3094512

Hexagon Flange Head Cap Screw

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins part number 3094512, a Hexagon Flange Head Cap Screw, is a vital component in the realm of commercial trucks. This screw is designed to meet the rigorous demands of heavy-duty applications, ensuring reliable performance and durability. Cummins, a well-respected name in the industry, produces this part with precision engineering and high-quality materials, making it a trusted choice for truck manufacturers and maintenance professionals.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and flanged base. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute load and prevent the screw from sinking into the material. In a truck’s mechanical system, these screws are used to secure various components, ensuring they remain firmly in place despite the vibrations and stresses encountered during operation.

Purpose and Role

This Cummins part serves a specific purpose in the operation of a truck. It is employed in applications where secure fastening is required, such as attaching brackets, panels, and other structural elements. Its design allows it to withstand significant loads and vibrations, making it suitable for use in engine compartments, chassis assemblies, and other critical areas where reliability is paramount.

Key Features

The 3094512 Hexagon Flange Head Cap Screw boasts several key features that contribute to its performance and durability. Its hexagonal head design enables easy and precise tightening with common tools, reducing the risk of damage to the screw or surrounding components. The flange at the base of the screw provides additional stability and load distribution, preventing the screw from pulling through the material. Additionally, the screw is crafted from high-strength materials, ensuring it can endure the harsh conditions of commercial truck operation.

Benefits

The benefits of using the 3094512 Hexagon Flange Head Cap Screw are manifold. Its design enhances fastening security, providing a robust connection that resists loosening due to vibration. The ease of installation and removal is another significant advantage, allowing for quick and efficient maintenance procedures. Furthermore, the screw’s durable construction ensures long-term reliability, reducing the need for frequent replacements.

Installation Process

Proper installation of the 3094512 Hexagon Flange Head Cap Screw is crucial for ensuring its effectiveness and longevity. Begin by selecting the appropriate size and grade of screw for the application. Use a torque wrench to apply the recommended torque specification, avoiding over-tightening which can lead to stripping or damage. Ensure the surfaces are clean and free of debris to promote a secure connection. It is also beneficial to apply a thread locker to prevent loosening over time.

Troubleshooting and Maintenance

Common issues with the 3094512 Hexagon Flange Head Cap Screw may include loosening or corrosion. Regular inspection and maintenance can help identify and address these problems early. If loosening is detected, re-torque the screw to the specified value and consider applying a thread locker. In cases of corrosion, remove the screw, clean the affected area, and replace the screw if necessary. Proper maintenance practices will help ensure the screw continues to perform reliably.

Cummins Overview

Cummins Inc. is a globally recognized leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has built a reputation for innovation, quality, and reliability. The company’s product range includes engines, filtration systems, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial truck applications. The 3094512 Hexagon Flange Head Cap Screw is a testament to Cummins’ commitment to providing high-quality, durable components for the industry.

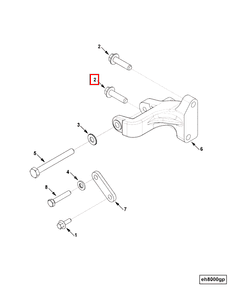

Cummins Engine Part 3094512: Hexagon Flange Head Cap Screw

The Cummins part number 3094512, a Hexagon Flange Head Cap Screw, is a critical component used across various Cummins engine models. This screw is designed to provide secure fastening in applications where a robust and reliable connection is essential. Below is a detailed description of how this part fits into the specified engines:

Cummins 6B5.9 and 6C8.3 Engines

In the 6B5.9 and 6C8.3 engines, the Hexagon Flange Head Cap Screw is used in several key areas. It is often employed in the cylinder head assembly, ensuring that the head is securely fastened to the engine block. This screw helps maintain the integrity of the combustion chamber and prevents leaks, which is crucial for engine performance and longevity.

Cummins B3.3 and QSB3.3 Engines

For the B3.3 and QSB3.3 engines, the part 3094512 is utilized in various mounting and assembly points. It is commonly found in the engine block, where it secures components such as the intake manifold and exhaust manifold. Additionally, it is used in the mounting of ancillary parts like the alternator and power steering pump, ensuring these components remain firmly in place under operational stresses.

Cummins B6.7S and QSB3.3 CM2150 SN Engines

In the B6.7S and QSB3.3 CM2150 SN engines, the Hexagon Flange Head Cap Screw is integral to the assembly of the turbocharger system. It is used to secure the turbocharger housing to the engine block, ensuring that the turbocharger operates efficiently and reliably. This screw is also used in the mounting of the fuel injection pump and other critical components, providing the necessary stability and alignment.

Cummins QSB3.3 CM2250 EC and QSB4.5 CM850 (CM2850) Engines

For the QSB3.3 CM2250 EC and QSB4.5 CM850 (CM2850) engines, the part 3094512 is employed in the assembly of the engine’s cooling system. It is used to secure radiators, coolant hoses, and other cooling components, ensuring that the engine maintains optimal operating temperatures. Additionally, it is used in the mounting of the engine’s electrical components, such as the alternator and sensor housings.

Cummins QST30 CM2350 T101 and QST30 CM552 Engines

In the larger QST30 CM2350 T101 and QST30 CM552 engines, the Hexagon Flange Head Cap Screw is used in the assembly of the engine’s main structural components. It is crucial in securing the engine block to the engine stand and other mounting points. This screw is also used in the assembly of the engine’s exhaust system, ensuring that all components are securely fastened and properly aligned.

The use of the Cummins part number 3094512 across these engines highlights its versatility and importance in maintaining the structural integrity and operational efficiency of Cummins engines.

Role of Part 3094512 Hexagon Flange Head Cap Screw in Engine Systems

The 3094512 Hexagon Flange Head Cap Screw is integral in securing various components within engine systems, ensuring both stability and efficient operation. Its applications span across multiple critical areas:

Turbocharger and Compressor Systems

In turbocharger and compressor setups, the Hexagon Flange Head Cap Screw is used to fasten components such as the turbocharger housing to the engine block or manifold. This secure attachment is vital for maintaining the integrity of the turbocharger’s operation, which relies on precise alignment and robust connections to optimize air flow and pressure.

Refrigerant and Air Crossover Connections

For systems involving refrigerant flow or air crossover, the screw ensures that connections remain leak-free and secure. This is particularly important in maintaining the efficiency of air conditioning systems and ensuring that refrigerant pathways do not develop leaks, which could compromise cooling performance.

Air Intake and Exhaust Outlet Connections

Within the air intake and exhaust outlet systems, the Hexagon Flange Head Cap Screw plays a role in securing connections that are exposed to varying pressures and temperatures. Its use here helps in maintaining a sealed environment, which is essential for the efficient operation of the engine by ensuring that air intake is unobstructed and exhaust is effectively expelled.

Engine Control Module and Wiring Harness Mounting

The screw is also employed in the mounting of the Engine Control Module (ECM) and its associated wiring harness. Securely fastening the ECM ensures that it remains in place under the vibrations and movements typical of engine operation, while also protecting the delicate electronic components within.

Exhaust Manifold and Fuel Pump Mounting

In the exhaust manifold and fuel pump mounting applications, the Hexagon Flange Head Cap Screw provides the necessary strength to withstand the high temperatures and pressures associated with these components. This secure attachment is essential for the durability and performance of the exhaust system and fuel delivery.

Plumbing for Air-Fuel Control and Engine Control Module

When it comes to the plumbing of air-fuel control systems and the ECM, the screw ensures that all connections are tight and secure. This is crucial for maintaining the precise control over air-fuel ratios, which directly impacts engine performance and emissions.

Alternator and Turbocharger Mounting

Finally, in alternator and turbocharger mounting applications, the Hexagon Flange Head Cap Screw ensures that these components are firmly attached to the engine. This secure attachment is vital for the efficient operation of the alternator in generating electrical power and for the turbocharger in enhancing engine performance through forced induction.

Conclusion

The 3094512 Hexagon Flange Head Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks and various Cummins engine models. Its robust design, ease of installation, and durable construction make it an essential part for ensuring the reliability and efficiency of engine systems. Proper installation and maintenance of this screw are vital for its longevity and continued performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.