensure a tight seal and efficient fluid transfer .

Purpose and Role in Truck Operation

The 3279000 plays a role in the fluid systems of commercial trucks by ensuring secure and efficient connections between components. In hydraulic systems, it facilitates the transfer of hydraulic fluid, which is crucial for the operation of brakes, steering, and other hydraulic components. In fuel systems, it ensures a reliable connection for fuel lines, contributing to the efficient delivery of fuel to the engine. The proper function of these connections is vital for the overall performance and safety of the truck .

Key Features

The 3279000 is characterized by several key features that enhance its performance and reliability. It is constructed from high-quality materials that offer durability and resistance to corrosion. The design includes precision-machined threads and a robust fitting that ensures a secure connection. Additionally, the screw may feature unique characteristics such as enhanced sealing mechanisms or specialized coatings that improve its performance in demanding environments.

Benefits

The 3279000 offers several benefits that contribute to the overall performance and reliability of commercial trucks. Improved sealing capabilities reduce the risk of leaks, ensuring efficient fluid transfer and minimizing maintenance requirements. The durability of the screw ensures long-term reliability, even under harsh operating conditions. Ease of installation and maintenance further enhance its appeal, allowing for quick and straightforward replacements when necessary. These benefits collectively contribute to the efficient and reliable operation of the truck’s fluid systems.

Installation and Usage

Proper installation of the 3279000 is crucial for ensuring its performance and longevity. Cummins provides specific guidelines and recommended torque settings for installation, which should be followed to achieve a secure and leak-proof connection. This part is used in various fluid systems within a truck, including hydraulic and fuel systems. Careful attention to installation procedures ensures that the screw functions as intended, contributing to the efficient operation of the truck.

Troubleshooting and Maintenance

Common issues associated with banjo connector screws include leaks, corrosion, and wear. Troubleshooting these issues involves inspecting the connections for signs of damage or wear, ensuring that the screw is properly tightened, and replacing any damaged components as necessary. Regular maintenance, including inspections and replacements when needed, is important for ensuring the longevity and optimal performance of the 3279000. Following Cummins’ guidelines for maintenance helps to prevent issues and ensures the reliable operation of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, continually advancing its product offerings to meet the evolving needs of its customers. Cummins’ dedication to excellence is evident in its wide range of high-quality components, including the 3279000, which plays a role in ensuring the efficient and reliable operation of commercial trucks.

Conclusion

The 3279000 Banjo Connector Screw is a critical component in the maintenance and operation of various engine systems, ensuring secure and efficient connections in fuel, air intake, plumbing, and auxiliary systems. Its reliable performance is fundamental to the overall functionality and efficiency of the engine. Proper installation, regular maintenance, and adherence to Cummins’ guidelines are essential for maximizing the benefits of this part and ensuring the long-term reliability of commercial trucks.

: Crolla, David. *Crolla Encyclopedia*. Wiley, 2015.

: Ribbens, William B. *Understanding Automotive Electronics*. Elsevier Science, 2003.

: Pacejka, Hans B. *Tyre and Vehicle Dynamics*. Butterworth-Heinemann, 2006.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.