This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Twelve Point Cap Screw, identified by part number 3104435, is a specialized fastener produced by Cummins, a leading manufacturer in the automotive and heavy-duty truck industry. This component is integral to the assembly and maintenance of commercial trucks, ensuring secure and reliable fastening in various applications.

Basic Concepts of Twelve Point Cap Screws

A Twelve Point Cap Screw is a type of fastener characterized by its hexagonal socket head, which provides twelve points of contact. This design allows for more precise torque application compared to traditional hex-head screws, reducing the likelihood of cam-out—a situation where the driver slips out of the fastener head 1. The twelve-point design also offers a greater contact area, enhancing the screw’s resistance to stripping and providing a more secure hold 2.

Role of the 3104435 Twelve Point Cap Screw in Truck Operation

The 3104435 Twelve Point Cap Screw plays a significant role in the operation of commercial trucks by securing critical components and assemblies. It is commonly used in applications where high torque and secure fastening are required, such as in engine mounts, transmission housings, and chassis components. Its design ensures that these components remain firmly in place under the rigors of heavy-duty operation.

Key Features

The 3104435 Twelve Point Cap Screw is designed with several key features that enhance its performance and reliability. It is constructed from high-strength materials, typically alloy steel, to withstand the demanding conditions of commercial truck applications. The screw features a precision-machined twelve-point socket head, which allows for accurate torque application and reduces the risk of damage during installation. Additionally, the screw may include features such as a rolled thread for increased strength and corrosion-resistant coatings to enhance durability in harsh environments.

Benefits of Using a Twelve Point Cap Screw

Using a Twelve Point Cap Screw offers several advantages in commercial truck applications. The twelve-point design allows for more precise torque application, reducing the likelihood of over-tightening or under-tightening. This results in a more secure and reliable fastening solution. Additionally, the reduced cam-out risk ensures that the fastener remains engaged with the driver, minimizing the chance of damage to the screw head or surrounding components. The enhanced security provided by the twelve-point design also contributes to the overall durability and longevity of the fastening solution.

Installation Considerations

Proper installation of the 3104435 Twelve Point Cap Screw is crucial to ensure optimal performance and longevity. It is recommended to use the appropriate torque wrench to apply the specified torque values, ensuring that the screw is tightened to the manufacturer’s recommendations. Using the correct driver—typically a twelve-point socket—is also important to avoid damage to the screw head. Additionally, it is advisable to lubricate the threads with a suitable lubricant to reduce friction and prevent galling, especially in high-stress applications.

Maintenance and Troubleshooting

Regular maintenance of the 3104435 Twelve Point Cap Screw is important to ensure continued performance and reliability. Inspecting the screw for signs of wear, corrosion, or damage is recommended during routine maintenance checks. If any issues are detected, such as stripped threads or a damaged screw head, the screw should be replaced to prevent failure. Troubleshooting common issues, such as loose fasteners or difficulty in removal, may involve re-torquing the screw or using specialized tools to remove seized fasteners.

Manufacturer - Cummins

Cummins is a renowned manufacturer with a long-standing reputation for producing high-quality automotive components. Founded in 1919, Cummins has established itself as a leader in the industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive range of products, including engines, powertrains, and components, are designed to meet the demanding requirements of commercial truck applications. Cummins’ dedication to research and development ensures that their products, such as the 3104435 Twelve Point Cap Screw, incorporate the latest technologies and materials to deliver superior performance and reliability.

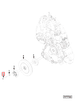

Role of Part 3104435 Twelve Point Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 3104435 Twelve Point Cap Screw serves as a fundamental fastening element, ensuring the secure attachment of various components. Its application is particularly significant in the integration of dampers and vibration control mechanisms.

Integration with Dampers

Dampers are essential in engine systems for absorbing and dissipating energy, thereby reducing oscillations and ensuring smooth operation. The Twelve Point Cap Screw, with its robust design, provides the necessary torque and resistance to keep damper components firmly in place. This secure fastening is vital for maintaining the damper’s efficiency and longevity, as any loosening could lead to diminished performance and increased wear.

Vibration Control Mechanisms

Engine systems are prone to vibrations, which if not managed properly, can lead to component fatigue and failure. The Twelve Point Cap Screw plays a key role in securing vibration control components, such as mounts and isolators, to the engine frame. By ensuring these components remain tightly fastened, the screw helps in maintaining the integrity of the vibration control system, thereby contributing to the overall stability and reliability of the engine.

Enhanced Performance and Durability

The use of the Twelve Point Cap Screw in these applications not only enhances the performance of the engine by ensuring components operate as intended but also contributes to the durability of the system. Its design allows for higher torque application without stripping, which is essential in high-stress environments typical of engine operations.

Conclusion

The 3104435 Twelve Point Cap Screw is instrumental in the secure and efficient operation of dampers and vibration control mechanisms within engine systems, playing a significant role in the overall performance and durability of the engine. Its precise design and robust construction make it a critical component in the assembly and maintenance of commercial trucks, ensuring reliable fastening in demanding applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.