This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

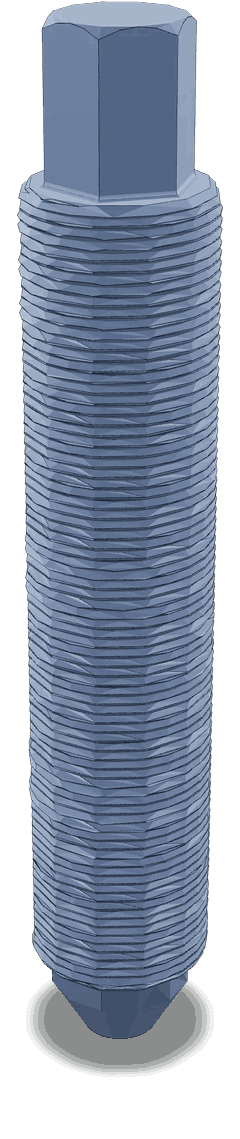

The Cummins 3164967 Replacer Screw is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the replacement of certain parts within the truck’s engine system, ensuring that maintenance procedures can be carried out efficiently and effectively. The significance of this screw in the maintenance and operation of commercial trucks lies in its ability to simplify the replacement process, thereby reducing downtime and enhancing the overall reliability of the vehicle 1.

Purpose and Function

The Cummins 3164967 Replacer Screw plays a role in the operation of a truck by providing a secure fit during the replacement of specific engine components. It is designed to be used in scenarios where original screws may be damaged or worn, ensuring that the replacement parts are installed correctly and securely. This contributes to the overall functionality of the vehicle by maintaining the integrity of the engine system and ensuring that all components are properly aligned and fastened 2.

Key Features

The Cummins 3164967 Replacer Screw is characterized by its robust design and high-quality material composition. It is crafted from durable materials to withstand the rigors of commercial truck operation, ensuring longevity and reliability. Unique characteristics of this screw include its precise threading and corrosion-resistant properties, which help to prevent loosening and damage over time. These features set it apart from other similar components, making it a preferred choice for maintenance professionals 3.

Benefits

Using the Cummins 3164967 Replacer Screw offers several benefits in commercial truck applications. It contributes to improved performance by ensuring that replacement parts are securely fastened, reducing the risk of component failure. The screw’s durability and reliability help to minimize the need for frequent replacements, saving time and resources. Additionally, its corrosion-resistant properties enhance the screw’s lifespan, providing long-term value in demanding operating environments 4.

Installation Process

Proper installation of the Cummins 3164967 Replacer Screw involves several steps to ensure a secure and effective fit. Begin by identifying the location where the screw is needed and prepare the area by cleaning any debris or old fasteners. Use the appropriate tools, such as a torque wrench, to install the screw, ensuring that it is tightened to the manufacturer’s specified torque settings. This helps to avoid over-tightening, which can damage the screw or the surrounding components, and under-tightening, which can lead to insecure fastening. Following best practices during installation will help to ensure the screw performs its intended function effectively 5.

Troubleshooting and Maintenance

To troubleshoot common issues related to the Cummins 3164967 Replacer Screw, first, ensure that it is installed correctly and tightened to the proper specifications. If the screw appears loose or damaged, it should be replaced promptly to prevent further complications. Regular maintenance practices, such as inspecting the screw for signs of wear or corrosion and ensuring that it remains securely fastened, can help to prolong its lifespan and ensure optimal performance. Additionally, keeping the surrounding area clean and free of debris can prevent contamination that may affect the screw’s functionality 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s product offerings include a wide range of engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial transportation. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name among fleet operators and maintenance professionals 7.

Role of Part 3164967 Replacer Screw in Engine Systems

The part 3164967 replacer screw is instrumental in ensuring the integrity and functionality of various engine components. One of its primary applications is in the crankshaft seal replacer system.

In this system, the replacer screw plays a significant role in maintaining the proper alignment and tension of the crankshaft seal. This seal is essential for preventing oil leaks and ensuring that the crankshaft operates smoothly within the engine block. The replacer screw helps to apply consistent pressure, which is necessary for the seal to perform its function effectively.

Additionally, the replacer screw is used in conjunction with other components such as gaskets and O-rings, enhancing their sealing capabilities. By securing these elements in place, the screw contributes to the overall reliability and performance of the engine.

Furthermore, the replacer screw is often employed in the assembly and disassembly processes of engine components. Its design allows for easy installation and removal, which is beneficial during maintenance or repair procedures. This feature not only saves time but also reduces the risk of damaging surrounding parts.

In summary, the part 3164967 replacer screw is a versatile component that supports the functionality of critical engine systems, ensuring they operate efficiently and reliably 8.

Conclusion

The Cummins 3164967 Replacer Screw is a critical component in the maintenance and operation of commercial trucks. Its robust design, precise threading, and corrosion-resistant properties ensure secure and reliable fastening of replacement parts, contributing to the overall performance and reliability of the vehicle. Proper installation and regular maintenance of this screw are essential to maximize its benefits and ensure the longevity of the engine system.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Cummins Inc. Operation and Maintenance Manual for F3.8 CM2620 F144B, Bulletin Number 5660039.

↩ -

Cummins Inc. Operation and Maintenance Manual for F3.8 CM2620 F144B, Bulletin Number 5660039.

↩ -

Cummins Inc. Operation and Maintenance Manual for F3.8 CM2620 F144B, Bulletin Number 5660039.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Operation and Maintenance Manual for F3.8 CM2620 F144B, Bulletin Number 5660039.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.