This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

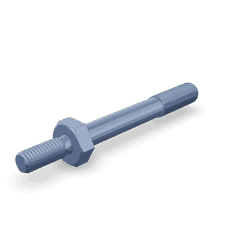

The 3255169 Studded Hexagonal Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is designed for use in commercial trucks, where it plays a role in securing various components and assemblies.

Basic Concepts of Studded Hexagonal Cap Screws

A studded hexagonal cap screw is a type of fastener characterized by a hexagonal head and a threaded shank that extends beyond the head, allowing it to be screwed into a tapped hole. These screws are commonly used in mechanical assemblies to secure components together. They function by providing a strong, reliable connection that can withstand significant stress and vibration, which is particularly important in the demanding environment of commercial truck operation 1.

Purpose of the 3255169 Studded Hexagonal Cap Screw in Truck Operation

This Cummins part is utilized in the operation and maintenance of commercial trucks to secure critical components. Its design allows it to provide a robust connection in areas where high tensile strength and resistance to loosening are required. This screw is often found in applications where components are subject to dynamic loads and vibrations, ensuring that parts remain securely fastened during operation 2.

Key Features

The 3255169 features a design that includes a hexagonal head for easy tightening and loosening with a wrench. It is made from high-quality materials that offer excellent durability and resistance to corrosion. The screw’s studded design allows for a longer engagement length, which can enhance the holding power and reduce the risk of stripping or pulling out.

Benefits

Using this part provides several benefits. Its robust construction contributes to improved durability and reliability in demanding applications. The ease of installation is another advantage, as the hexagonal head allows for straightforward tightening and loosening. Additionally, the material composition ensures resistance to environmental factors, which can extend the service life of the screw 3.

Installation Process

To install the 3255169, begin by ensuring that the mating threads are clean and free of debris. Align the screw with the tapped hole and start threading it in by hand to avoid cross-threading. Once the screw is started, use a wrench to tighten it to the manufacturer’s specified torque. It is important to avoid over-tightening, which can damage the threads or the component being secured.

Common Applications

Within the structure of a commercial truck, this part is typically used in applications such as securing engine components, attaching body panels, and fastening chassis parts. Its versatility and strength make it suitable for a wide range of uses where a secure and lasting connection is required.

Troubleshooting and Maintenance

To identify common issues with the 3255169, regularly inspect it for signs of wear, corrosion, or loosening. Maintenance tips include keeping the screw and surrounding area clean, and periodically checking the torque to ensure it remains within the specified range. If corrosion is present, consider applying a protective coating to prevent further degradation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range serves various industries, providing reliable and efficient power solutions.

Studded Hexagonal Cap Screw (Part 3255169) in Cummins Engines

The Studded Hexagonal Cap Screw, part number 3255169, is a critical component in various Cummins engines, ensuring secure fastening and stability. This part is integral to the assembly and maintenance of several engine models, providing a robust connection in high-stress environments.

ISL9 CM2150 SN, ISM CM570, ISM CM570/870, and QSM11 CM570

In the ISL9 CM2150 SN, ISM CM570, ISM CM570/870, and QSM11 CM570 engines, the studded hexagonal cap screw is used to secure various components, including engine mounts, brackets, and other structural parts. Its design allows for precise alignment and tight fastening, which is crucial for maintaining the integrity of the engine’s assembly.

M11 CELECT PLUS

For the M11 CELECT PLUS engine, the studded hexagonal cap screw is employed in similar applications, ensuring that critical components remain firmly attached. This is particularly important in the M11 CELECT PLUS, where reliability and performance are paramount.

QSC8.3 CM850 (CM2850) and QSC9 CM2250/QSL9 CM2250

In the QSC8.3 CM850 (CM2850) and QSC9 CM2250/QSL9 CM2250 engines, the studded hexagonal cap screw is used to secure various components, including engine mounts, brackets, and other structural parts. Its design allows for precise alignment and tight fastening, which is crucial for maintaining the integrity of the engine’s assembly. The screw’s studded design provides additional grip and stability, which is essential in these high-performance engines.

The studded hexagonal cap screw is a versatile and essential component in Cummins engines, ensuring that all parts are securely fastened and aligned. Its use across various engine models highlights its importance in maintaining the structural integrity and performance of these engines.

Role of Part 3255169 Studded Hexagonal Cap Screw in Engine Systems

In the intricate assembly of engine systems, the 3255169 serves as a fundamental fastening element, ensuring the secure attachment and alignment of various components.

At the alternator location, this screw is instrumental in mounting the alternator to the engine block or bracket, facilitating the alternator’s role in generating electrical power. Its studded design allows for a robust connection, capable of withstanding the vibrations and stresses encountered during engine operation.

Within the compressor assembly, particularly in systems utilizing refrigerant for cooling, the screw is used to secure the compressor housing. This ensures the integrity of the refrigerant pathways and the overall efficiency of the cooling system.

The harness and electronic control module wiring benefit from the screw’s secure fastening capabilities. It is employed to mount wiring harnesses and secure electronic control modules, ensuring that electrical connections remain stable and protected from environmental factors.

In the engine’s head assembly, the screw plays a part in securing components that are essential for combustion and valve operation. Its use here ensures that the head remains properly aligned and sealed, contributing to the engine’s performance and longevity.

For the oil filter cooler, the screw is utilized in the mounting process, ensuring that the cooler is securely attached and aligned within the engine’s plumbing system. This is vital for maintaining the efficiency of the oil cooling process, which is crucial for engine lubrication and heat management.

In plumbing applications, particularly where components need to be securely fastened within the engine’s fluid systems, the screw provides a reliable fastening solution. It ensures that connections remain tight and leak-free, which is essential for the proper functioning of the engine’s fluid systems.

Lastly, in the context of injector mounting, the screw is used to secure fuel injectors in place. This ensures that injectors are properly aligned and sealed, which is important for the precise delivery of fuel into the combustion chamber, directly impacting engine performance and fuel efficiency.

Conclusion

The 3255169 Studded Hexagonal Cap Screw is a vital component in the assembly and maintenance of commercial trucks and Cummins engines. Its robust design, ease of installation, and resistance to environmental factors make it an essential part for securing various components in demanding applications. Regular maintenance and proper installation are key to ensuring the longevity and reliability of this part in engine systems.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Robinson, Alan, and Livesey, Andrew. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.