3171693

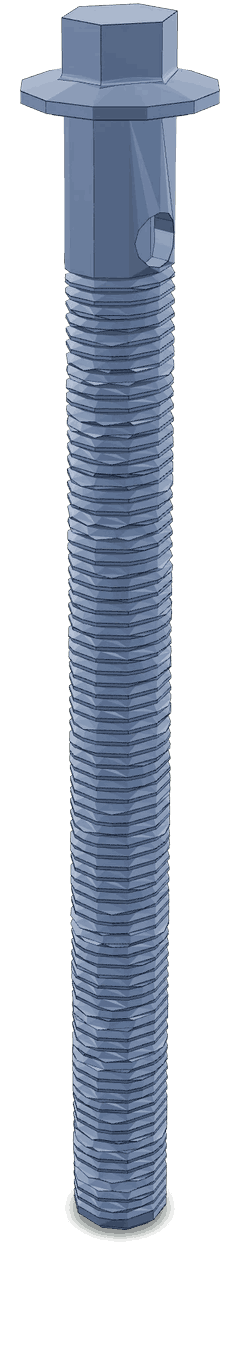

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3171693 Banjo Connector Screw, manufactured by Cummins, is a component used in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts designed to enhance the efficiency and reliability of truck systems. This part is significant in maintaining the integrity of fluid systems within trucks, ensuring smooth operation and performance.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems, such as hydraulic or fuel lines, to connect hoses or pipes. It typically consists of a bolt with an integrated fitting that allows for the secure attachment of a hose or pipe. The banjo fitting, which resembles a short tube with flanges on each end, is clamped between the bolt and a mating surface, creating a sealed connection. This design allows for easy installation and removal while providing a reliable seal against leaks 1.

Purpose of the 3171693 Banjo Connector Screw

The 3171693 Banjo Connector Screw plays a specific role in the operation of a truck by facilitating the connection of hydraulic or fuel lines. It ensures that fluids are transferred efficiently and securely throughout the system. This Cummins part is designed to withstand the pressures and conditions within these systems, contributing to the overall performance and reliability of the truck 2.

Key Features

The 3171693 Banjo Connector Screw is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, ensuring resistance to corrosion and wear. The thread type is designed for a secure fit, and the overall design of the screw promotes easy installation and maintenance. These features contribute to the screw’s ability to provide a reliable seal and withstand the demands of commercial truck operations 3.

Benefits

Using the 3171693 Banjo Connector Screw offers several benefits. It provides improved sealing, reducing the risk of leaks in the fluid system. The design of the screw allows for ease of installation, making it a practical choice for maintenance and repair tasks. Additionally, its resistance to corrosion and wear ensures longevity, contributing to the overall efficiency and reliability of the truck’s fluid systems.

Installation Process

Installing the 3171693 Banjo Connector Screw involves several steps to ensure a secure fit. First, the mating surface should be clean and free of debris. The screw should be threaded into the fitting until it is hand-tight, then further tightened using the appropriate tools to achieve the recommended torque specification. It is important to follow best practices, such as using a torque wrench, to ensure the connection is secure without over-tightening, which could damage the fitting or the screw.

Troubleshooting Common Issues

Common issues with Banjo Connector Screws may include leaks or connection failures. These problems can often be traced to improper installation, damage to the fitting or screw, or corrosion. Troubleshooting steps may involve inspecting the connection for signs of damage or wear, ensuring the screw is properly tightened, and replacing any damaged components. Regular maintenance and inspection can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3171693 Banjo Connector Screw, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the fitting and screw as part of routine maintenance can help prevent buildup that may lead to leaks or connection failures. Following manufacturer guidelines for torque specifications and installation practices will also contribute to the screw’s durability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range is designed to meet the demanding requirements of commercial operations, ensuring reliability, efficiency, and performance.

Integration of Part 3171693 in Cummins Engines

The Banjo Connector Screw, identified by part number 3171693, is a critical component in the Cummins engine lineup, specifically designed to ensure secure and leak-proof connections in various hydraulic and fuel systems. This part is integral to the operational integrity of the engines, providing a reliable method to attach hoses to the engine’s hydraulic and fuel lines.

Application in QSK45 CM500 and QSK60 CM500

In the QSK45 CM500 and QSK60 CM500 engines, the Banjo Connector Screw is utilized to maintain the integrity of the fuel and hydraulic systems. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The 3171693 part ensures that the connections to the fuel and hydraulic lines are tight and secure, preventing any leaks that could compromise engine performance or safety.

Application in QSK60G

The QSK60G engine also benefits from the use of the Banjo Connector Screw. This engine is part of Cummins’ lineup of high-output, heavy-duty diesel engines, designed for demanding applications. The 3171693 part is crucial in maintaining the reliability and efficiency of the engine’s hydraulic and fuel systems, ensuring that the connections remain secure under high-pressure conditions.

Grouping of Engines

The QSK45 CM500 and QSK60 CM500 engines can be grouped together due to their similar design and application focus. Both engines are designed for high-performance applications, and the use of the 3171693 part ensures that their hydraulic and fuel systems operate with maximum efficiency and reliability. The QSK60G, while part of the same family, is often used in even more demanding environments, and the 3171693 part plays a crucial role in maintaining the integrity of these systems under extreme conditions.

Role of Part 3171693 Banjo Connector Screw in Engine Systems

The 3171693 Banjo Connector Screw is integral to the efficient operation of various engine systems. Its primary function is to secure and seal connections in fuel and hydraulic systems, ensuring that fluids are delivered with precision and reliability.

In fuel injection systems, the Banjo Connector Screw is often used to connect the fuel rail to the injectors. This connection is vital for maintaining consistent fuel pressure and flow, which directly impacts the performance and efficiency of the injectors. A secure fit provided by the Banjo Connector Screw prevents leaks and ensures that the fuel delivery system operates smoothly.

Within hydraulic systems, such as those found in brake and clutch systems, the Banjo Connector Screw plays a similar role. It ensures that hydraulic fluid is transmitted effectively from the master cylinder to the actuators, maintaining the integrity of the hydraulic pressure. This is essential for the reliable operation of braking and clutch functions.

In terms of plumbing, the Banjo Connector Screw is used in various applications where fluid transfer is necessary. Its design allows for a robust connection that can withstand high pressures and vibrations, which are common in engine compartments. This reliability is key in preventing fluid leaks, which can lead to system failures or performance issues.

When considering alternative parts or design modifications, the Banjo Connector Screw’s role becomes even more apparent. Any changes to the connection points must maintain the same level of sealing and pressure integrity to ensure the system continues to function as intended.

Conclusion

Overall, the 3171693 Banjo Connector Screw is a fundamental component in ensuring the reliable and efficient operation of engine systems, contributing to both performance and safety.

-

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.