3094521

Twelve Point Cap Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Twelve Point Cap Screw, Part #3094521, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this component to meet the demanding requirements of heavy-duty applications. This screw plays a significant role in ensuring the secure attachment of various components within the truck’s structure.

Basic Concepts of Twelve Point Cap Screws

A Twelve Point Cap Screw is a type of fastener characterized by its twelve-sided socket head. This design sets it apart from traditional hex cap screws, which have six sides. The twelve-sided configuration allows for a greater contact area between the tool and the screw head, which can result in more efficient torque application and reduced cam-out during tightening. These screws are commonly used in mechanical assemblies where high torque and secure fastening are required 1.

Purpose and Role in Truck Operation

The Twelve Point Cap Screw, Part #3094521, is utilized in commercial trucks to secure various components, contributing to the overall structural integrity of the vehicle. Its role involves fastening parts that are subject to significant stress and vibration, ensuring that they remain securely in place under operating conditions. This is particularly important in heavy-duty trucks, where the failure of a fastener could lead to serious mechanical issues 2.

Key Features

The Twelve Point Cap Screw, Part #3094521, features a twelve-sided socket head, which provides several advantages over traditional hex cap screws. This design allows for greater torque application without the risk of the tool slipping off the screw head, a phenomenon known as cam-out. Additionally, the increased number of sides enhances the grip, making it less likely for the screw to strip during installation or removal 3.

Benefits

Using the Twelve Point Cap Screw, Part #3094521, offers several benefits. The design of the screw head facilitates improved torque application, which is crucial for securing components in high-stress environments. The enhanced grip reduces the likelihood of stripping, ensuring a more reliable fastening solution. Furthermore, the resistance to cam-out during tightening contributes to a more secure and durable attachment.

Installation Considerations

Proper installation of the Twelve Point Cap Screw is vital to ensure secure fastening. It is important to adhere to the specified torque values provided by the manufacturer to avoid over-tightening, which can damage the screw or the components being fastened. Using the appropriate tool for the screw head size is also recommended to prevent damage and ensure a snug fit.

Troubleshooting Common Issues

Common issues with Twelve Point Cap Screws may include loosening due to vibration or corrosion over time. To address loosening, it may be necessary to re-tighten the screw or apply a thread locker to enhance its holding power. Corrosion can be mitigated by selecting screws made from materials resistant to the environmental conditions the truck operates in, or by applying a protective coating.

Maintenance Tips

Regular maintenance of Twelve Point Cap Screws is important to ensure their longevity and reliable performance. This includes periodic inspection for signs of wear or damage, such as corrosion or stripping. Screws that show signs of deterioration should be replaced to maintain the integrity of the fastened components. Additionally, ensuring that all screws are properly torqued during routine maintenance checks can help prevent issues related to loosening.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality and innovation. The company’s history of producing reliable components for commercial vehicles underscores its dedication to meeting the needs of its customers with durable and high-performance parts.

Twelve Point Cap Screw 3094521 in Cummins Engines

The Twelve Point Cap Screw 3094521, manufactured by Cummins, is a critical component in various Cummins engine models. This screw is integral to the assembly and maintenance of the engines, ensuring secure fastening and stability.

QST30 CM2350 T101 and QST30 CM552

In the QST30 CM2350 T101 and QST30 CM552 engines, the Twelve Point Cap Screw 3094521 plays a vital role in maintaining the structural integrity of the engine. This screw is used in several key areas where high strength and durability are required. It is often employed in the engine block, cylinder head, and other critical assemblies where it must withstand significant mechanical stress and thermal variations.

The precision and quality of the Twelve Point Cap Screw 3094521 ensure that it provides a reliable connection, reducing the risk of loosening or failure under operational conditions. This screw’s design, with its twelve points, allows for better grip and torque application, which is essential for the demanding environments these engines operate in.

The use of this screw in these engines highlights Cummins’ commitment to quality and reliability, ensuring that the engines perform optimally and maintain their integrity over time.

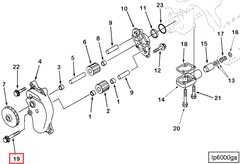

Component Usage of Twelve Point Cap Screw 3094521

The Twelve Point Cap Screw 3094521 is instrumental in ensuring the secure assembly and reliable operation of various engine system components.

In the lever mechanism, this cap screw is used to fasten the lever to its mounting bracket, ensuring that the lever operates smoothly and without undue play. This is essential for precise control and consistent performance.

For the rocker assembly, the Twelve Point Cap Screw is employed to attach the rocker to its base. This secure attachment is vital for maintaining the alignment and stability of the rocker, which is necessary for accurate valve operation in the engine.

In the context of mounting various engine components, the Twelve Point Cap Screw provides a robust connection between parts. Whether it is securing a component to the engine block or attaching auxiliary systems, this cap screw ensures that the mounting is firm and resistant to vibration.

The instrument panel often requires precise and secure fastening to ensure accurate readings and safe operation. The Twelve Point Cap Screw is utilized here to attach the panel to the dashboard, guaranteeing that it remains in place under various driving conditions.

In the pump system, particularly for fuel or lubricating oil pumps, the Twelve Point Cap Screw is used to secure the pump housing and internal components. This ensures that the pump operates efficiently without leaks or component misalignment.

Lastly, in the lubricating oil system, the Twelve Point Cap Screw plays a role in securing oil filters, fittings, and other components. This is important for maintaining the integrity of the lubrication system, ensuring that oil is distributed effectively throughout the engine.

Conclusion

The Twelve Point Cap Screw, Part #3094521, is a critical component in the assembly and maintenance of commercial trucks and Cummins engines. Its unique design provides enhanced torque application, reduced cam-out, and improved grip, making it a reliable fastening solution for high-stress environments. Proper installation, regular maintenance, and addressing common issues such as loosening and corrosion are essential to ensure the longevity and performance of this part. Cummins’ commitment to quality and innovation is evident in the design and application of this Twelve Point Cap Screw, ensuring that it meets the demanding requirements of heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.