This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

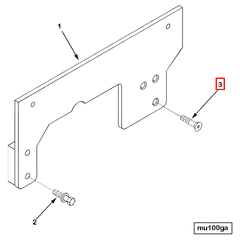

The Flat Head Cap Screw, specifically Part #3096045 by Cummins, is a vital component in the maintenance and assembly of commercial trucks. Cummins, a well-established manufacturer in the industry, produces this screw to meet the demanding requirements of heavy-duty applications. This overview will delve into the specifics of the Flat Head Cap Screw, its design, functionality, and the role it plays in truck operations.

Basic Concepts of Flat Head Cap Screws

A Flat Head Cap Screw is a type of fastener characterized by a countersunk head, which allows it to sit flush with or below the surface of the material being fastened. This design is particularly useful in applications where a smooth surface is required. The screw functions by converting torque applied to its head into a clamping force, which holds materials together securely. The countersunk head also facilitates easier installation in tight spaces and reduces the risk of the screw head protruding and causing damage or interference 1.

Purpose of the 3096045 Flat Head Cap Screw in Truck Operation

This Cummins part is designed to play a specific role in the assembly and maintenance of commercial trucks. It is used in various applications where secure fastening is required, such as attaching panels, securing components, and ensuring the integrity of truck assemblies. Its design allows for efficient and reliable fastening, which is crucial in the high-stress environments typical of commercial truck operations.

Key Features of the 3096045 Flat Head Cap Screw

The 3096045 is engineered with several key features that make it suitable for heavy-duty applications. These include a high-strength material composition, typically a grade of steel that offers excellent tensile strength and durability. The screw also features a precise thread pitch and robust construction, ensuring it can withstand significant loads and stresses. Additionally, the countersunk head design allows for a flush fit, which is important for both aesthetic and functional reasons in truck assemblies.

Benefits of Using the 3096045 Flat Head Cap Screw

Using this part offers several advantages. Its high-strength material provides durability, making it resistant to wear and tear even under heavy loads. The screw’s design also offers resistance to corrosion, which is particularly beneficial in outdoor and harsh environments. Furthermore, the ease of installation, thanks to its countersunk head, allows for quick and efficient fastening, reducing downtime during maintenance procedures 2.

Installation Guidelines

Proper installation of the 3096045 is crucial for ensuring optimal performance and longevity. Begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to apply the appropriate amount of torque specified by the manufacturer to avoid over-tightening, which can strip the threads, or under-tightening, which can lead to insufficient clamping force. It is also advisable to use a thread locker for additional security in vibration-prone applications.

Troubleshooting Common Issues

Common issues with Flat Head Cap Screws can include stripping, corrosion, and loosening over time. If a screw becomes stripped, it may need to be replaced. Corrosion can often be prevented with the use of corrosion-resistant coatings or materials. For screws that loosen over time, re-tightening or the application of a thread locker can help maintain the required clamping force.

Maintenance Tips

Regular maintenance of the 3096045 can prolong its life and ensure continued reliable performance. Inspect screws periodically for signs of wear, corrosion, or loosening. Clean the screws and surrounding areas to remove any buildup that could affect performance. Re-torque screws as needed to maintain the proper clamping force, especially after significant vibrations or impacts.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has built a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of various industries, including transportation, construction, and agriculture. Cummins’ commitment to innovation and customer satisfaction has solidified its position as a trusted name in the industry.

Role of Part 3096045 Flat Head Cap Screw in Engine Systems

This part is an essential component in the assembly and maintenance of various engine systems. Its primary function is to secure and fasten components together, ensuring stability and integrity under operational conditions.

Muffler Assembly

In the muffler assembly, the Flat Head Cap Screw is utilized to attach the muffler to the exhaust pipe. This connection is vital for maintaining the structural integrity of the exhaust system. The screw ensures that the muffler remains securely fastened, preventing vibrations and potential detachment during engine operation. Additionally, it helps in sealing the connection, which is important for the efficient flow of exhaust gases and reduction of noise emissions.

Exhaust Manifold Attachment

The Flat Head Cap Screw also plays a significant role in attaching the exhaust manifold to the engine block. This attachment is necessary for the proper channeling of exhaust gases from the cylinders to the exhaust system. The screw ensures a tight and secure fit, which is essential for maintaining the manifold’s position and preventing leaks that could affect engine performance and emissions.

Turbocharger Mounting

In turbocharged engine systems, the Flat Head Cap Screw is used to mount the turbocharger to the engine block or manifold. This secure attachment is important for the turbocharger’s operation, as it must withstand high temperatures and pressures. The screw ensures that the turbocharger remains firmly in place, allowing it to function efficiently without the risk of detachment or misalignment.

Heat Shield Fastening

Heat shields are often employed in engine systems to protect surrounding components from excessive heat. The Flat Head Cap Screw is used to fasten these heat shields in place. This ensures that the shields remain effective in their role, providing a barrier against heat transfer and protecting critical engine parts from damage.

Catalytic Converter Securement

The catalytic converter, a key component in reducing harmful emissions, is also secured using Flat Head Cap Screws. These screws attach the catalytic converter to the exhaust system, ensuring it stays in position and functions correctly. Proper securement is essential for the converter’s efficiency in converting exhaust gases into less harmful substances.

Conclusion

In summary, the 3096045 Flat Head Cap Screw is a versatile and reliable fastener in engine systems, contributing to the secure and efficient operation of various components. Its design and features make it well-suited for the demanding conditions of commercial truck operations, ensuring durability, resistance to corrosion, and ease of installation. Proper installation, maintenance, and troubleshooting are key to maximizing the performance and longevity of this critical component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.