This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagonal Flanged Head Cap Screw, identified by part number 3099833, is a specialized fastener produced by Cummins. This screw is integral to the assembly and maintenance of heavy-duty trucks, ensuring secure and reliable fastening in various applications. Cummins, a renowned manufacturer in the automotive industry, is known for its commitment to quality and durability in truck components 2.

Basic Concepts

A Hexagonal Flanged Head Cap Screw is characterized by its hexagonal head and a flanged feature near the head. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute load and prevent the screw from sinking into the material. This design is particularly effective in fastening applications where high torque and secure attachment are required 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of heavy-duty trucks. It is used in applications where secure fastening is crucial, such as attaching components to the truck’s frame or engine. The screw’s design ensures that it can withstand the rigors of heavy-duty use, providing a reliable connection that maintains integrity under stress and vibration.

Key Features

The 3099833 features a hexagonal head that facilitates easy and precise torque application. The flanged design near the head enhances the screw’s ability to distribute load and resist sinking into the material. Additionally, the screw is composed of high-quality materials, ensuring durability and resistance to corrosion, which is vital for long-term performance in demanding environments.

Benefits

Using this part offers several advantages. Its design enhances fastening security, providing a robust connection that can withstand significant stress. The ease of installation, thanks to the hexagonal head, allows for quick and efficient assembly. Furthermore, the screw’s durable material composition ensures longevity, reducing the need for frequent replacements and maintenance.

Installation Process

To install the 3099833, begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to apply the appropriate torque specification, ensuring the screw is tightened to the manufacturer’s recommended levels. This step is crucial to achieve optimal performance and longevity. Avoid over-tightening, as this can lead to damage or stripping of the screw or the material it is fastening.

Troubleshooting and Maintenance

Common issues with the 3099833 may include loosening over time due to vibration or corrosion. Regular inspection and maintenance can help identify and address these issues early. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can help prolong the screw’s lifespan. In cases of loosening, re-tightening to the specified torque or replacing the screw may be necessary.

Safety Considerations

When working with the 3099833, it is important to follow safety guidelines to ensure user safety and proper handling. Use appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against injury. Ensure that tools are in good condition and used correctly to avoid accidents. Additionally, always refer to the manufacturer’s instructions and torque specifications to prevent damage to the screw or the components being fastened.

Cummins Overview

Cummins is a leading manufacturer in the automotive industry, with a strong reputation for producing high-quality truck components. Founded in 1919, Cummins has a long history of innovation and excellence in engine and powertrain technology. The company is committed to delivering reliable and durable products that meet the demanding needs of heavy-duty truck applications. Cummins’ dedication to quality and performance is evident in their wide range of components, including the 3099833 2.

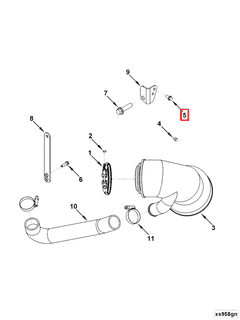

Hexagonal Flanged Head Cap Screw 3099833 in Cummins Engines

The 3099833, manufactured by Cummins, is a critical component in several of their engine models. This screw is integral to the assembly and maintenance of the engines, ensuring secure fastening and structural integrity.

QSM11 CM570

In the QSM11 CM570 engine, the 3099833 is used in various applications where a robust and reliable fastening solution is required. Its design allows for effective torque transmission and stability, which is crucial for maintaining the engine’s operational efficiency.

QSV91-G4 CM558/CM700 V102 and QSV91G

For the QSV91-G4 CM558/CM700 V102 and QSV91G engines, the 3099833 is employed in similar contexts. These engines benefit from the screw’s ability to withstand high stress and provide a secure connection, which is essential for the overall performance and longevity of the engine.

The use of the 3099833 across these engine models underscores its versatility and importance in Cummins’ engine designs. Its application in these engines highlights the importance of precision and reliability in engine components.

Role of Part 3099833 Hexagonal Flanged Head Cap Screw in Engine Systems

The 3099833 is integral to the assembly and operation of various engine components. Its design allows for secure fastening, which is essential for maintaining the integrity and efficiency of the engine system.

Connection Points

In engine systems, secure connections are paramount. The 3099833 is often used at connection points where components need to be firmly attached to ensure no movement or misalignment occurs during operation. This is particularly important in high-vibration environments typical of engine operation.

Exhaust Outlet

The exhaust outlet is a component where the 3099833 plays a significant role. It ensures that the exhaust manifold is securely fastened to the engine block. This connection must be robust to withstand the high temperatures and pressures generated during combustion.

Cooler Attachments

Engine coolers, whether for oil or transmission fluid, require stable mounting to the engine. The 3099833 is utilized to attach these coolers securely, ensuring they remain in place and function correctly to maintain optimal engine temperatures.

Engine Oil System

Within the engine oil system, the 3099833 is employed to fasten oil filters, oil pans, and other critical components. This ensures that the oil system remains sealed and operates efficiently, providing necessary lubrication to moving parts.

Support Structures

Engine support structures, such as brackets and mounts, often utilize the 3099833 to ensure they are securely attached to the engine frame. This is vital for maintaining the engine’s alignment and stability within the vehicle.

Front Engine Components

At the front of the engine, components such as the timing cover and front pulleys are often secured using the 3099833. This ensures that these components remain in the correct position, contributing to the overall precision and reliability of the engine’s operation.

Conclusion

The 3099833 Hexagonal Flanged Head Cap Screw is a vital component in the assembly and maintenance of heavy-duty trucks and Cummins engines. Its design ensures secure fastening, durability, and resistance to corrosion, making it an essential part for maintaining the integrity and efficiency of engine systems. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.